Hot filament and heat evaporation vapor deposition membrane equipment

A vapor deposition and chemical vapor deposition technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of inability to carry out thermal evaporation treatment process at the same time, to avoid air pollution, improve yield, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

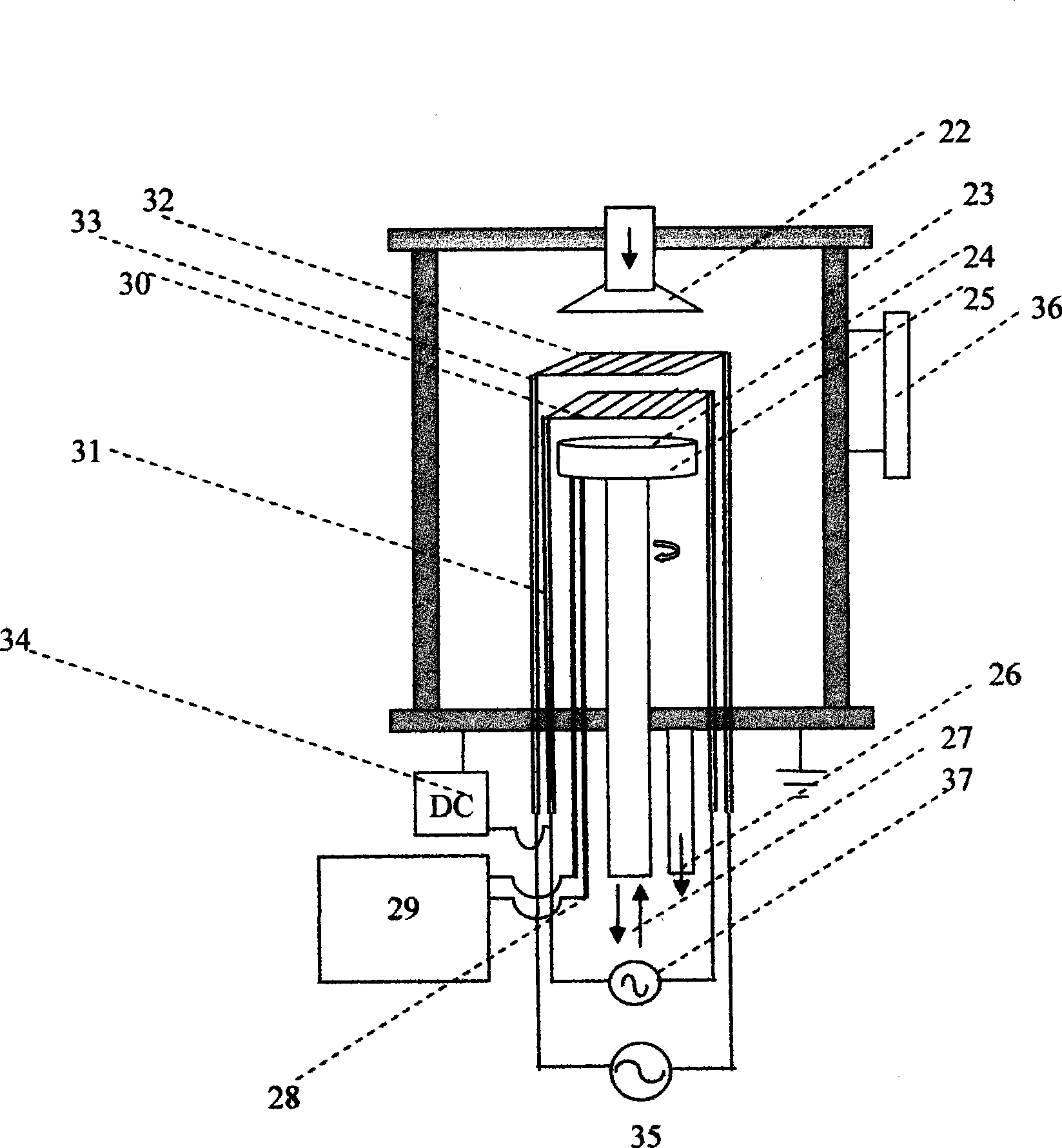

[0062] The specific implementation of each part of the device is as follows:

[0063] The present equipment consists of placing the thermal evaporation device (32) in parallel between the gas diffusion unit (6) (8) (22) and the hot filament (3) (14) (30) in the conventional hot filament plasma equipment, the thermal evaporation device (32) is installed and fixed on several vertical support rods on the base of the vacuum chamber, the connection between the thermal evaporation device (32) and the support rod is fixed with screws, and the thermal evaporation device (32) can move up and down along the vertical support rod to adjust the thermal evaporation device (32) The position on the support rod, the distance from the sample on the substrate can be adjusted. The thermal evaporation device (32) is connected with the outdoor power supply through the terminal on the wall of the vacuum chamber.

[0064] The hot wire source gas activation device (3) (14) (30) is composed of a hot w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com