Method for comprehensively treating phosphorus-containing oolitic hematite and red mud

A technology for comprehensive treatment of oolitic hematite, which is applied in the field of comprehensive treatment of phosphorus-containing oolitic hematite and red mud, can solve the construction and maintenance costs of multiple storage yards, occupy large land and farmland, and waste metal resources, etc. Problems, to achieve great practical significance and social benefits, high product output value, high removal rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

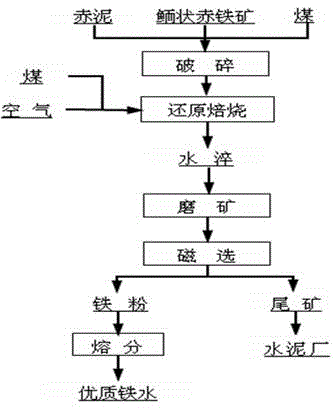

Image

Examples

Embodiment 1

[0049] Ore blending: oolitic hematite (TFe 43%, P 0.9%, Al 2 o 3 7%, SiO 2 22%) 48 parts, red mud (TFe 24%, CaO 14%, Al 2 o 3 13%, SiO 2 9%, Na 4%) 30 parts, bituminous coal 22 parts, mixed and broken to less than 5mm accounted for 96%,

[0050] Roasting: Metallized reduction roasting of crushed materials, the temperature is controlled at 1000°C, CO / CO in the flue gas in the furnace 2 =3.8, the residence time is 2h, the output calcined sand is cooled to 500°C by the heat exchange cooling cylinder, and then water quenched.

[0051] Ball milling and magnetic separation: Water-quenched calcined sand ball milling to less than 0.074mm accounts for 94%, after ball milling, the slurry is adjusted to a pulp concentration of 20%, and magnetic separation is performed at 1500 Oersted to obtain concentrate-like sponge iron powder (TFe 90%, P 0.13 %, Al 2 o 3 1.8%, SiO 2 3.0%), of which the iron selection rate was 92%, and the phosphorus removal rate was 90%.

[0052] Melti...

Embodiment 2

[0054] Ore blending: oolitic hematite (TFe 43%, P 0.9%, Al 2 o 3 7%, SiO 2 22%) 64 parts, red mud (TFe 24%, CaO 14%, Al 2 o 3 13%, SiO 2 9%, Na 4%) 16 parts, 20 parts of anthracite, mixed and broken to less than 5mm accounted for 95%,

[0055] Roasting: Metallized reduction roasting of crushed materials, controlled temperature 1150°C, CO / CO in the flue gas in the furnace 2 =4.0, the residence time is 0.5h, and the output calcined sand is cooled to 600°C by the heat exchange cooling cylinder and then water quenched.

[0056] Ball milling and magnetic separation: water-quenched calcined sand ball milling to less than 0.074mm accounts for 95%, after ball milling, the slurry is adjusted to a pulp concentration of 20%, and magnetic separation is performed at 1000 Oersted to obtain concentrate-like sponge iron powder (TFe 93%, P 0.14 %, Al 2 o 3 1.3%, SiO 2 2.8%), of which the iron selection rate was 93%, and the phosphorus removal rate was 91%.

[0057] Melting: Spo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com