Tangential firing system under air staged combustion technology

A combustion technology and tangential combustion technology, applied in the field of tangential combustion systems, can solve the problems of high temperature corrosion, easy slagging of water walls, etc. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

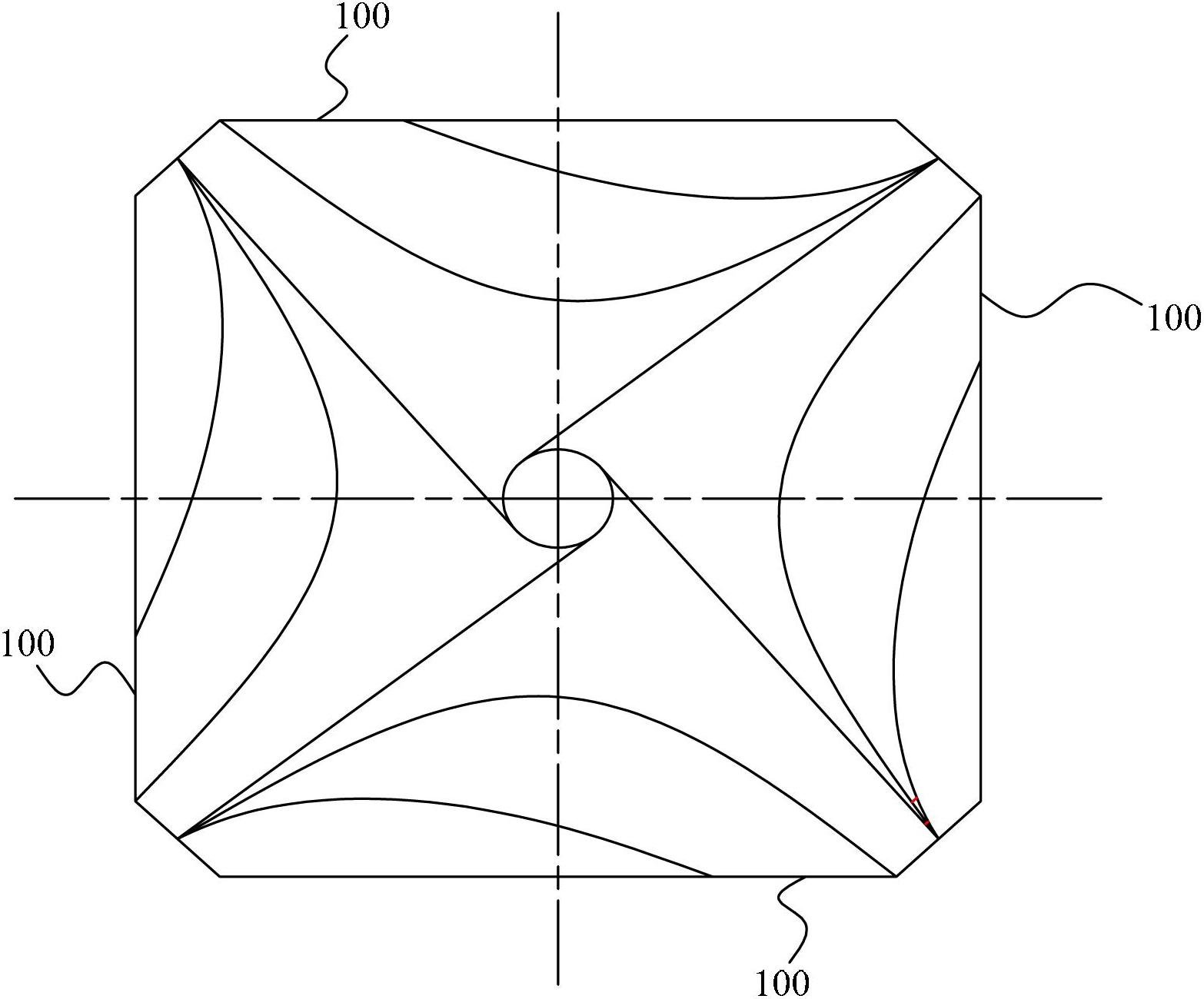

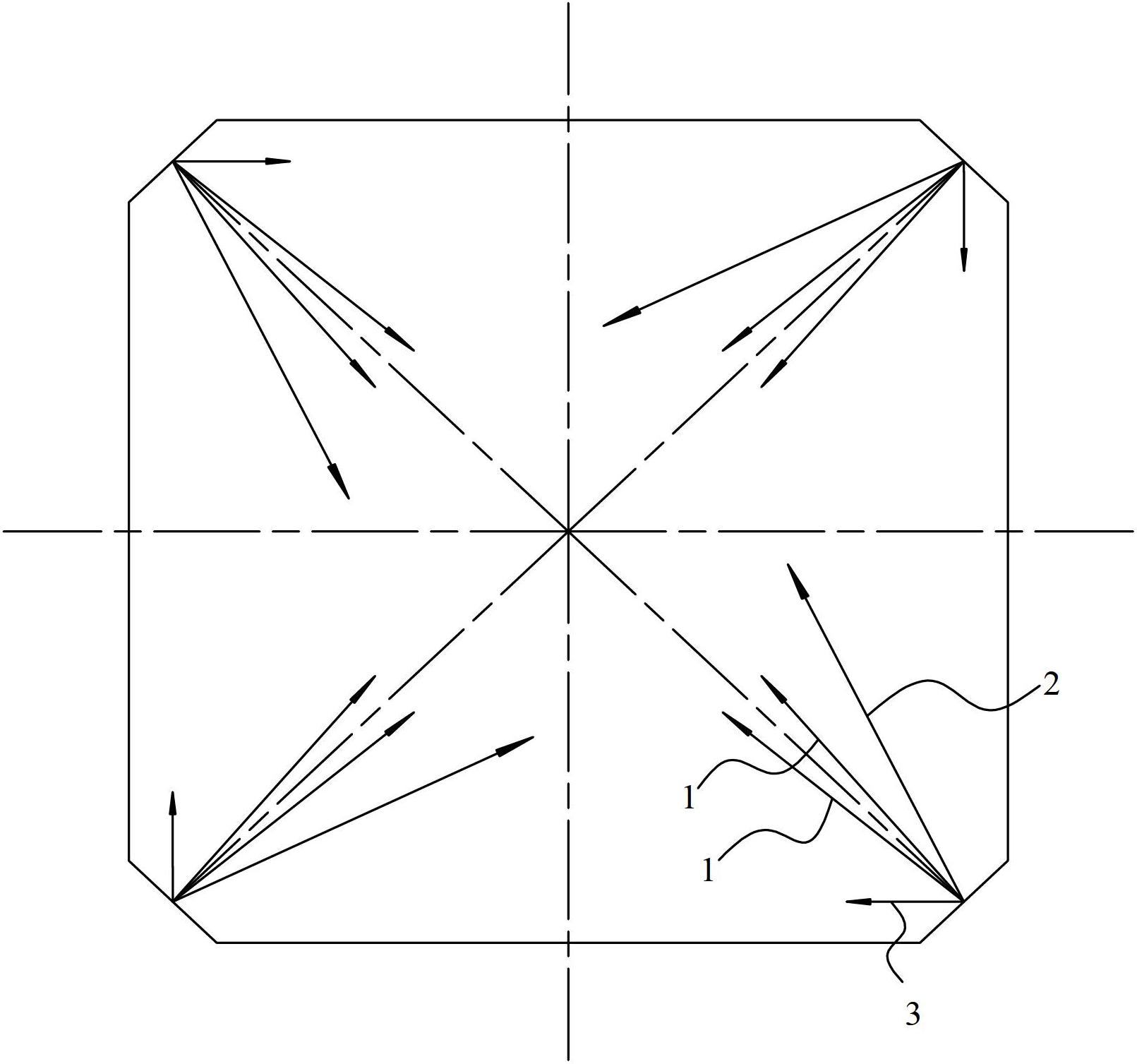

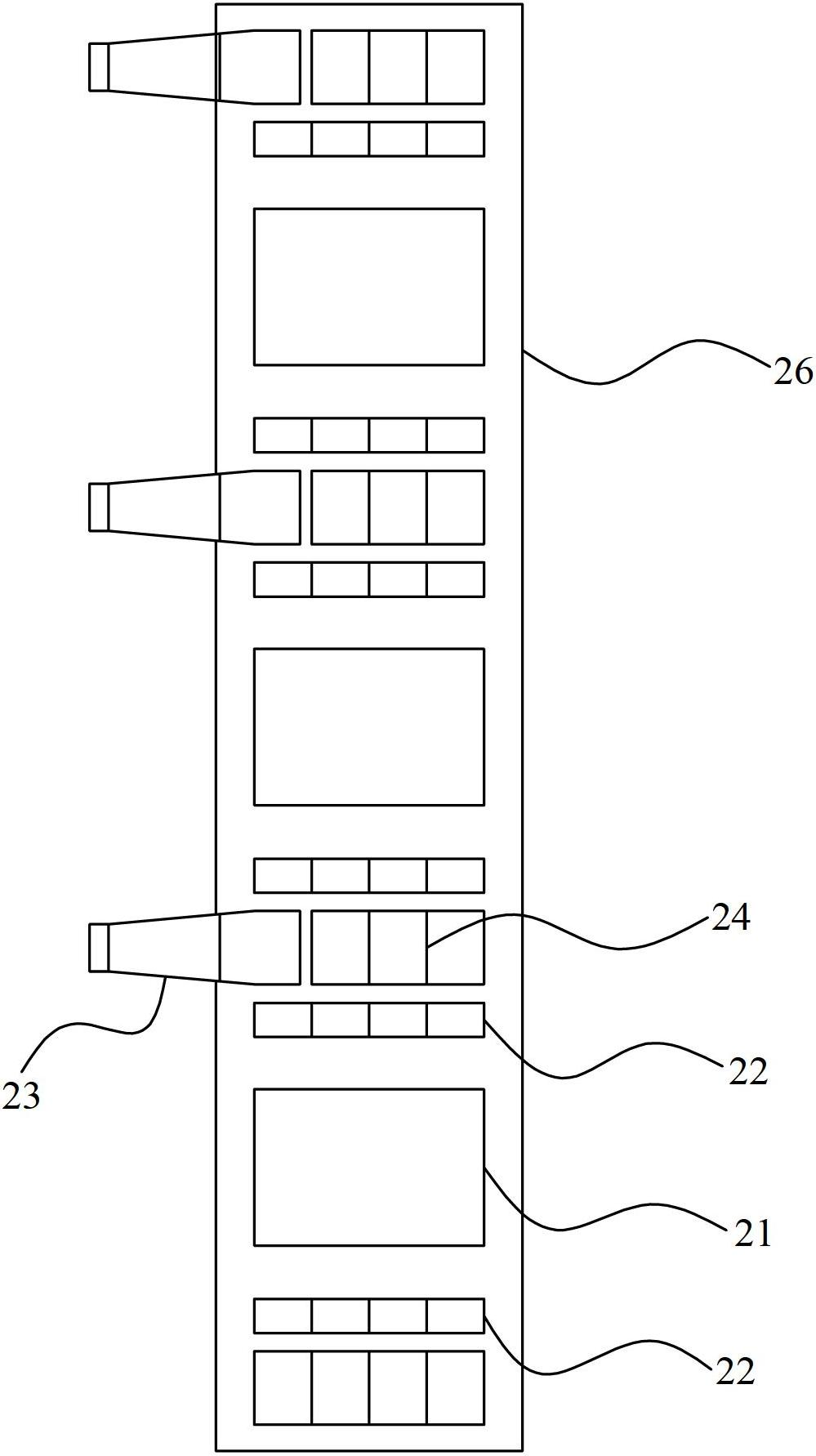

[0028] Below to figure 2 , image 3 , Figure 5 , Figure 6 This embodiment will be described. figure 2 Shown is the airflow injected into the furnace by the combustion system and its direction. The mixed airflow 1 of primary air and pulverized coal is sprayed into the furnace along the direction of the diagonal of the furnace section or at a small angle to the diagonal, and the diagonal primary air and mixed airflow of pulverized coal are opposed to form a smaller tangent circle; offset The cyclone 2 forms a certain angle with the primary air and pulverized coal mixed airflow 1. In one embodiment, the angle is between 10° and 25°, and the offset cyclone air volume is about 10% to 70% of the total air volume entering the furnace . The offset cyclone 2 at the four corners forms a larger tangent circle. On the one hand, it can make the flow field of the entire boiler burn in a tangent circle. Prevent pulverized coal air flow from scouring the water wall; flanging air 3 i...

Embodiment 2

[0032] Below to figure 2 , Figure 4 , Figure 5 , Figure 6 This embodiment will be described. figure 2 The air flow injected into the furnace and its direction for the combustion system. The mixed airflow 1 of primary air and pulverized coal is sprayed into the furnace along the direction of the diagonal of the furnace section or at a small angle to the diagonal, and the diagonal primary air and mixed airflow of pulverized coal are opposed, or form a smaller tangential circle; Set the cyclone 2 to form a certain angle with the primary air and pulverized coal mixed airflow 1, the angle is between 10° and 25°, and the air volume is about 10% to 70% of the total air volume entering the furnace. The offset whirlwind at the four corners forms a larger tangential circle. On the one hand, it can make the flow field of the entire boiler burn in a tangential circle. The pulverized coal airflow scours the water wall; the flanging air 3 is blown into the furnace in the opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com