SCR denitration system ammonia spraying quantity optimal control system and method based on intelligent feedforward signals

A feed-forward signal and feed-forward control technology, which is applied in non-electric variable control, chemical instruments and methods, and multiple fluid ratio control, etc., can solve the problems of emissions failing to meet national emission requirements, scaling and corrosion of air preheaters, Ammonia escape increases and other problems, to overcome the delay of the detection system, reduce control overshoot, and save the amount of ammonia injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the content of the present invention more easily understood, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. , After reading the present invention, modifications to various equivalent forms of the present invention by those skilled in the art fall within the scope defined by the appended claims of the present application.

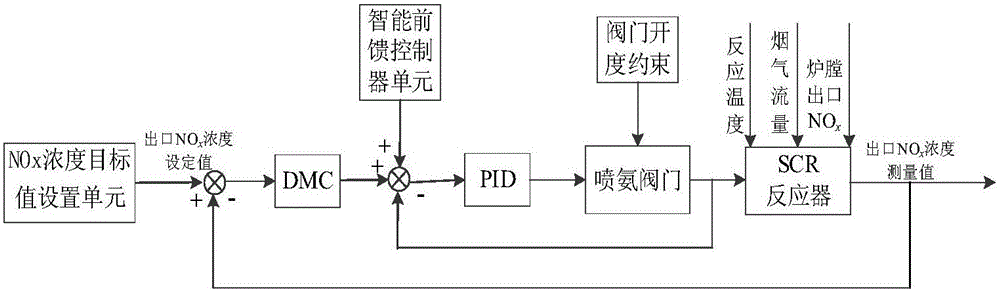

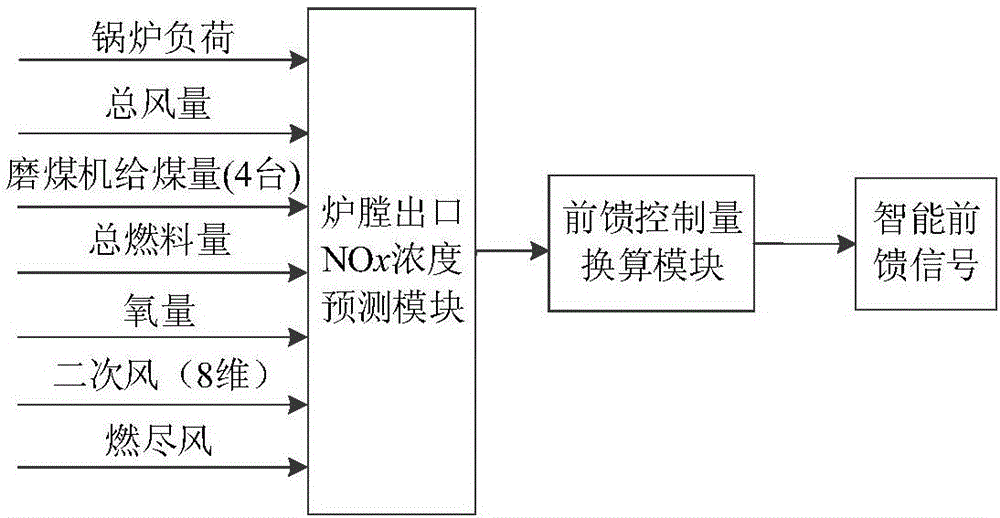

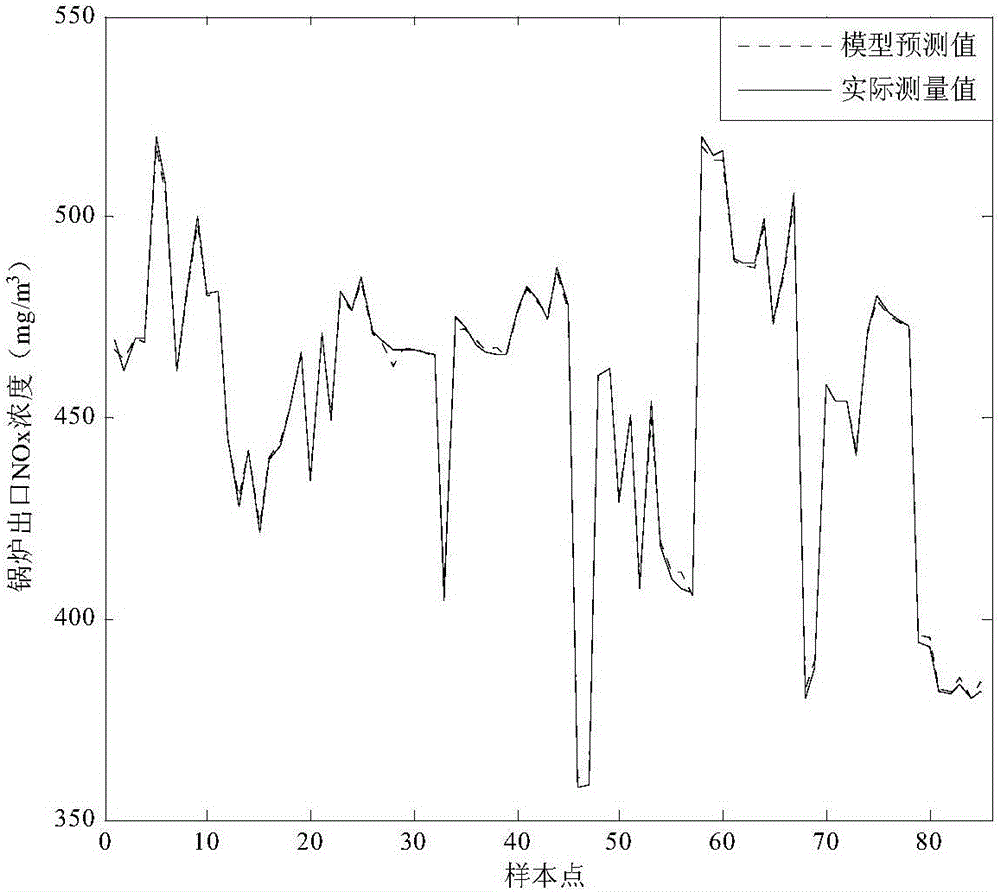

[0033] as attached Figure 1-7 As shown, in order to meet the requirements of wide-ranging changes in operating conditions, the present invention adopts the idea of data modeling, utilizes historical data of power plants, adopts adjustable parameters on the boiler side as input, and takes furnace outlet NO X Concentration is used as the output, and the least squares support ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com