Biomass gasifier control method

A control method and gasifier technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of low calorific value, harsh working environment, unstable gas production, etc., and achieve strong robustness and improved gas production quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

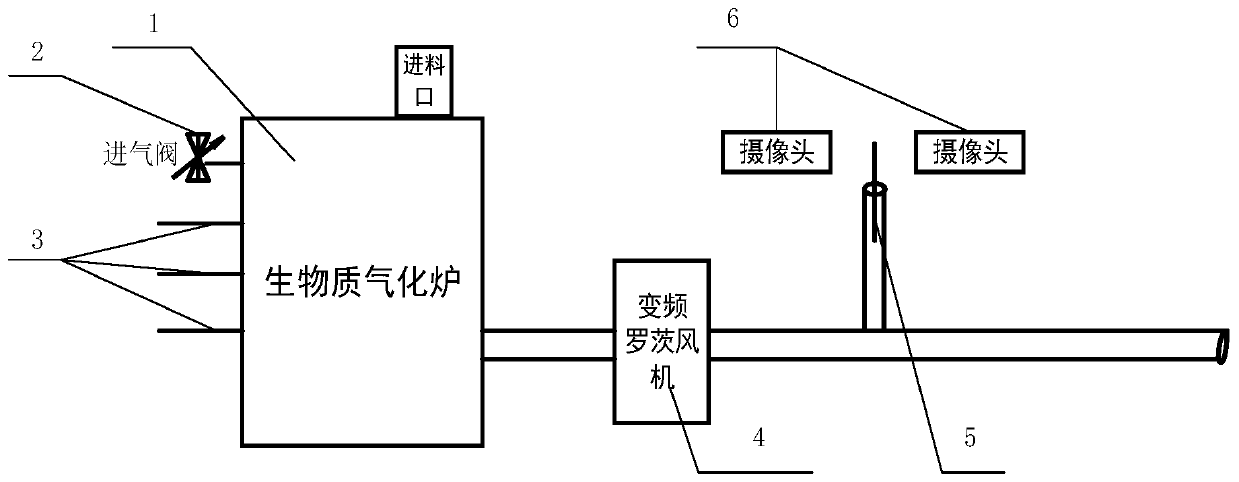

[0013] As shown in the figure, the biomass raw material enters the gasification furnace 1 through the feed port, and contacts with the gasification agent introduced into the furnace through the inlet valve 2. In the gasification furnace, it undergoes complex physical and chemical reactions to generate gas containing carbon monoxide and hydrogen. , methane and other combustible gases and nitrogen, carbon dioxide mixed gas, the mixed gas produced by the frequency conversion Roots blower 4 is extracted from the bottom of the gasifier, after the purification system, most of the mixed gas enters the subsequent gas storage device or other links through the pipeline, less Part of it is burnt at an open flame for the detection of gas calorific value.

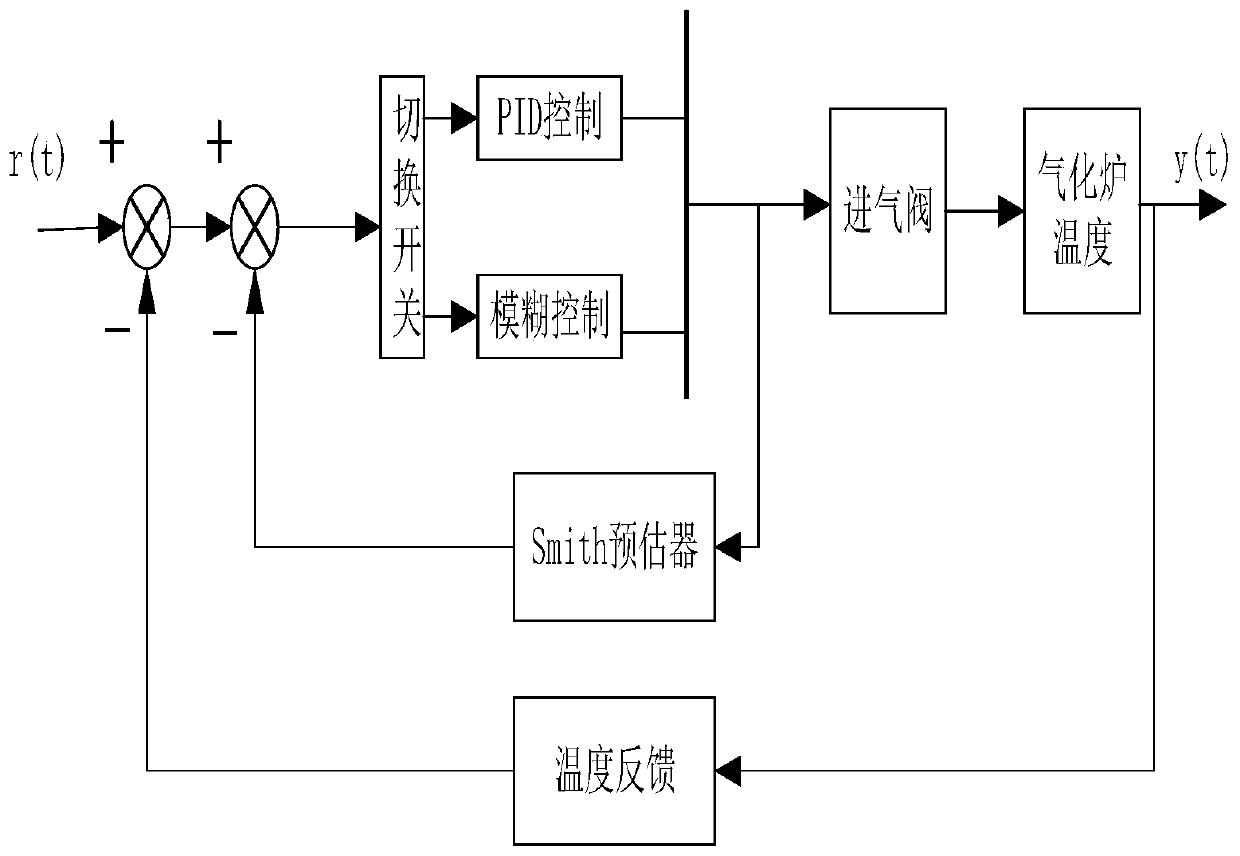

[0014] When controlling the temperature in the furnace, multiple sensors 3 around the furnace transmit the temperature to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com