Optimization arrangement mode of high-temperature heating surface

A heating surface and high temperature technology, which is applied in the field of optimized layout of high temperature heating surfaces, can solve problems affecting the clean and efficient combustion of pulverized coal, and achieve the effects of improving safety and reliability, reducing wall temperature deviation, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

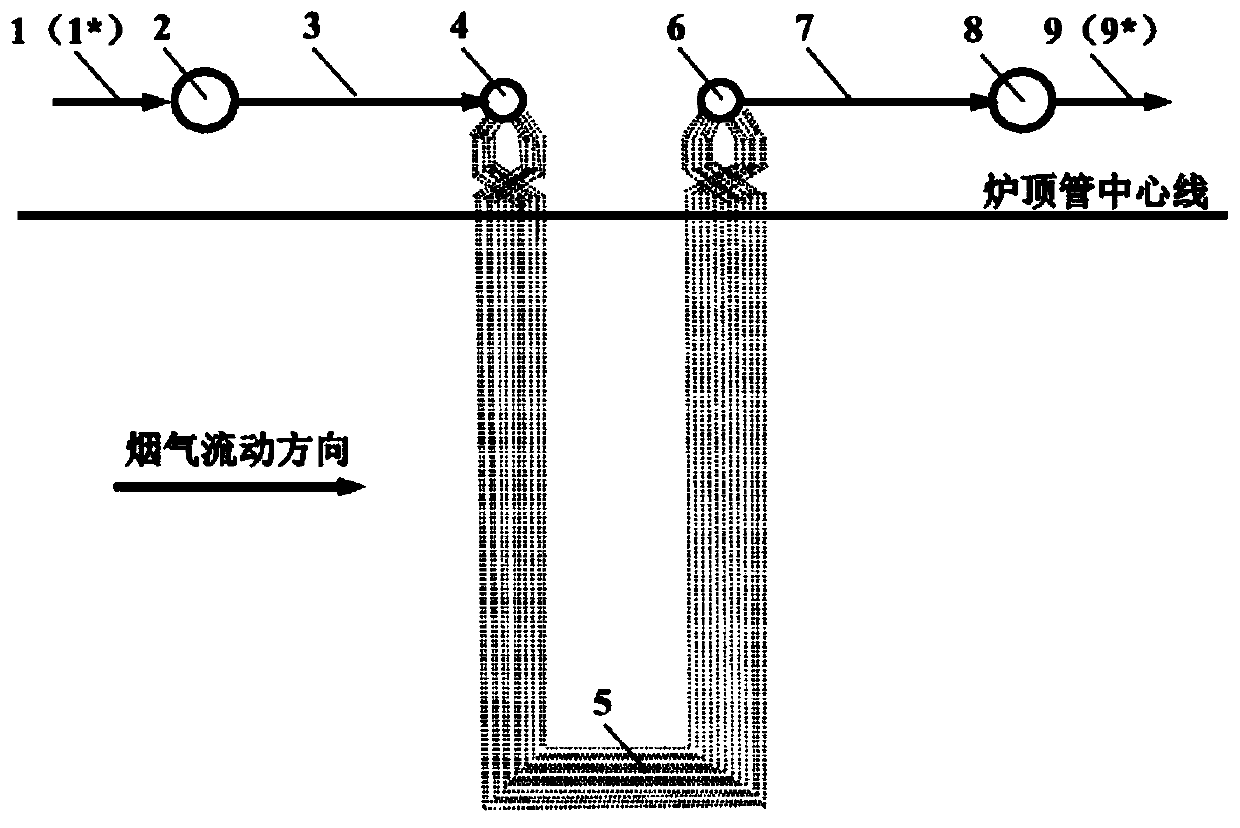

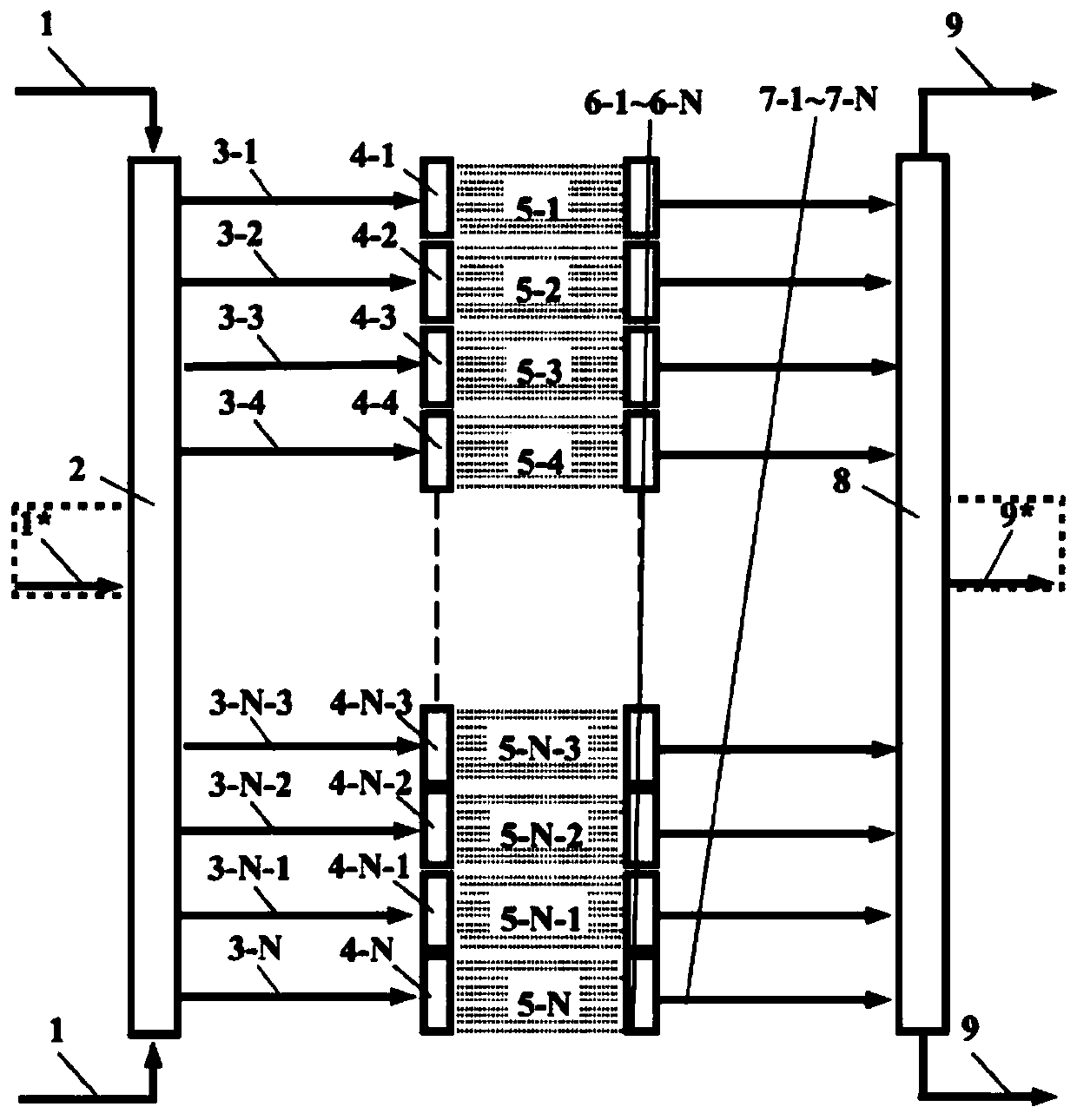

[0012] Such as figure 1 and figure 2 As shown, it is a schematic diagram of a high-temperature heating surface arrangement method for an optimal arrangement method of the high-temperature heating surface provided by the present invention. It includes nine parts in total, and the flow direction of the medium steam in it is the inlet connecting pipe 1, the inlet large header 2, Inlet pipes 3 in each area, small inlet headers 4, high-temperature heating surfaces 5, small outlet headers 6, lead-out pipes 7 in each area, large outlet headers 8, and outlet connecting pipes 9.

[0013] The high-temperature heating surfaces 5 are arranged along the flow and near the furnace outlet, and are scoured horizontally by the high-temperature flue gas. The high-temperature heating surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com