Combustion device of multifunction tangential firing pulverized coal boiler and control method thereof

A tangential combustion, pulverized coal boiler technology, applied in the control of the combustion device of the multifunctional tangential combustion pulverized coal boiler, and the field of the combustion device of the multifunctional tangential combustion pulverized coal boiler, can solve the problem that the tangential circular combustion pulverized coal combustion equipment cannot meet the Large-scale power station boilers cannot take into account the problems of low nitrogen combustion effect and combustion efficiency, poor adaptability of coal types, etc., to achieve the effects of simple construction, high temperature corrosion elimination, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The combustion device and control method of the multifunctional tangentially fired pulverized coal boiler of the present invention will be further described through specific examples below.

[0027] (1) Combustion device of multifunctional tangentially fired pulverized coal boiler

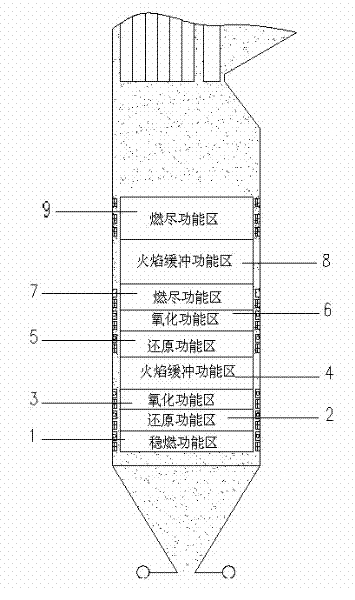

[0028] The layout of the vertical space in the furnace from bottom to top is the stable combustion functional area 1, the reduction functional area 2, the oxidation functional area 3, the flame buffer functional area 4, the reduction functional area 5, the oxidation functional area 6, and the burnout functional area 7 , flame buffer functional area 8 and burnout functional area 9 nine functional areas (see figure 1 ).

[0029] Taking the 300MW unit as an example, the specific division of each functional area is as follows:

[0030] From the inflection point of the cold slag in the furnace, the height of the stable combustion functional area 1 along the furnace is 6-8 meters, the height of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com