Large-scale biomass briquette fuel fixed bed gasification power generation system

A technology for forming fuel and power generation systems, which is applied to fuel oil systems, combustion engines, and the manufacture of combustible gases. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

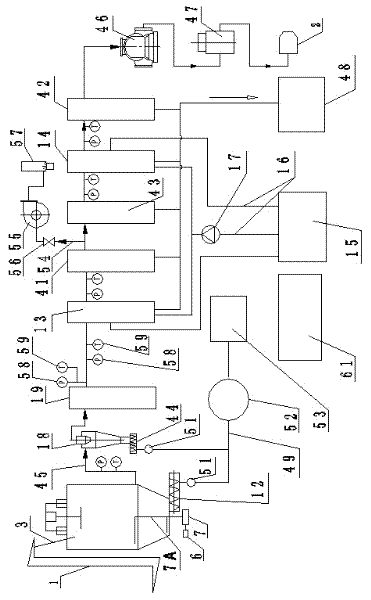

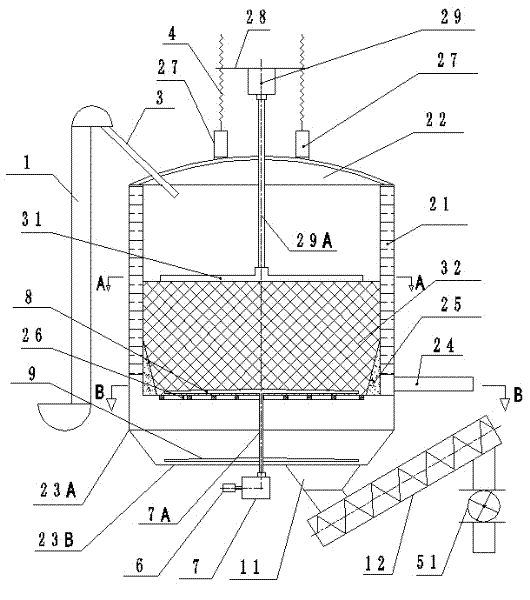

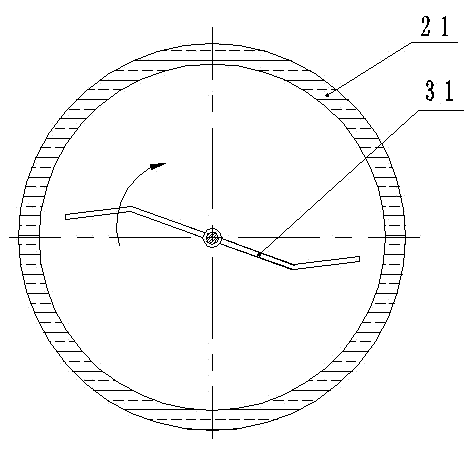

[0030] Such as Figure 1 to Figure 5 shown ( figure 1 The direction indicated by the middle arrow is the flow direction of the medium in the pipeline. image 3 The direction of the middle arrow is the rotation direction of the rake), the large-scale biomass briquette fuel fixed-bed gasification power generation system of the present invention includes a feeding device 1, a down-suction gasifier, a purification system and a gas-fired generator set 2, the down-suction The type gasifier includes a hearth, the hearth includes a cylindrical water interlayer 21, the top of the water interlayer 21 is provided with a top cover 22, the bottom of the water interlayer 21 is connected with an ash bin, and the ash bin includes an ash bin side part 23A and an ash bin bottom. The wall 23B and the side part 23A of the ash bin are provided with an air outlet 24; the joint between the ash bin and the water interlayer 21 is provided with a refractory material 25 to maintain the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com