Modifying method for catalyst activity in power plant SCR (selective catalytic reduction) denitration system

A catalyst and denitration technology, applied in chemical instruments and methods, separation methods, chemical analysis using catalysis, etc., can solve the problems of inability to simulate the effect of fly ash, small size of the reactor, affecting system performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

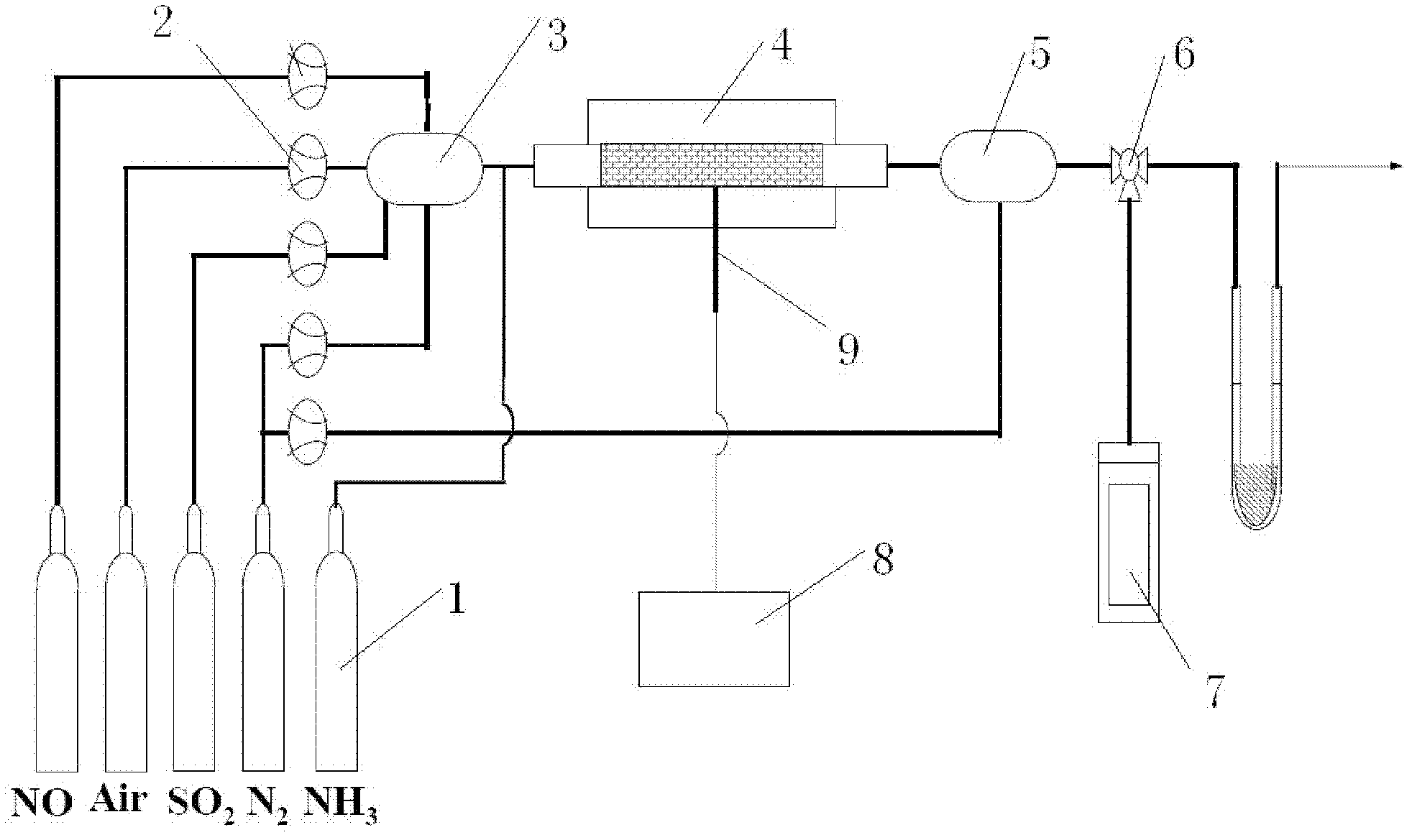

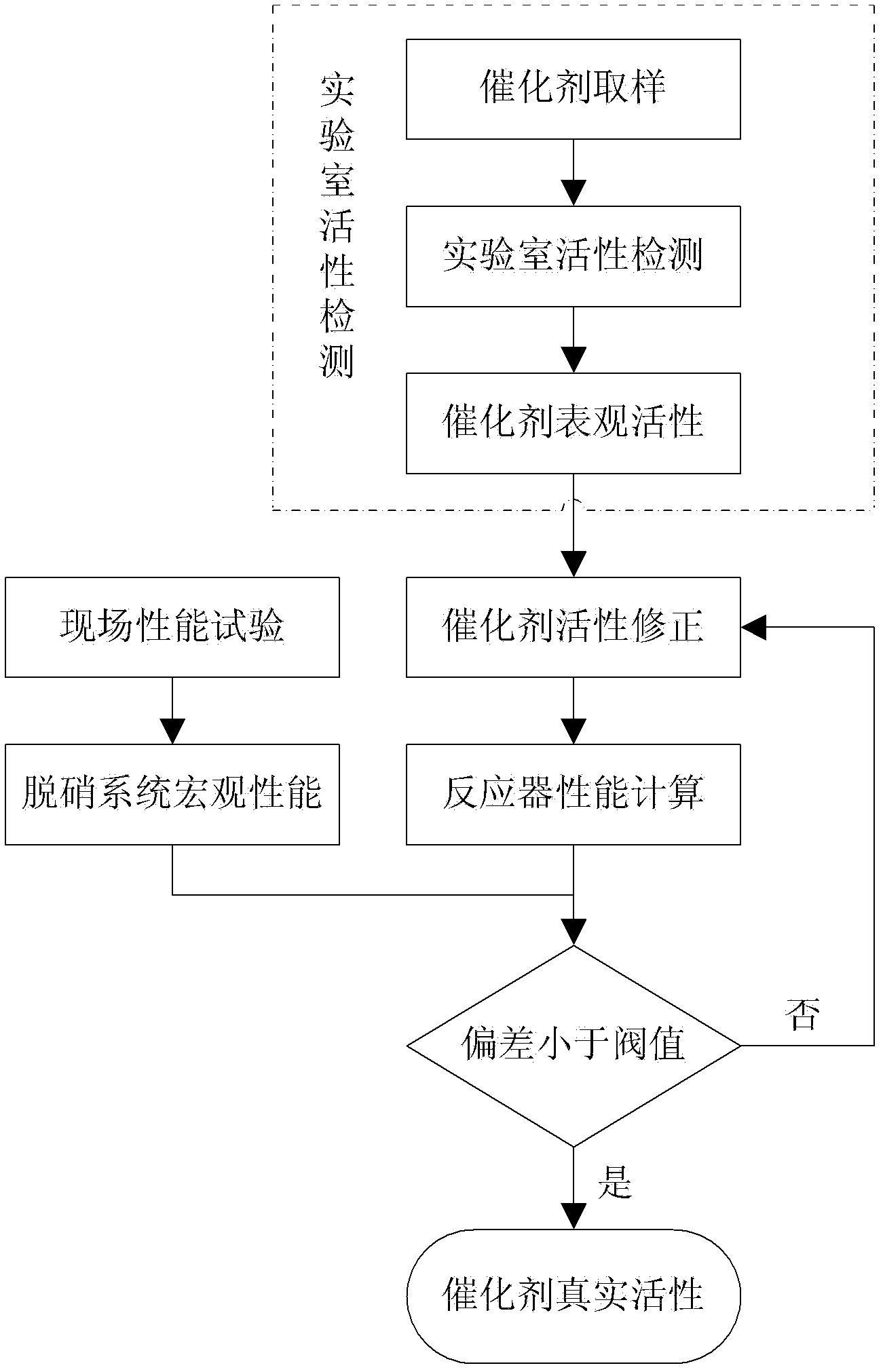

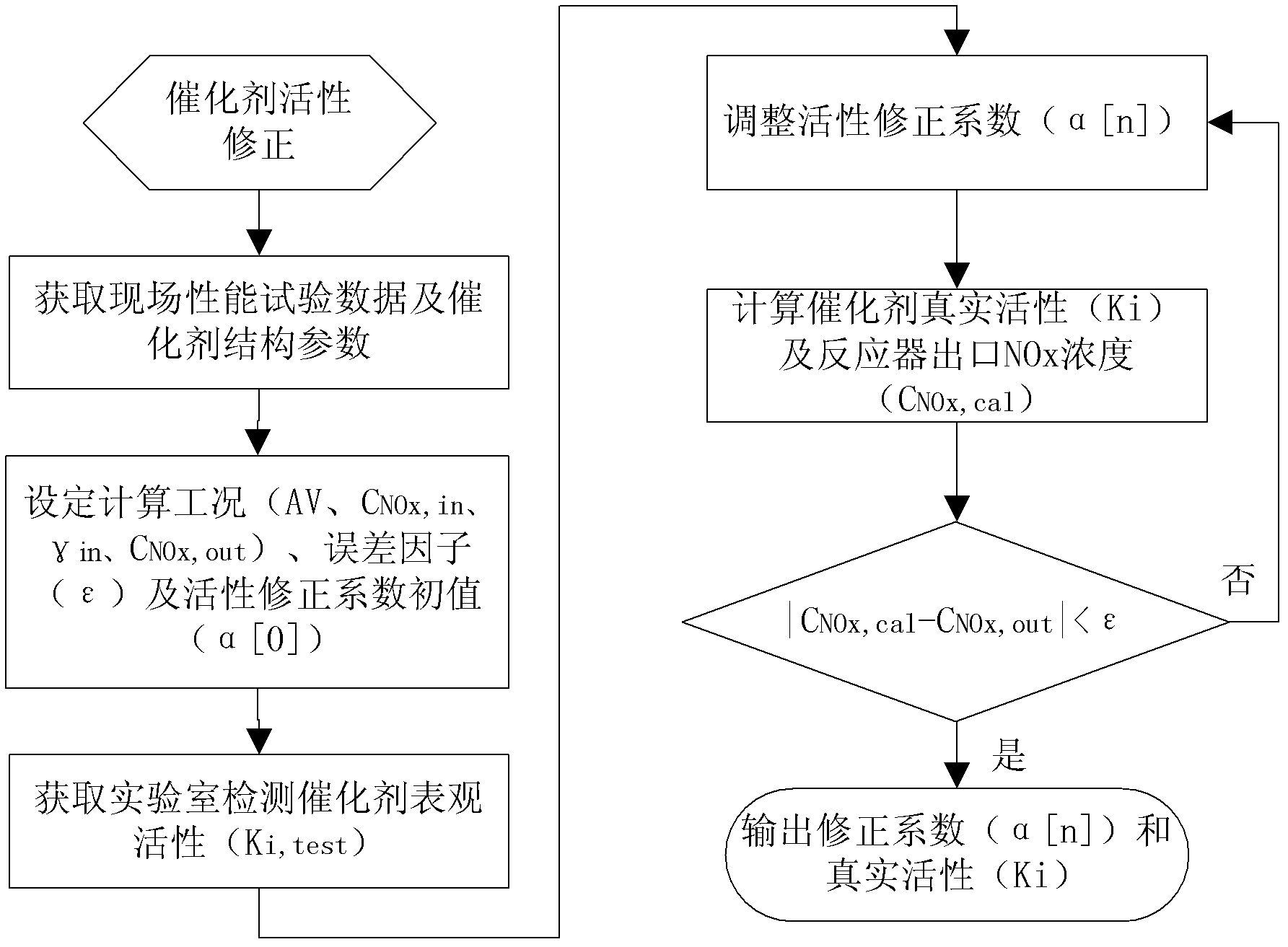

Method used

Image

Examples

Embodiment

[0068] A 600MW coal-fired unit is equipped with a set of SCR flue gas denitrification system, including two reactors A and B. Each reactor was packed with two layers of catalyst. The catalyst structural parameters, field performance test parameters and catalyst apparent activity detection values are shown in Table 1, Table 2, and Table 3, respectively, and the revised results are shown in Table 4.

[0069] Table 1: Catalyst structure parameters

[0070]

[0071] Table 2: Field performance test parameters

[0072]

[0073] Table 3: Catalyst apparent activity (Nm / h)

[0074]

[0075] Table 4: Catalyst activity correction results

[0076]

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com