Method for strengthening aluminum ash denitriding through pressure regulating-water hot rotational flow technology

A technology for denitrification and aluminum ash, applied in the direction of solid waste removal, etc., can solve problems such as aluminum ash pollution, achieve the effect of shortening the time and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

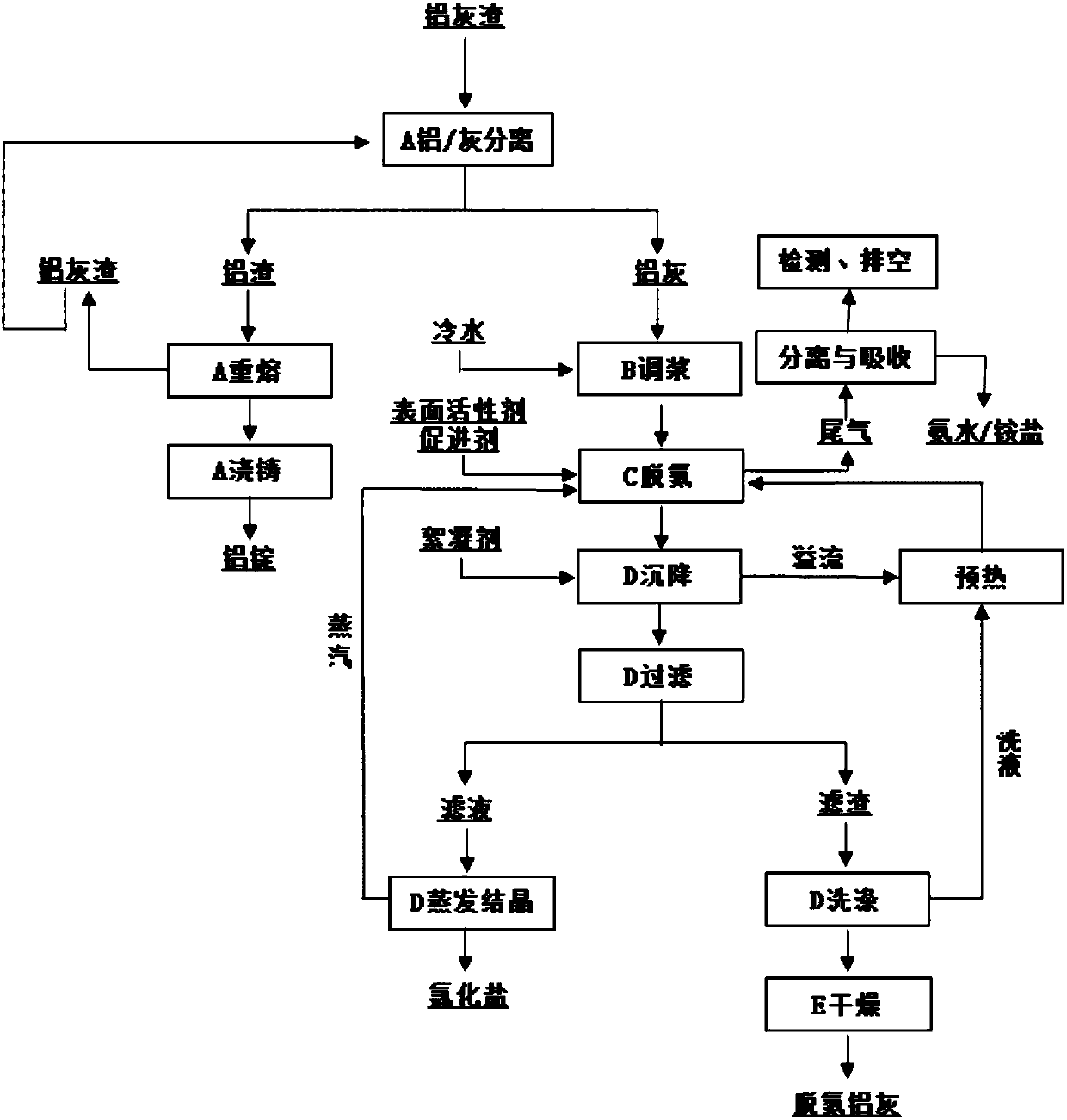

Method used

Image

Examples

Embodiment 1

[0031] Step 1, gray aluminum separation: take 1.25t aluminum ash slag, separate the metal aluminum in the aluminum ash slag, and remelt the separated metal aluminum into aluminum ingots;

[0032] Step 2, feeding: add 1 ton of aluminum ash obtained after aluminum extraction, add 1 ton of cold water to make slurry, the temperature of cold water is 15-30°C, inject into the reactor, add 1 ton of preheated water at 50°C to the reactor, and Add surfactant (preferably 50kg sodium hexametaphosphate), and accelerator (preferably 100kg sodium hydroxide);

[0033] Step 3, denitrification: The reaction conditions are temperature 80°C, swirl speed 80r / min, the pressure regulation process takes 120min as a cycle, and one cycle is decompression to maintain the pressure in the tank at 0.01MPa for 90min, and then pressurize to make the pressure in the tank Maintain 0.10MPa for 30 minutes, complete 2 pressure adjustment cycles during the denitrification process, the reaction time is 4 hours, an...

Embodiment 2

[0039] Step 1, ash / aluminum separation: take 1.25t of aluminum ash slag, separate the metal aluminum in the aluminum ash slag, and remelt the separated metal aluminum into aluminum ingots;

[0040] Step 2, material: Add 1.5t of cold water to slurry the obtained aluminum ash after extracting aluminum, the temperature of cold water is 15-30°C, inject it into the reactor, add 3.5t of preheated water at 80°C into the reactor, And add 1kg sodium dodecylbenzenesulfonate and 0.1kg sodium bicarbonate;

[0041] Step 3, denitrification: the reaction conditions are temperature 150°C, swirl speed 40r / min, the pressure regulation process takes 240min as a cycle, and one cycle is decompression to maintain the pressure in the tank at 0.09MPa for 60min, and then pressurize to make the pressure in the tank Maintain 0.20MPa for 180 minutes, complete 2 pressure adjustment cycles during the denitrification process, the reaction time is 8 hours, and the mixed gas of ammonia and water vapor generat...

Embodiment 3

[0045] Step 1, ash / aluminum separation: take 1.25t of aluminum ash slag, separate the metal aluminum in the aluminum ash slag, and remelt the separated metal aluminum into aluminum ingots;

[0046] Step 2, feeding: Add 1t of aluminum ash obtained after aluminum extraction, add 2t of cold water to make slurry, the temperature of cold water is 15-30°C, inject it into the reactor, add 8t of preheated water at 80°C into the reactor, and Add 10kgCTAB, 10kg sodium hexametaphosphate and 10g sodium dodecylbenzenesulfonate mixture as surfactant, and 5kg sodium carbonate as accelerator;

[0047] Step 3, denitrification: the reaction conditions are temperature 110°C, swirl speed 10r / min, the pressure regulation process takes 30min as a cycle, and one cycle is decompression to keep the pressure in the tank at 0.01MPa for 15min, and then pressurize to make the pressure in the tank Maintain 0.20MPa for 15 minutes, complete 2 pressure adjustment cycles during the denitrification process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com