Tangential pulverized coal fired boiler and coal-fired power generation system

A technology of pulverized coal combustion and four-corner tangent, which is applied in the combustion of block fuel and powder fuel, the combustion of liquid fuel and powder fuel, the combustion of gaseous fuel and powder fuel, etc. To meet the needs of environmental protection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

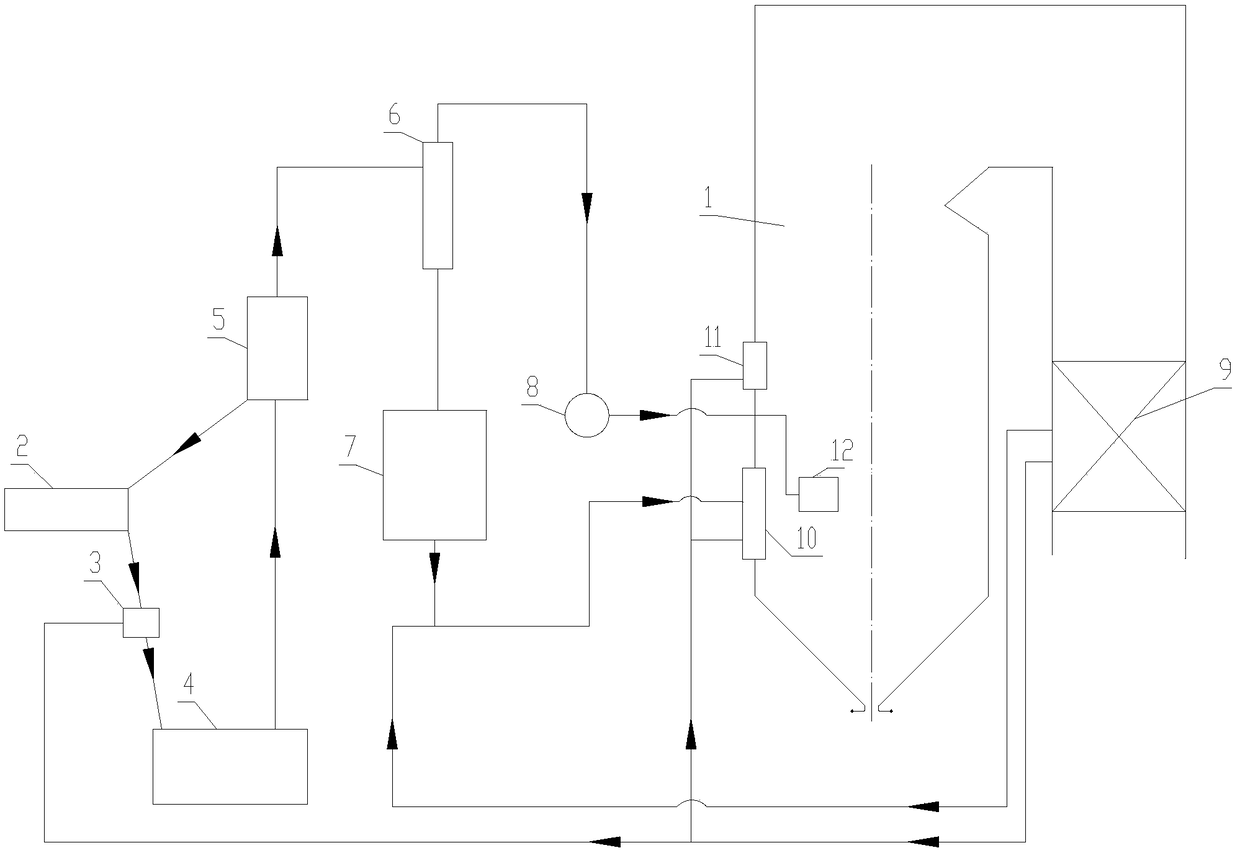

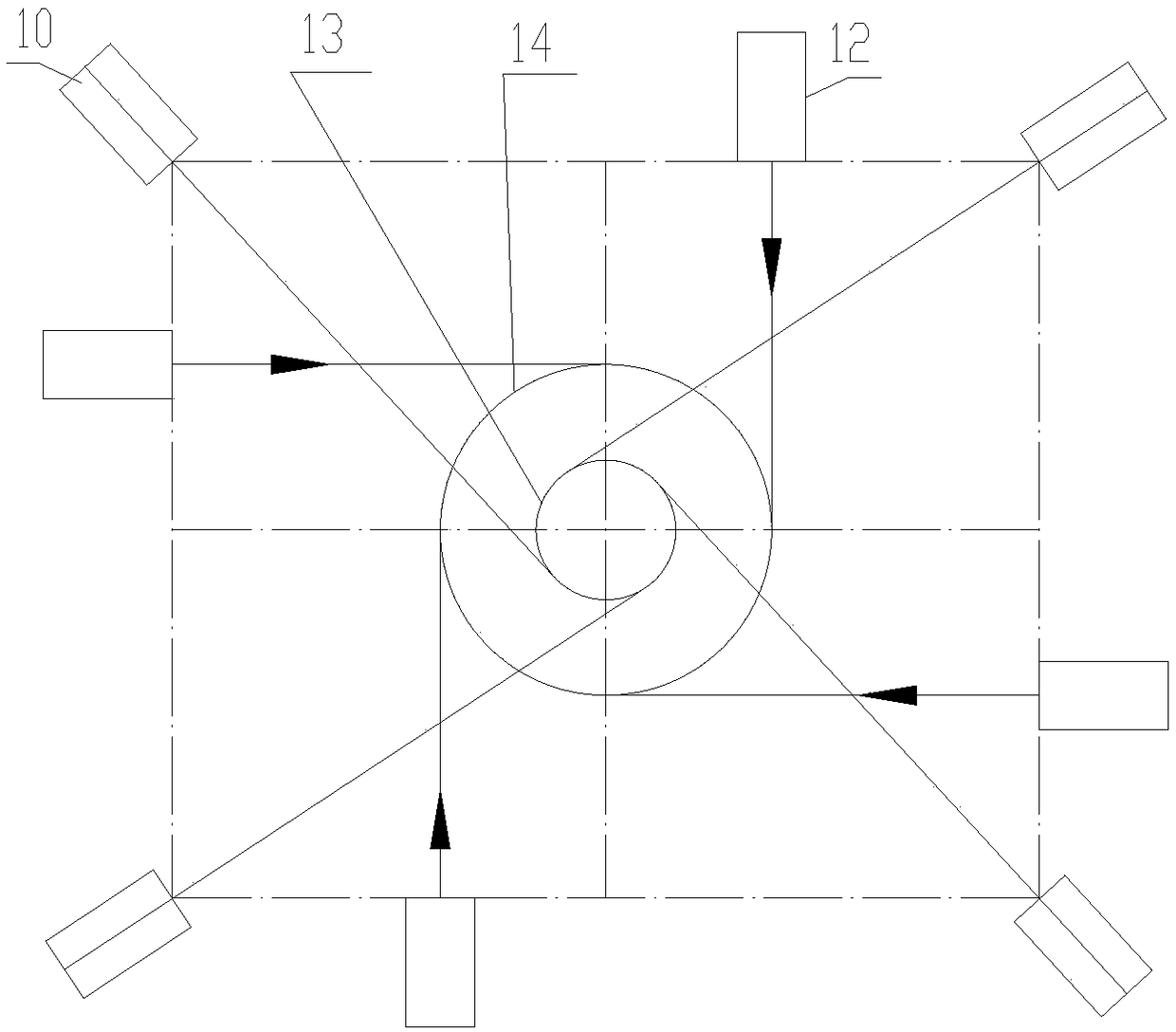

[0027] Such as figure 1 , figure 2 As shown, take a four-corner tangential combustion boiler with an intermediate storage bin-type steel ball mill hot air pulverization system as an example (the system equipment involved in this example is only the main equipment in the entire system, and is not listed. all devices).

[0028] The pulverized coal enters the drying pipe 3 from the coal feeder 2, mixes with the hot air coming out of the preheater 9 and enters the drying pipe 3, and then enters the coal mill 4, and the air powder coming out of the drying pipe 3 passes through the coal mill 4 and then enters the coarse powder Separator 5, unqualified coal powder returns to coal feeder 2, qualified coal powder enters fine powder separator 6, after passing through fine powder separator 6, qualified coal powder enters coal powder bin 7, under the action of other equipment The hot air from the preheater 9 carries the pulverized coal from the pulverized coal bin 7 into the corner bur...

Embodiment 2

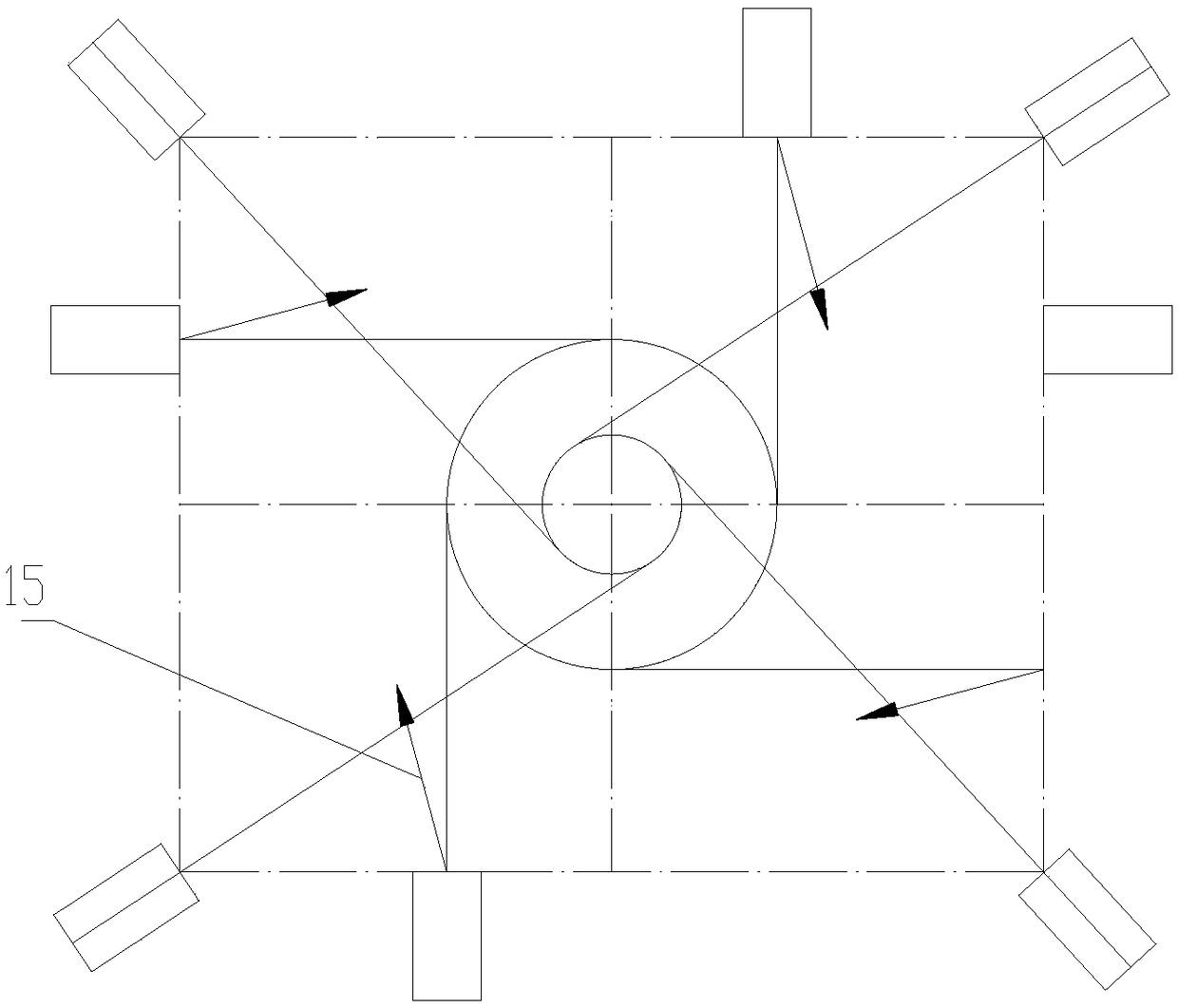

[0031] Such as figure 2 , Figure 4 As shown, on the basis of the first embodiment, the four walls of the furnace 1 are provided with two-layer exhaust gas nozzles in the vertical direction, including the first layer of wall-type exhaust nozzles 12-1 and the second layer of wall-type exhaust nozzles. Air spout 12-2.

Embodiment 3

[0033] Such as figure 2 , Figure 5 As shown, on the basis of the second embodiment, the corner-type exhaust gas nozzles 16 arranged at the four diagonal corners of the furnace 1 are further added. After the exhaust gas enters the furnace, it forms a coupled combustion of angular tangential combustion and wall tangential combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com