Method for evaluating the denitration capability of an SCR reactor

An SCR reactor and denitrification technology, applied in instruments, data processing applications, special data processing applications, etc., can solve the problems of time-consuming and labor-intensive, unable to reflect the flue gas flow field, etc., and achieve the effect of avoiding prediction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

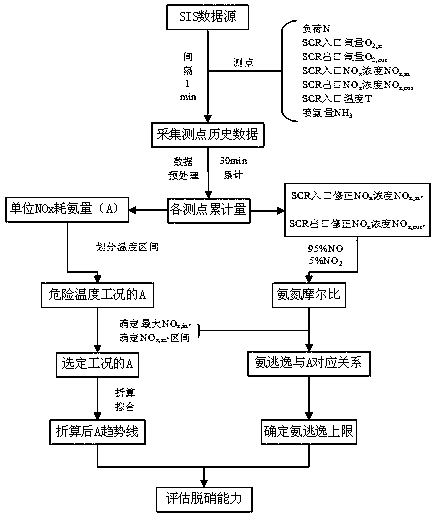

[0045] Taking the B-side reactor of a 660MW coal-fired power generation unit as an example, the data in the SIS system was collected from July 2016 to September 2017, and the collection interval was 1 minute. The framework of the present invention is mainly composed of core modules such as data acquisition, data preprocessing, data processing, division of working conditions, and fitting and conversion of A trend line. The detailed flow chart is as follows figure 1 Shown:

[0046] 1) Obtain the data of each measuring point from the SIS data source, and collect the load N and SCR inlet oxygen O at intervals of 1 min 2,in , SCR outlet oxygen O 2,out , SCR inlet NOx concentration NO x,in , SCR outlet NOx concentration NO x,out , SCR inlet temperature T and ammonia injection amount NH 3 Some data such as measuring points are shown in Table 1.

[0047] Table 1

[0048]

[0049]

[0050] Clamp each item of data to normal operating ranges and delete values that remain un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com