Charcoal/ash removal system for a downdraft gasifier and associated methods

a gasifier and downdraft technology, applied in the direction of combustible gas chemical modification, combustible gas purification/modification, combustible gas production, etc., can solve the problems of no system currently addressing all of these desirable features, process is not simple extraction and disposal technique,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

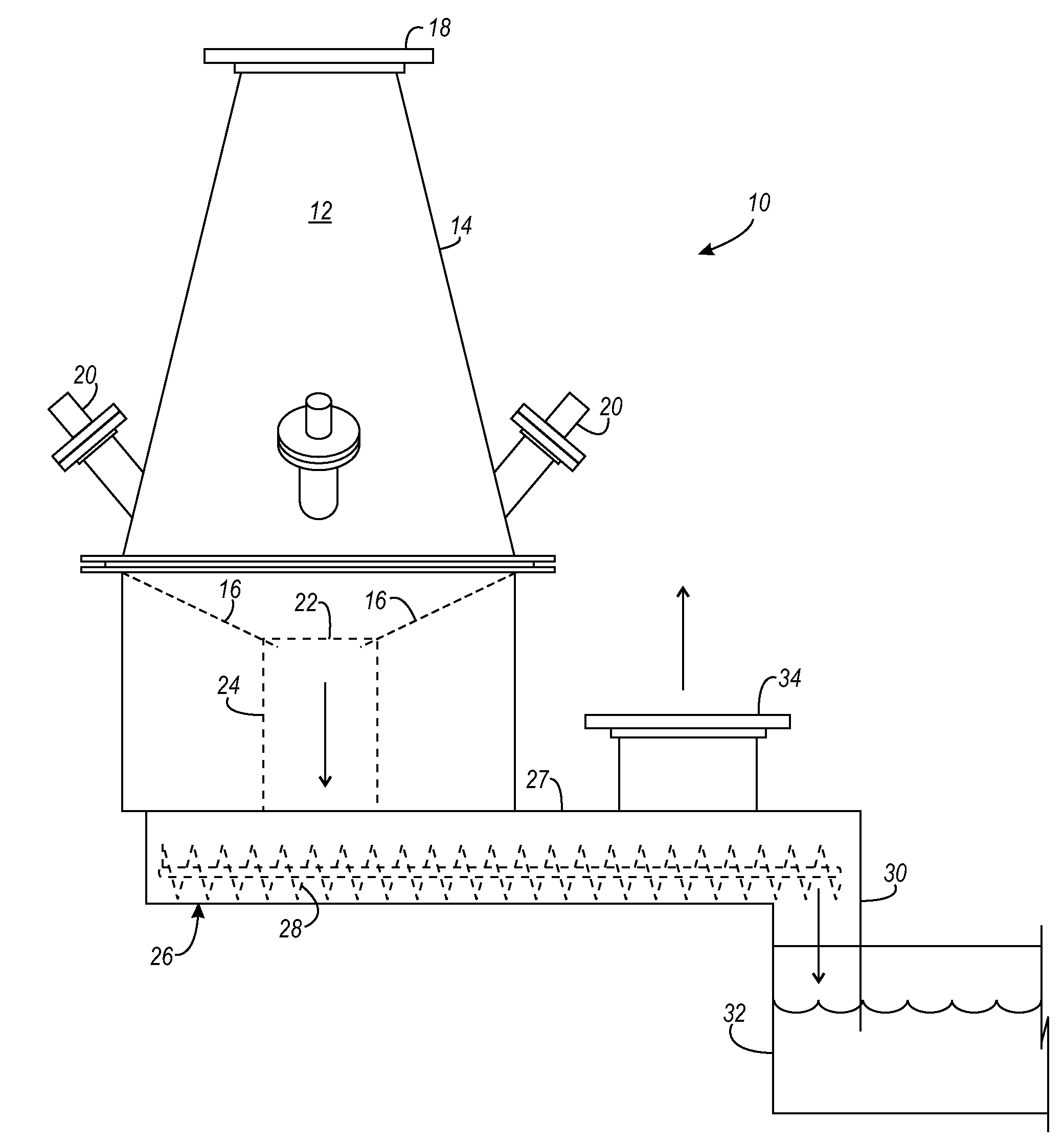

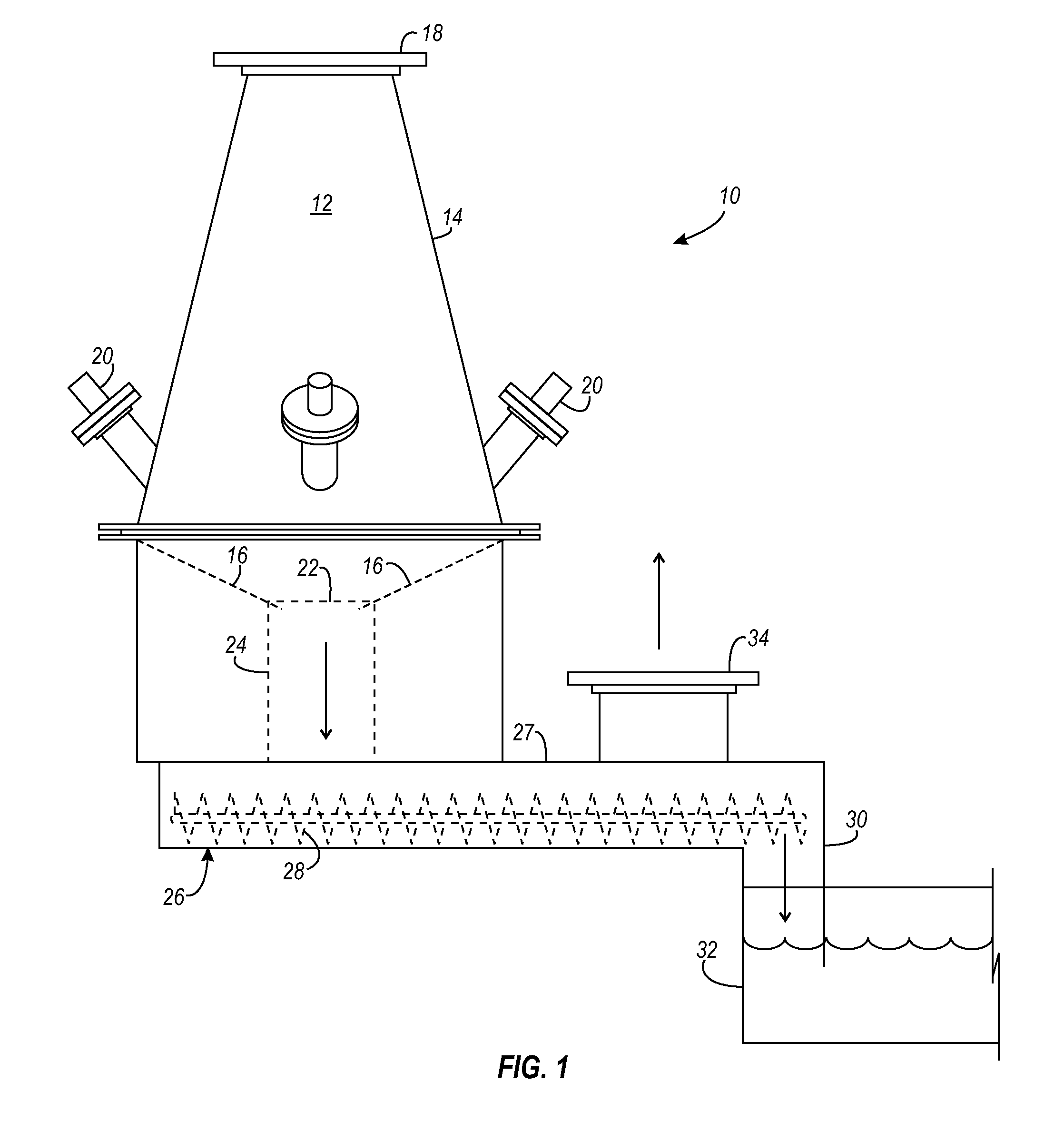

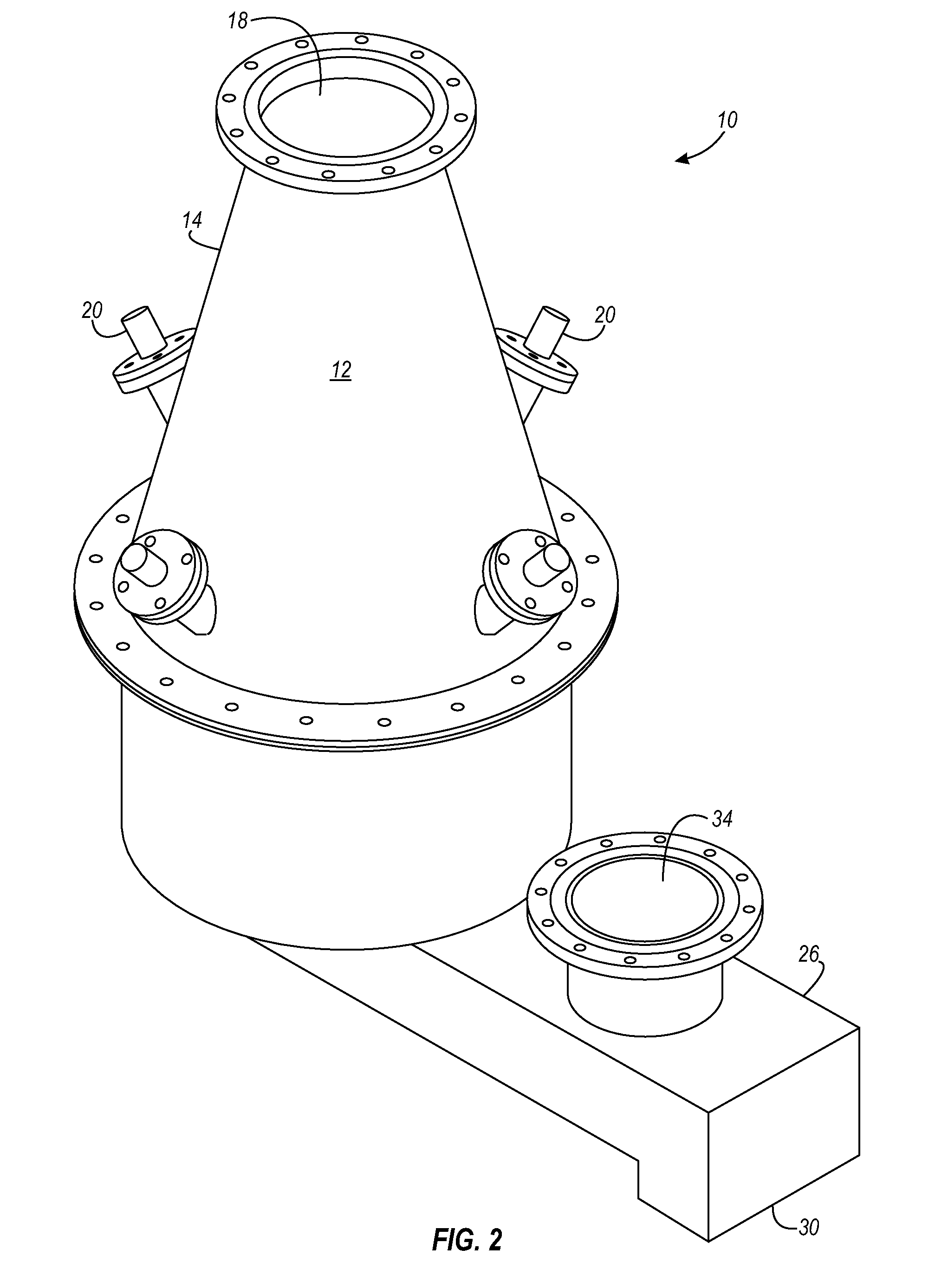

[0017]There is a need for improved techniques for removal of solids from gasifiers, including gas disengagement mechanisms designed to prevent plugging and blinding of gas offtake systems, while simultaneously limiting particulate entrainment in gas produced from the gasifier. It is also desired that such a mechanism also include 1) limited disturbance of the fixed bed, 2) the ability to handle metal objects and ash clinkers, 3) an airtight seal of the gasifier, 4) dust mitigation of the solids discharge, and 5) fire prevention of hot charcoal discharged from the process.

[0018]The present invention provides a simple and effective solution for removal of solids and for gas disengagement from a fixed-bed gasifier. The present invention provides a novel means for removing hot solids from the discharge end of the process, while eliminating plugging and blinding of the exhaust gas manifold and limiting particulate entrainment into the produced gas.

[0019]One example of an apparatus of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com