Denitration catalytic performance evaluation system and method

A denitrification catalyst and evaluation system technology, applied in the field of denitrification catalyst performance evaluation system, can solve the problems affecting unit economy, reliability and continuity, low-temperature operation performance attenuation, air preheater clogging and dust accumulation, etc., and the evaluation method is simple Reliability, improved applicability, reduced pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

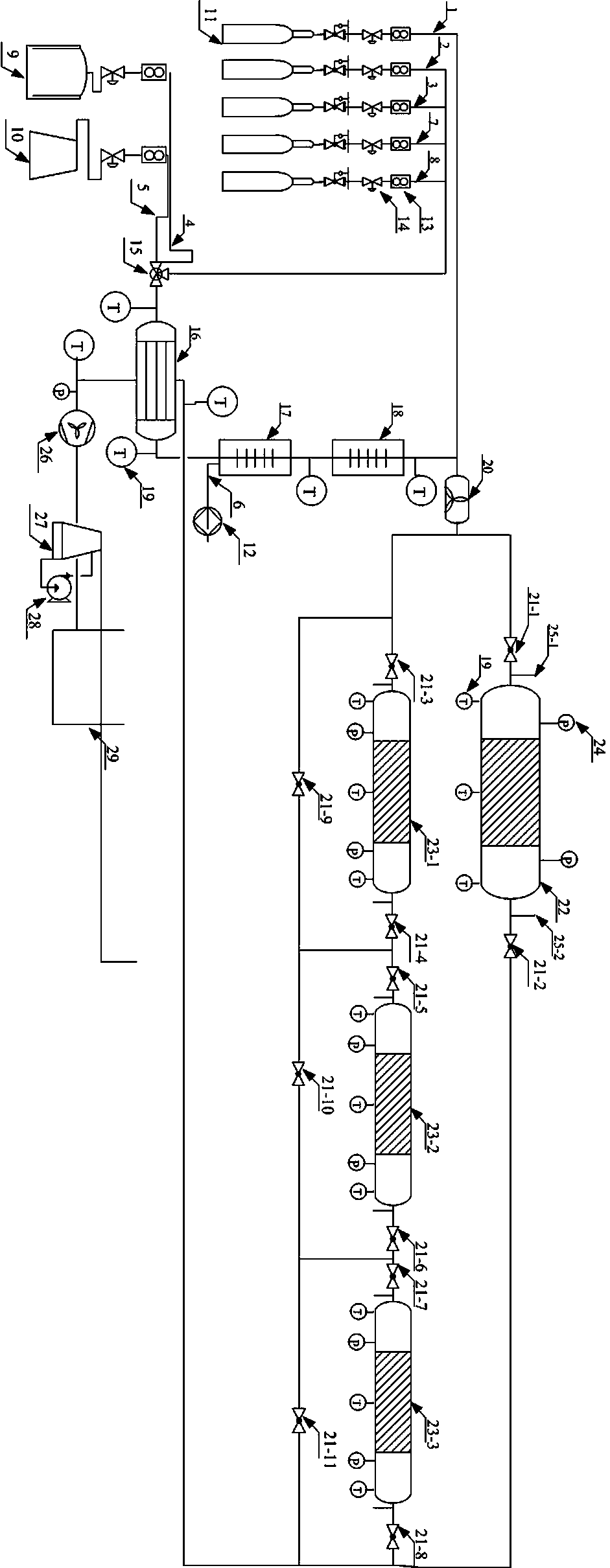

[0028] Such as figure 1 As shown, a denitrification catalyst performance evaluation system, including gas metering system, gas preheating system, SCR catalytic reaction system, gas-gas heat exchanger, tail gas treatment system and control system.

[0029] The denitrification catalyst performance evaluation system is provided with 8 air inlets, respectively NH 3 Inlet 1, SO 2Air inlet 2, NO inlet 3, first backup gas inlet 7, second backup gas inlet 8, nitrogen inlet 4, air inlet 5, water vapor inlet 6, where N 2 Produced by nitrogen production unit 9, O 2 The content is regulated by air compressor 10 introducing air 5, NH 3 , SO 2 , NO, the first backup gas, and the second backup gas use the steel cylinder 11 gas, and the water vapor 6 uses the flow-adjustable metering injection pump 12 to add water and generate through heating.

[0030] NH 3 , SO 2 , NO, N 2 Gas mass flowmeters 13 are installed on each gas pipeline such as air, first standby gas, and second standby gas...

Embodiment 2

[0075] Other steps are identical with embodiment 1, and g step can be replaced by following steps: close valve 21-1, valve 21-2, valve 21-5~valve 21-8, open valve 21-9~valve 21-11, valve 21- 3. The valve 21-4 allows the flue gas flowing out of the mixing device 20 to pass through the second reactor 23-1 and connect the flue gas analyzer to the front sampling port 25-1 and the rear sampling port 25-1 of the second reactor 23-1. 2, Pass the test SO 2 , NO, NO 2 , CO 2 , SO 3 and NH 3 The flue gas concentration of the second reactor 23-1 can be used to obtain the ammonia nitrogen molar ratio, denitrification efficiency, ammonia slip rate and SO 2 / SO 3 Conversion rates.

Embodiment 3

[0077] Other steps are identical with embodiment 1, and g step can be replaced by following steps: close valve 21-1, valve 21-2, valve 21-9~valve 21-11 of the first reactor, open valve 21-3~valve 21- 8. Let the flue gas flowing out of the mixing device 20 pass through the second reactor 23-1, the third reactor 23-2 and the fourth reactor 23-3 in series, and connect the flue gas analyzer to the second reactor 23 -1 front sampling port 25-1 and the fourth reactor 23-3 rear sampling port 25-2, by testing SO 2 , NO, NO 2 , CO 2 , SO 3 and NH 3 The concentration of flue gas can be used to obtain the ammonia nitrogen molar ratio, denitrification efficiency, ammonia slip rate and SO 2 / SO 3 Conversion rates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com