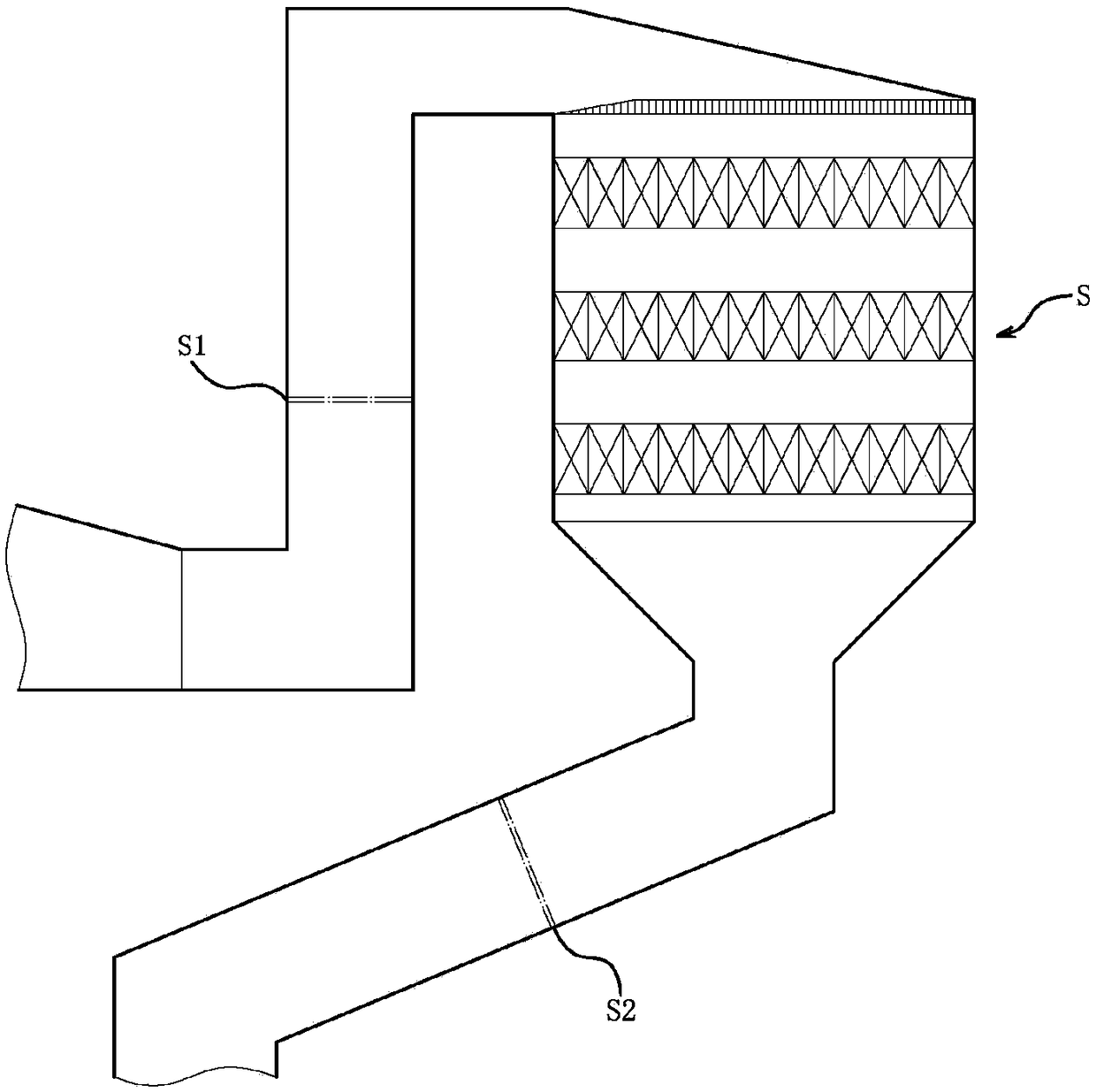

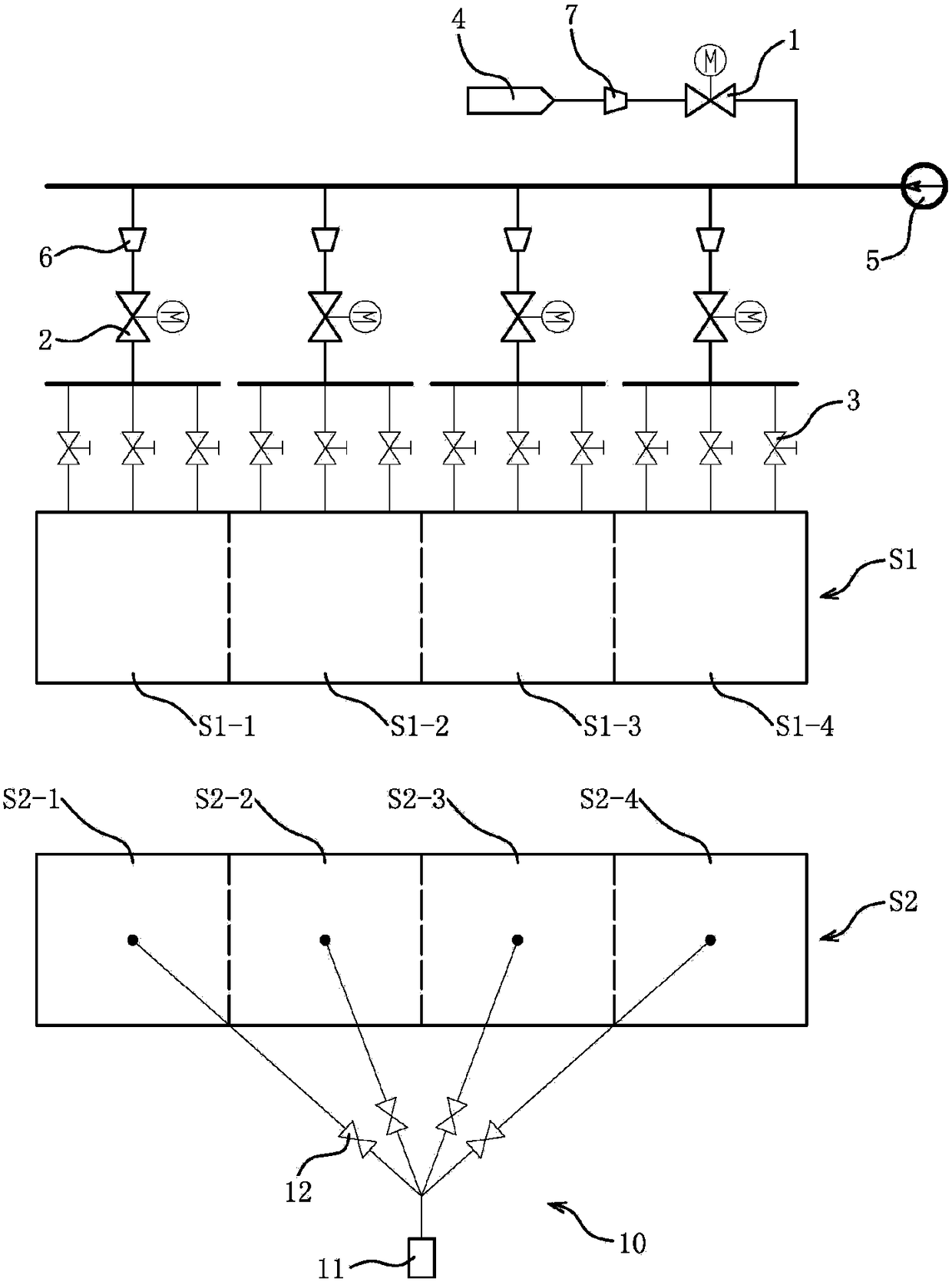

Partitioned ammonia spraying adjustment and control method of SCR (Selective Catalytic Reduction) denitration device

An adjustment control and denitrification technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as difficulty in ensuring real-time measurement and affecting the quality of leveling valves in ammonia injection zones, so as to eliminate adverse effects and improve Quality, the effect of reducing ammonia slip rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The 600MW coal-fired unit adopts SCR denitrification device to reduce the NOx emission concentration in the flue gas. The reducing agent is liquid ammonia. According to the technical scheme, the inlet ammonia injection section and the outlet measurement section are virtually divided into four sections of the same size, and the section size of each section is 3.6m×3.2m.

[0033] For example, a set of CEMS instruments is installed at the inlet of the SCR denitrification device on each side. Under a certain working condition, the NOx concentration at the inlet of the SCR denitrification device is 350mg / Nm 3 , according to the requirements of the ultra-low emission standard, the NOx concentration control value at the outlet of the SCR denitrification device is 35mg / Nm 3 . The measured values of ammonia flow in each zone at the inlet of the SCR denitrification device are 24.4, 25.6, 25.3, and 26.1kg / h, respectively, and the corresponding NOx concentrations in each zone at...

Embodiment 2

[0039] The system composition is the same as that of the implementation 1 coal-fired unit, and the technical conditions of the example are also the same. The process of determining the target value of the ammonia flow adjustment in each zone is as follows:

[0040] The initial value of the ammonia flow adjustment target in the first zone = 23.08kg / h;

[0041] The initial value of the ammonia flow adjustment target in the second zone = 25.20kg / h;

[0042] The initial value of the ammonia flow adjustment target in the third zone = 25.88kg / h;

[0043] The initial value of the ammonia flow adjustment target in the fourth zone = 27.87kg / h.

[0044] Initial value correction factor=(24.4+25.6+25.3+26.1)÷(23.08+25.20+25.88+27.87)=0.9938

[0045] The target value of ammonia flow adjustment in the first zone = 23.08 × 0.9938 = 22.94kg / h;

[0046] The target value of ammonia flow adjustment in the second zone = 25.20 × 0.9938 = 25.04kg / h;

[0047] The target value of ammonia flow adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com