Biomass downdraft fixed bed gasifier heat supply system

A fixed-bed gasifier and heating system technology, applied in the field of biomass down-suction fixed-bed gasifier heating system, can solve the problems of long gasification time, inapplicability, low gas production, etc., and achieve low equipment investment. , sufficient source, the effect of fuel regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

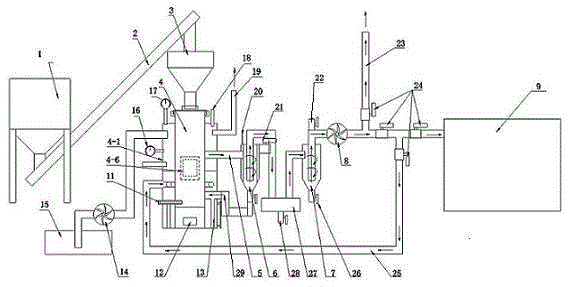

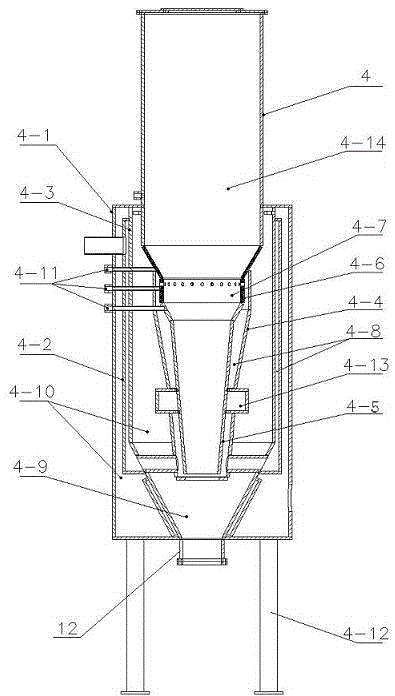

[0013] Embodiments, with reference to the accompanying drawings, a biomass downdraft fixed-bed gasifier heating system includes a primary silo 1, a secondary silo 3, a screw feeder 2, a water pump 14, a Roots variable frequency blower 8 and storage The gas device 9 is characterized in that a downdraft gasification furnace body 4 is installed below the secondary silo 3, and the exhaust pipe 5 of the downdraft gasification furnace body 4 communicates with the waste heat recovery device 6, and the waste heat recovery device 6 The upper exhaust pipe communicates with the air storage tank 27, and the air outlet pipe of the air storage tank 27 communicates with the spiral dust removal and washing device 7. The lower end of 7 is equipped with dust removal and washing valve 26; the upper end of waste heat recovery device 6 is equipped with water level gauge 21; connected; the air storage tank 27 is equipped with an air storage tank exhaust port 28, and a valve is installed on the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com