Operation evaluation method for additional inlet air of tangential firing tilting nozzles

A technology of swinging nozzles and tangential combustion, which is applied in the direction of controlling combustion, combustion equipment, lighting and heating equipment, etc., and can solve problems such as excessive gaps, reduced volume of organized air distribution, and reduced nozzle wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

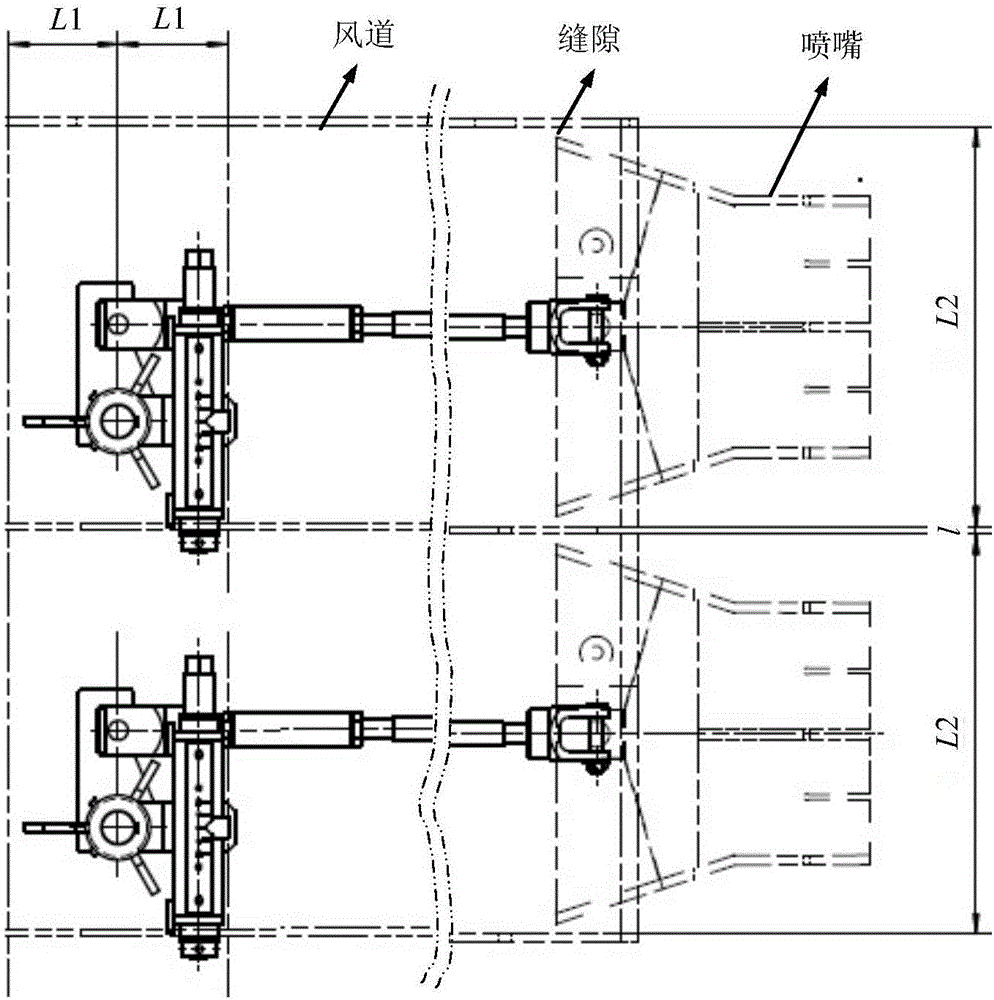

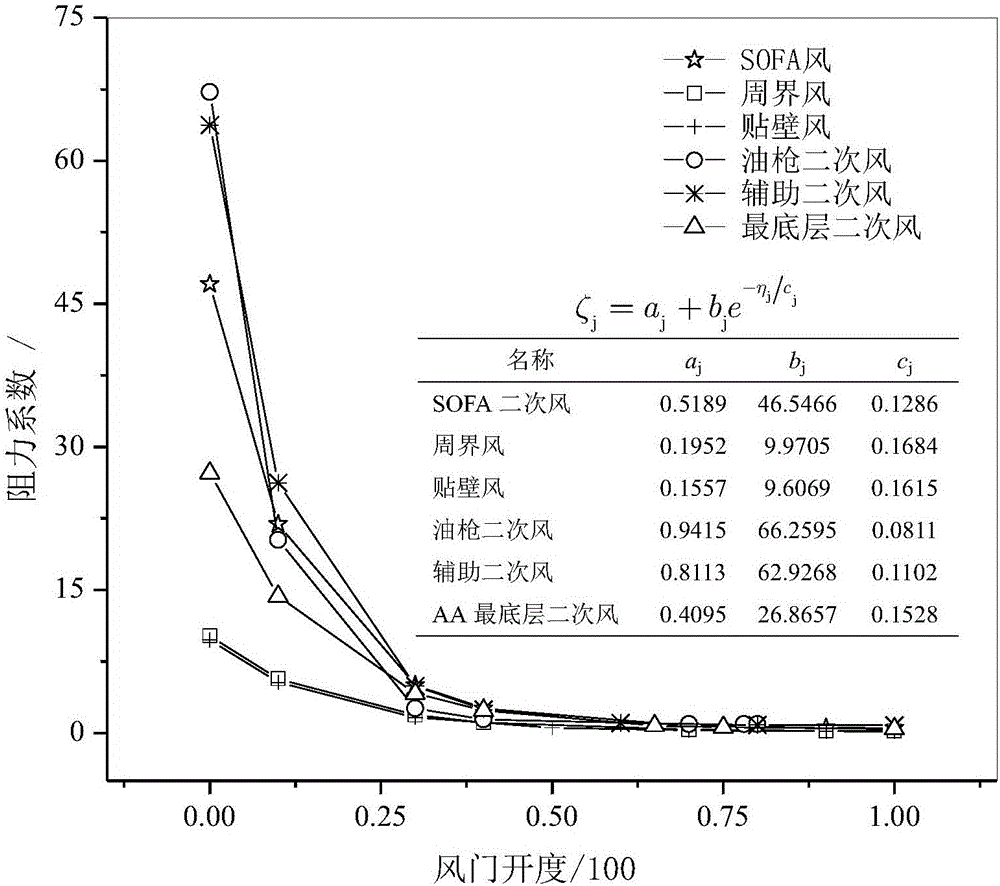

[0098] The implementation object is a subcritical, one-time reheating, single furnace, controlled circulation drum furnace, which adopts tangential combustion low NOx swing nozzle, figure 1 Indicates the swing nozzle and the actuator; the boiler is equipped with 5 sets of RP923 medium-speed coal mills, and each set of pulverizing system supplies powder to 4 burners on the same floor. The furnace has 5 layers of coal powder nozzles, which are recorded as A, B, C, D, E, among them, there is a plasma igniter in the pulverized coal nozzle of layer A; there are 19 layers of air nozzles, 4 in each layer, and a total of 76 air nozzles. The 19 layers of air nozzles are: ①4SOFA Nozzles, a total of 4 layers, namely SOFA1, SOFA2, SOFA3 and SOFA4; ②Auxiliary secondary air nozzle: a total of 3 layers, respectively CD, DE and EE layer secondary air; ③Oil gun secondary air nozzle: a total of 2 layers , which are the secondary air of oil guns in layers AB and BC; ④Perimeter air nozzles of pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com