A gas distribution and ash discharge device for an updraft gasifier

A technology of ash discharge device and gasifier, which is applied in the manufacture of combustible gas and petroleum industry, and can solve the problems of poor convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

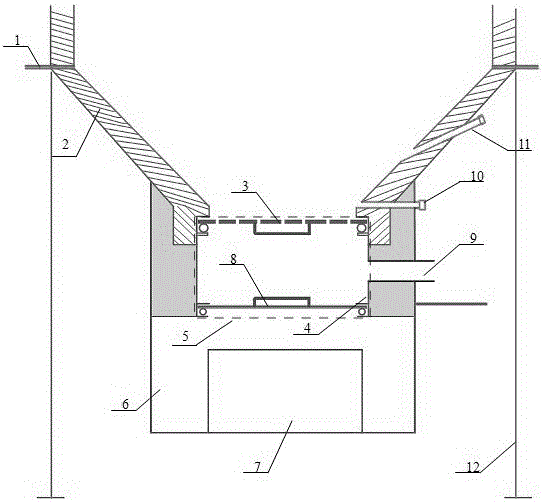

[0017] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 , the gas distribution and ash discharge device of the updraft gasifier described in this embodiment includes enamel 1, gasification bucket 2, gas distribution plate 3, inner cylinder 4, inspection door 5, ash storage box body 6, ash discharge Door 7, ash control plate 8, air intake pipe 9, electronic ignition pipe 10, slag breaking pipe 11, furnace foot 12, wherein the main body of the gasification bucket 2 is funnel-shaped with a large top and a small bottom, and the inclination of the funnel is α, α≤ 60 0 , the top of the main body is provided with enamel 1, and the bottom of enamel 1 is provided with furnace foot 12; The lower part of the gasification bucket 2 is provided with an electronic ignition tube 10, the bottom of the gasification bucket 2 is provided with an ash storage box body 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com