Metal rod automatic feeding device for heating furnace

An automatic feeding and metal bar technology, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problem that the feeding cannot be controlled by equipment synchronously, and achieve the effect of saving manpower, improving the degree of automation, and ensuring synchronous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

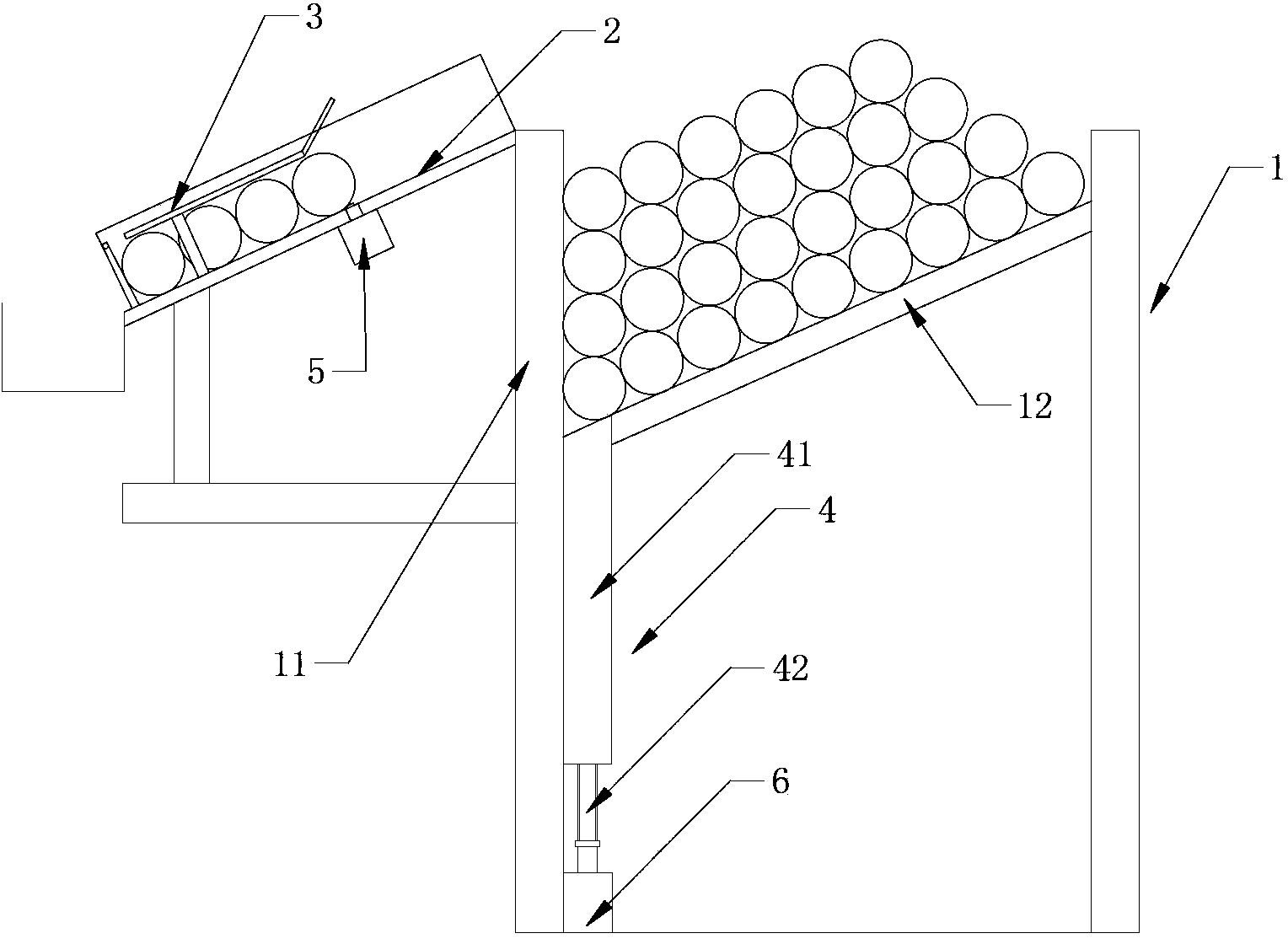

[0019] Such as figure 1 As shown, a metal rod automatic feeding device for a heating furnace includes a material storage box 1 and a material guide trough 2, the material storage box 1 includes a material storage chamber, the material storage chamber includes a bottom plate 12 and side plates, the The bottom plate 12 of the storage chamber is inclined; the material guide chute 2 is installed on the outer wall of the storage chamber and is located on the low side of the inclined bottom plate 12, and the material guide trough 2 is also inclined and the direction of inclination is the same as that of the bottom plate 12 ; The material guide trough 2 is provided with a material retaining device that can block or release the metal rod, and the material retainer device includes a material retaining plate that is movable up and down on the bottom of the material guide trough 2, and the material retaining plate and the cylinder piston rod connection. The cylinder can be used to pull ...

Embodiment 2

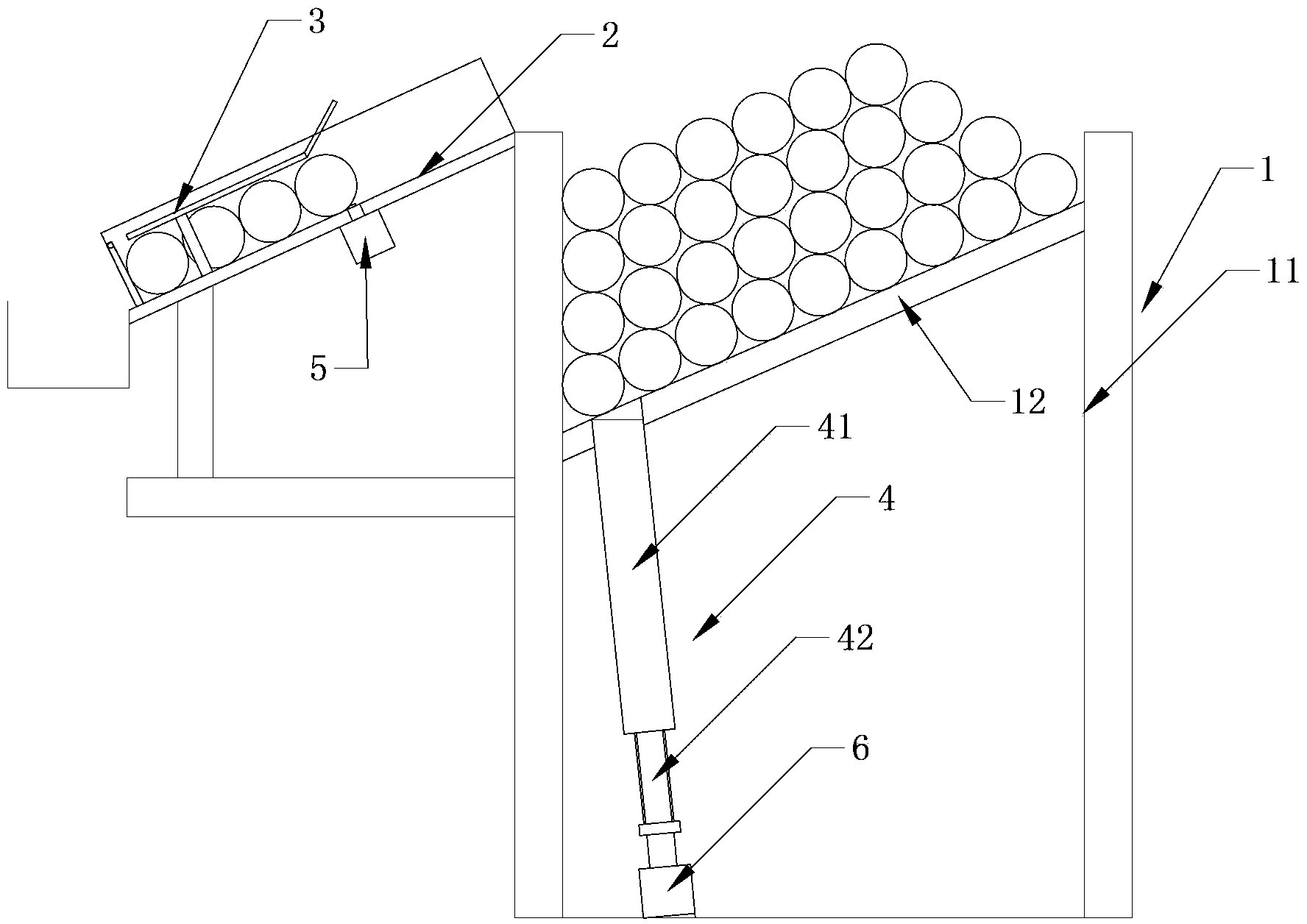

[0024] The structure of this embodiment is the same as that of Embodiment 1, except that the jacking mechanism 4 is different. The jacking mechanism 4 includes a lead screw 42 and a jacking plate 41 threadedly connected with the lead screw 42. The upper end of the jacking plate 41 faces The lower side of the bottom plate 12 is inclined, and the upper end of the lifting plate 41 is set as a horizontal plane or an inclined surface in the same direction as the bottom plate 12. The lead screw 42 is connected with the jacking power device. Like this, the up-and-down movement direction of the jacking plate 41 forms a certain angle with the vertical plane, so the upper end of the jacking plate 41 can be set to an inclined surface or directly set to a horizontal plane, then, when the jacking plate 41 moves upwards, it can still Effectively push the metal rods, and by optimizing the inclination angle of the lifting plate 41, only two metal rods can be lifted at most.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com