Judgment method and device of service life of catalysts of SCR (Selective Catalytic Reduction) denitration system

A catalyst life and judgment device technology, applied in the field of SCR denitrification system, can solve problems such as inaccurate life judgment, achieve the effect of improving utilization rate, improving calculation results, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

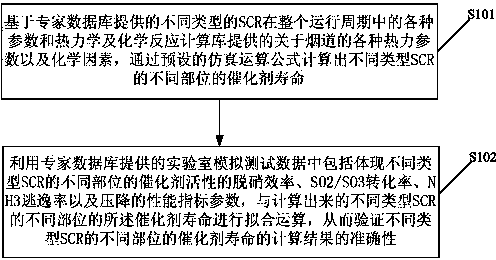

[0036] see figure 1 , is a schematic flow chart of a method for judging the life of a catalyst in an SCR denitration system provided by an embodiment of the present invention. The method for judging the catalyst life of the SCR denitrification system includes steps:

[0037] S101, based on the various parameters of different types of SCRs provided by the expert database in the entire operating cycle and the various thermal parameters and chemical factors of the flue provided by the thermodynamic and chemical reaction calculation library, it is calculated through the preset simulation calculation formula Catalyst lifetime in different parts of different types of SCR;

[0038] S102. Use the laboratory simulation test data provided by the expert database to include the denitrification efficiency, SO2 / SO3 conversion rate, NH3 escape rate and pressure drop performance index parameters that reflect the catalytic activity of different parts of different types of SCRs, which are diff...

Embodiment 2

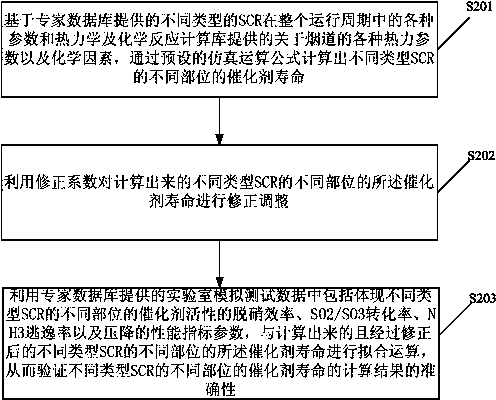

[0095] see figure 2 , is a schematic flow chart of a method for judging the life of a catalyst in an SCR denitration system provided by an embodiment of the present invention. The method for judging the catalyst life of the SCR denitrification system includes steps:

[0096] S201, based on the various parameters of different types of SCRs provided by the expert database in the entire operation cycle and the various thermal parameters and chemical factors of the flue provided by the thermodynamic and chemical reaction calculation library, it is calculated through the preset simulation calculation formula Catalyst lifetime in different parts of different types of SCR;

[0097] S202. Use a correction coefficient to correct and adjust the calculated catalyst lifetimes in different parts of different types of SCRs;

[0098] S203. Use the laboratory simulation test data provided by the expert database to include denitrification efficiency, SO2 / SO3 conversion rate, NH3 escape rate...

Embodiment 3

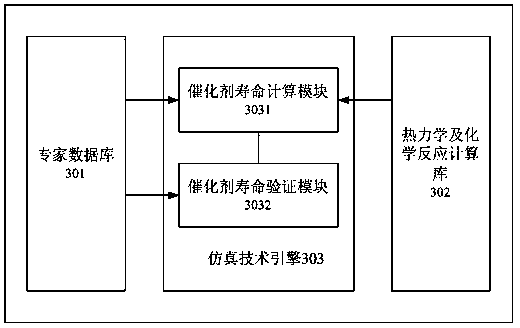

[0101] see image 3, is a structural block diagram of a method for judging the life of a catalyst in an SCR denitration system provided by an embodiment of the present invention. The device for judging the catalyst life of the SCR denitrification system includes

[0102] The expert database 301 is used to provide various parameters of different types of SCRs in the whole operation cycle;

[0103] Thermodynamic and chemical reaction calculation library 302, used to provide various thermodynamic parameters and chemical factors about the flue;

[0104] The simulation technology engine 303 includes a catalyst life calculation module 3031 and a catalyst life verification module 3032, wherein:

[0105] The catalyst life calculation module 3031 is based on the various parameters of different types of SCRs in the entire operation cycle provided by the expert database and various thermal parameters and chemical factors about the flue provided by the thermodynamic and chemical reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com