Biomass efficient clean charcoal and gas poly-generation device

A clean carbon and biomass technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of low calorific value of gas, reduced resources, difficult sealing, etc., achieve low tar and other impurities, reduce energy loss, Make full use of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and cannot be interpreted as limiting the protection scope of the application. The above application content makes some non-essential improvements and adjustments to this application.

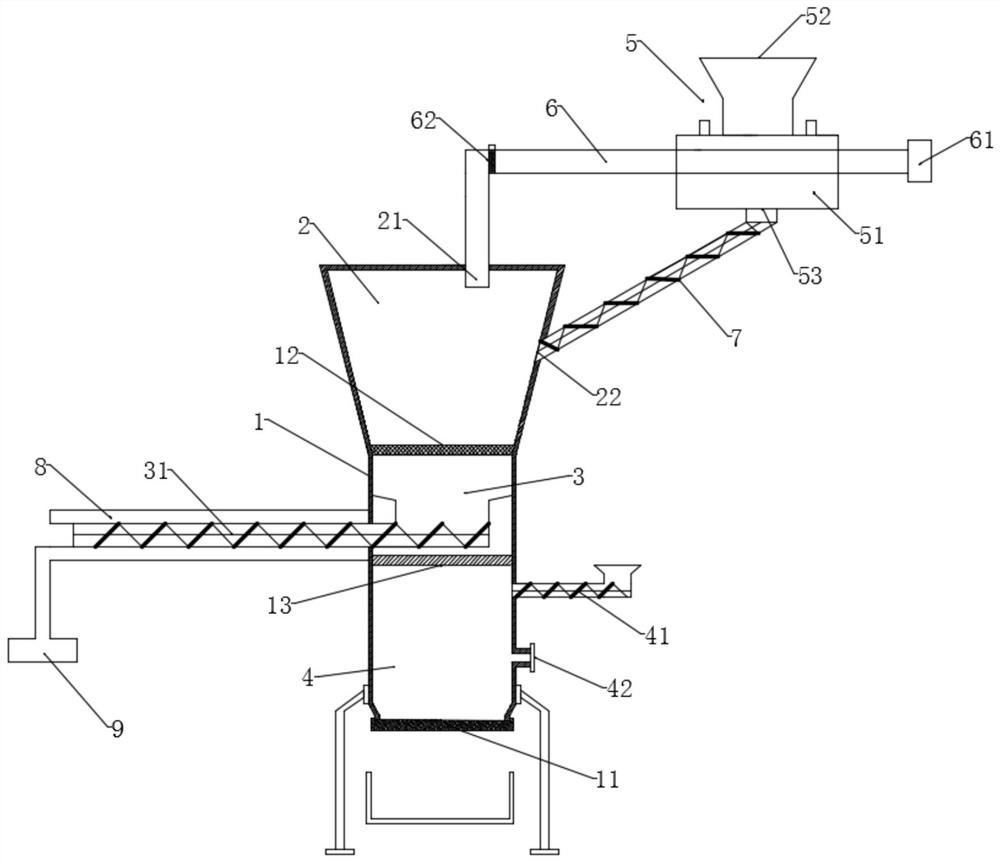

[0016] Such as figure 1 Shown is a polygeneration device for efficiently cleaning biomass and gas, comprising a furnace body 1, the bottom of the furnace body 1 is provided with an ash outlet 11, and the furnace body 1 is provided with a fire grate 12, and the fire grate 12 A heat conducting plate 13 is provided below;

[0017] Wherein, the top of the grate 12 is set as the gasification chamber 2, the carbonization chamber 3 is set between the grate 12 and the heat conduction plate 13, and the combustion chamber 4 is set below the heat conduction plate 13;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com