Device and method for distributing steel bars

A technology of distribution device and steel bar, applied in the field of steel bar distribution device, can solve the problems of low adaptability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

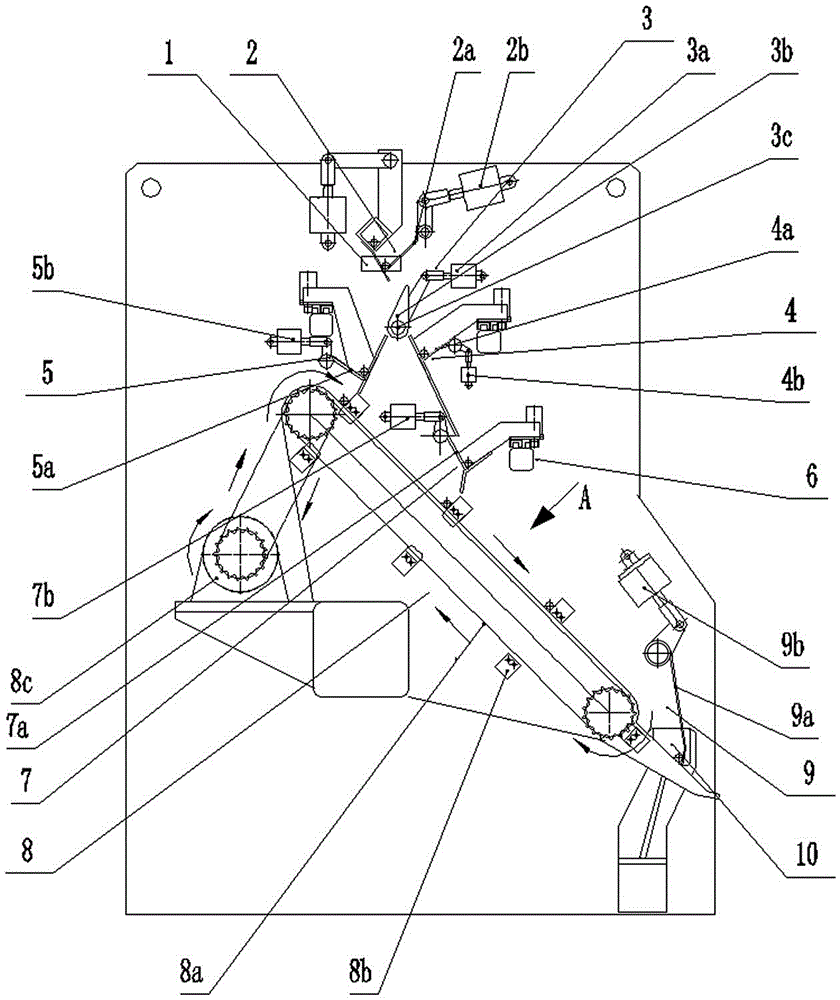

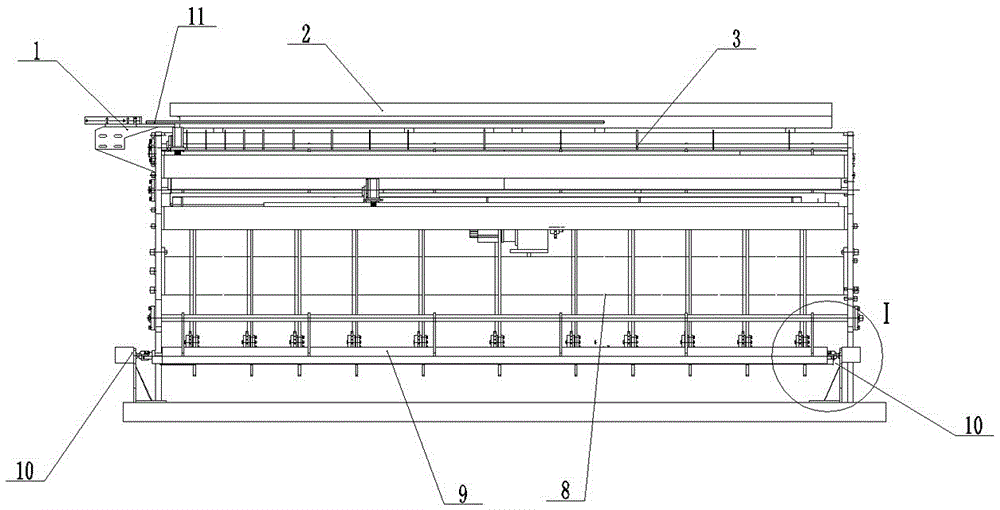

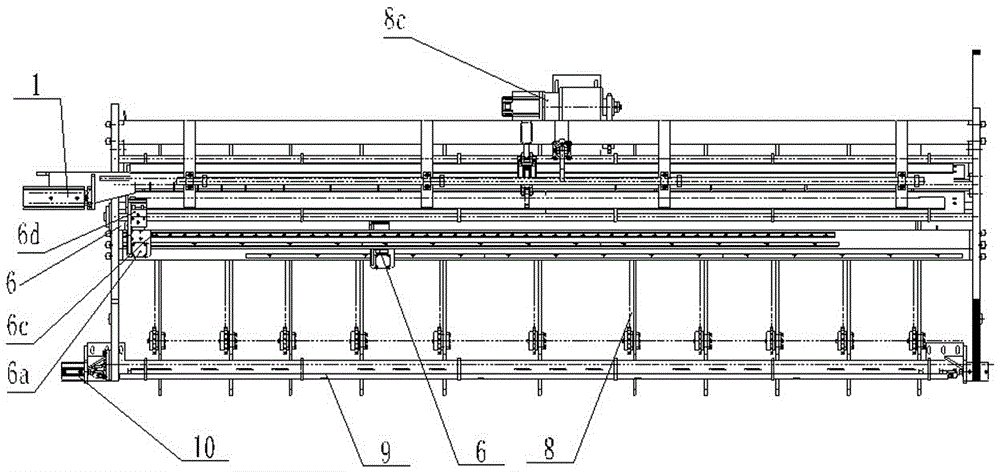

[0042] refer to Figure 1-Figure 3, a steel bar distributing device, including a feed bin 2 for receiving straightened steel bars, a conveying device 8 for transporting the steel bars, and an output bin 9 for outputting the steel bars to the main machine for forming the steel mesh. The material distribution device 3 of the material cylinder 3a, the material distribution plate 3b and the swing shaft 3c, the output end of the material distribution cylinder is connected with the swing shaft 3c, and the rotation of the swing shaft drives the material distribution plate 3b to swing, and the two sides below the material distribution plate 3b The first storage device 4 and the second storage device 5 are respectively arranged on the side, and the third storage device 7 is also arranged below the first storage device, and the first storage device, the second storage device and the third storage device are all configured with The steel bar laterally pushing device 6, the conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com