Method and device for gasifying feedstock

A raw material, gasifier technology, applied in mechanical equipment, gasification process, combustion method, etc., can solve problems such as hindering the total amount of raw materials, low efficiency, inconsistent quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

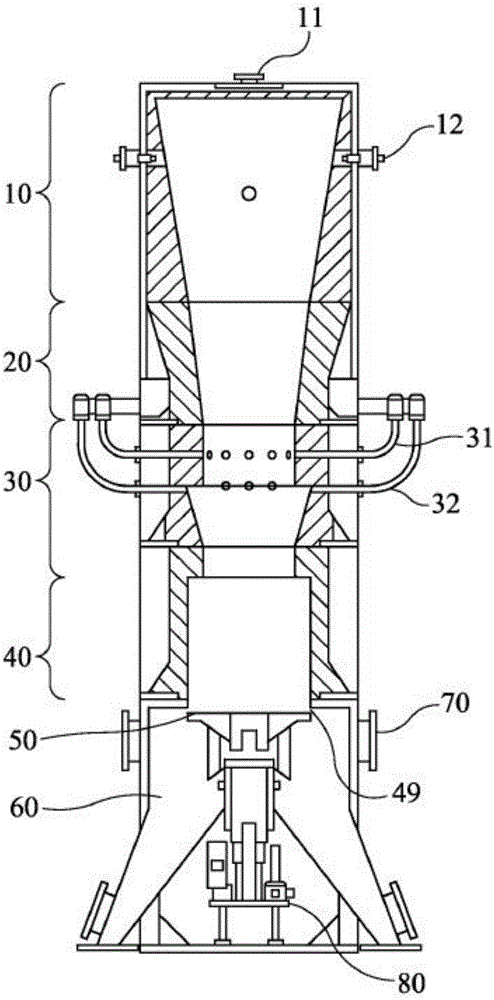

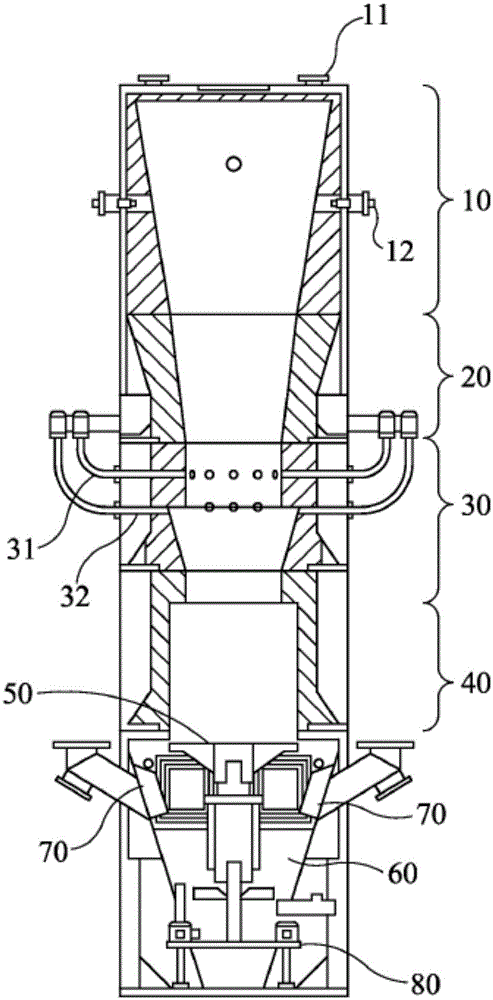

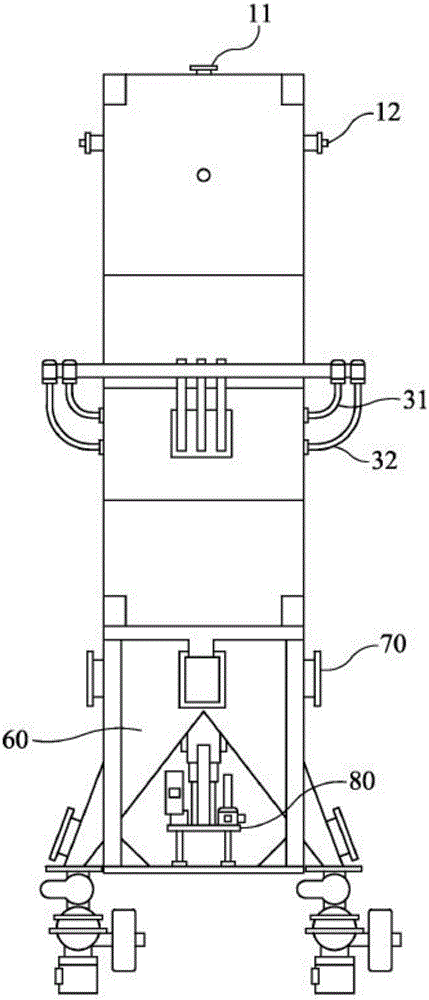

Image

Examples

Embodiment Construction

[0041] definition

[0042] The following defined terms are not limiting or comprehensive, but are provided as a quick reference tool for understanding the present invention. Other defined terms used elsewhere in this document are capitalized. Capitalized terms include all inflections, singular and / or plural forms of the terms employed herein.

[0043] "Bed Oxidant Stream" or "Bed Air" means an oxidant stream that enters a gasifier through an inlet (i.e., a non-flat inlet) that is located in the pyrolysis zone (or can selected drying zone) top.

[0044] "Biochar" means the carbon ash and residue by-products formed when biomass feedstock is gasified.

[0045] "Bypass" means the "gap" between the top of the grate below the gasifier and the opening at the bottom of the reduction zone, also known as the grate pitch.

[0046] By "control system" is meant an operating system comprising multiple control mechanisms and coordinating software for the user / operator to adjust gasifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com