Method and system capable of improving coal fired boiler low load SCR inlet smoke temperature

A coal-fired boiler, low-load technology, applied in the direction of combustion method, fuel supply adjustment, use of multiple fuel combustion, etc., can solve the problem of limiting low-load operation capacity, large deviation of flue gas temperature at SCR inlet, and affecting SCR System stable operation and other issues, to achieve the effect of increasing flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

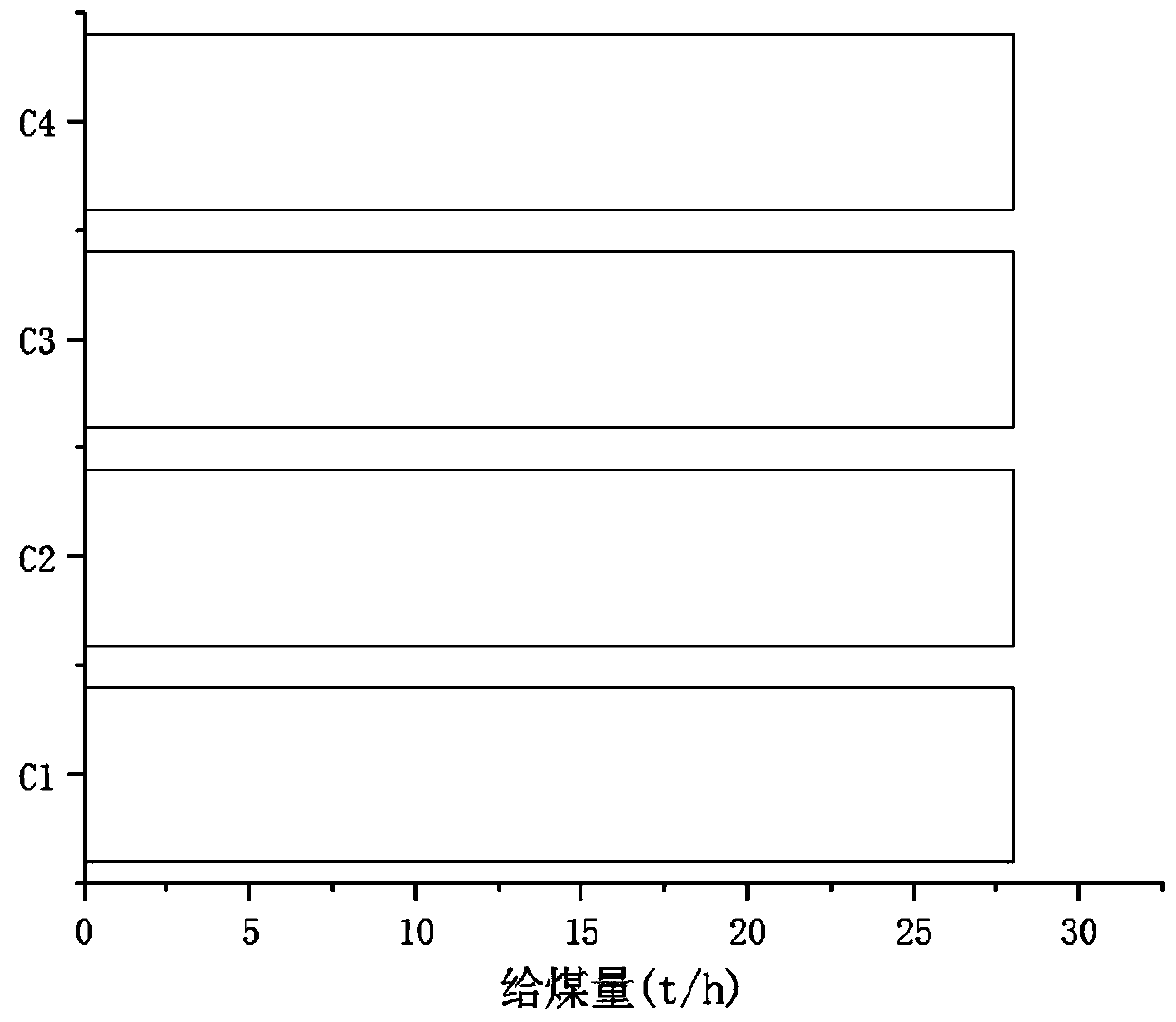

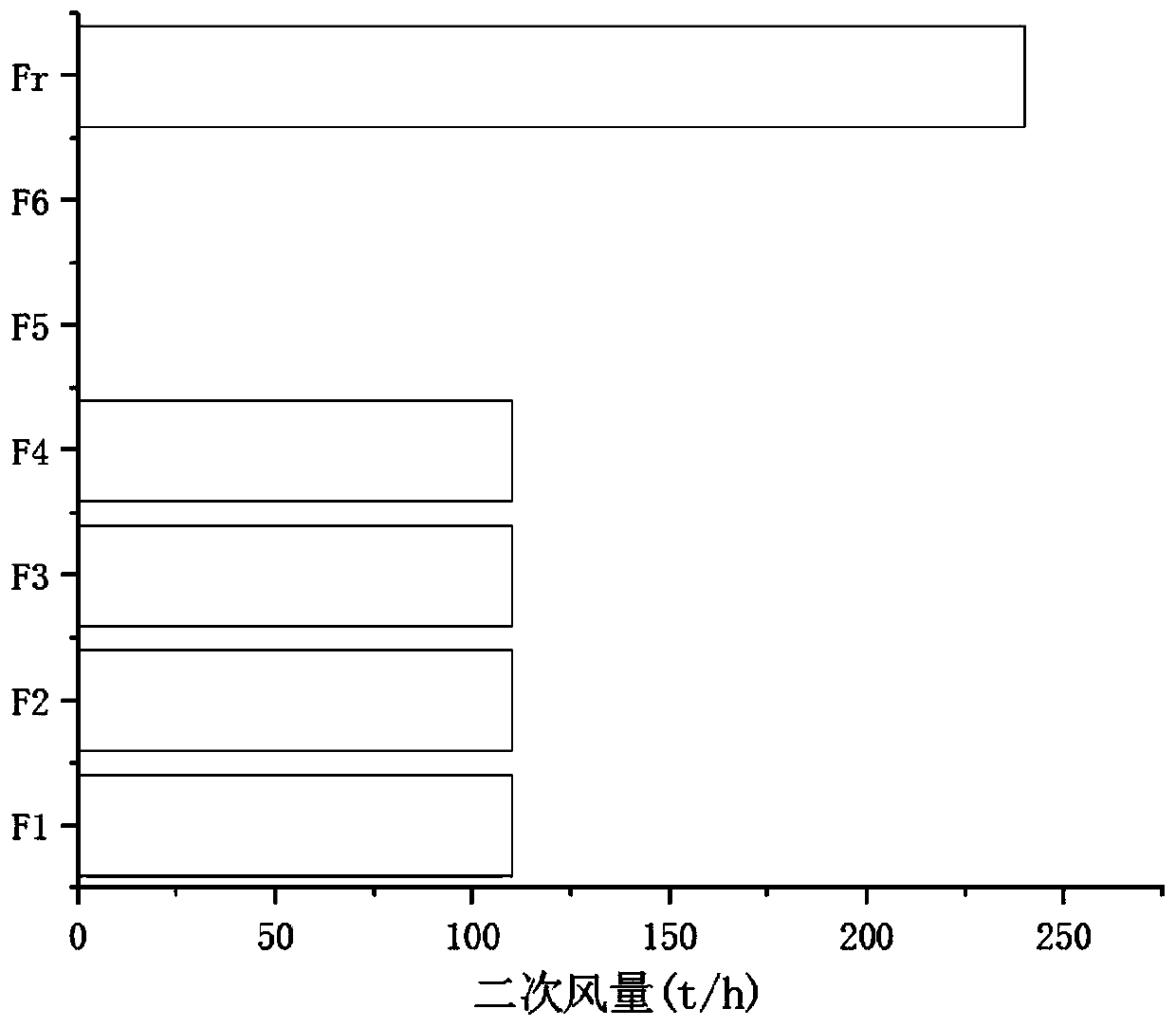

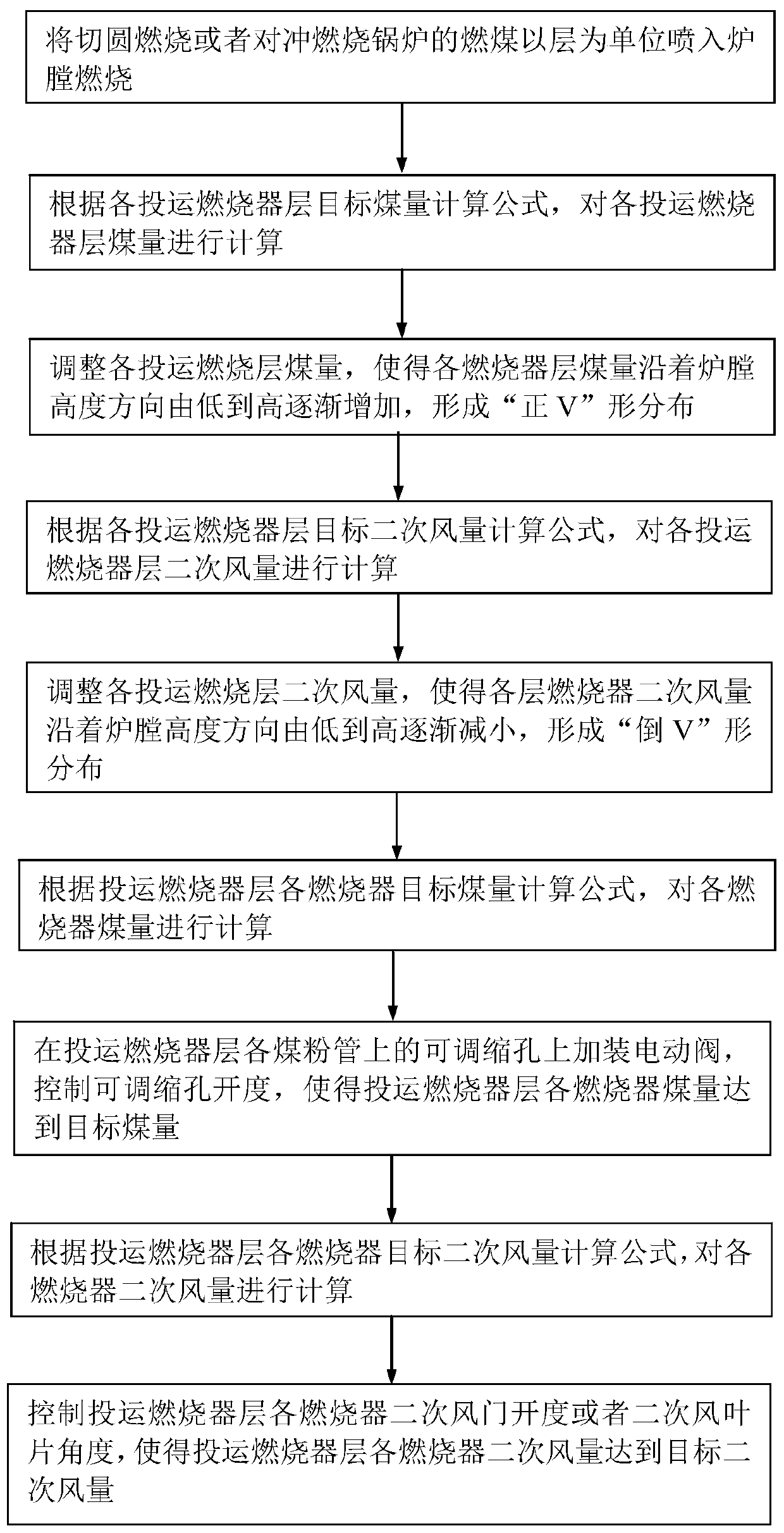

[0045] This embodiment provides a method for increasing the flue gas temperature at the low-load SCR inlet of a coal-fired boiler. Taking the relatively common tangential combustion or opposed combustion boilers in China as the research object, it can reduce the NOx at the furnace outlet as much as possible. X Under the premise of the impact of coal content and pulverized coal burnout rate, by adjusting the distribution of coal volume and secondary air volume of each burner in the commissioned burner layer, the flue gas temperature at the inlet of the low-load SCR can be effectively improved; after adjustment according to the present invention, each layer can be burned The amount of coal in the burner layer gradually increases from low to high along the furnace height direction, forming a "positive V" shape distribution; at the same time, the secondary air volume of each burner layer gradually decreases along the furnace height direction from low to high, forming an "inverted V...

Embodiment 2

[0099] Please refer to the attached Figure 5 , is a schematic diagram of a system for increasing the inlet smoke temperature of a low-load SCR of a coal-fired boiler according to the present invention. The system of the present invention takes the power plant tangential combustion or opposite combustion boiler as the research object, and adjusts the distribution of the coal volume and secondary air volume of each burner in the burner layer. The coal of the boiler is sprayed into the furnace for combustion in units of layers; the coal volume control unit controls the output of each coal feeder and then controls the coal volume of the burners in operation, so that the coal volume of each burner along the height direction of the furnace changes from low to high. Gradually increase to the height, forming a "positive V"-shaped distribution; the coal volume metering unit; the secondary air volume control unit, adjust the secondary air volume of each burner layer in operation, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com