Preparation method for fluororubber cladding nanometer aluminum powder composite particles

A technology of nano-aluminum powder and composite particles, which is applied in the direction of nanotechnology, can solve the problems of energy reduction and compatibility, and achieve the effects of short preparation cycle, improved compatibility and prevention of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

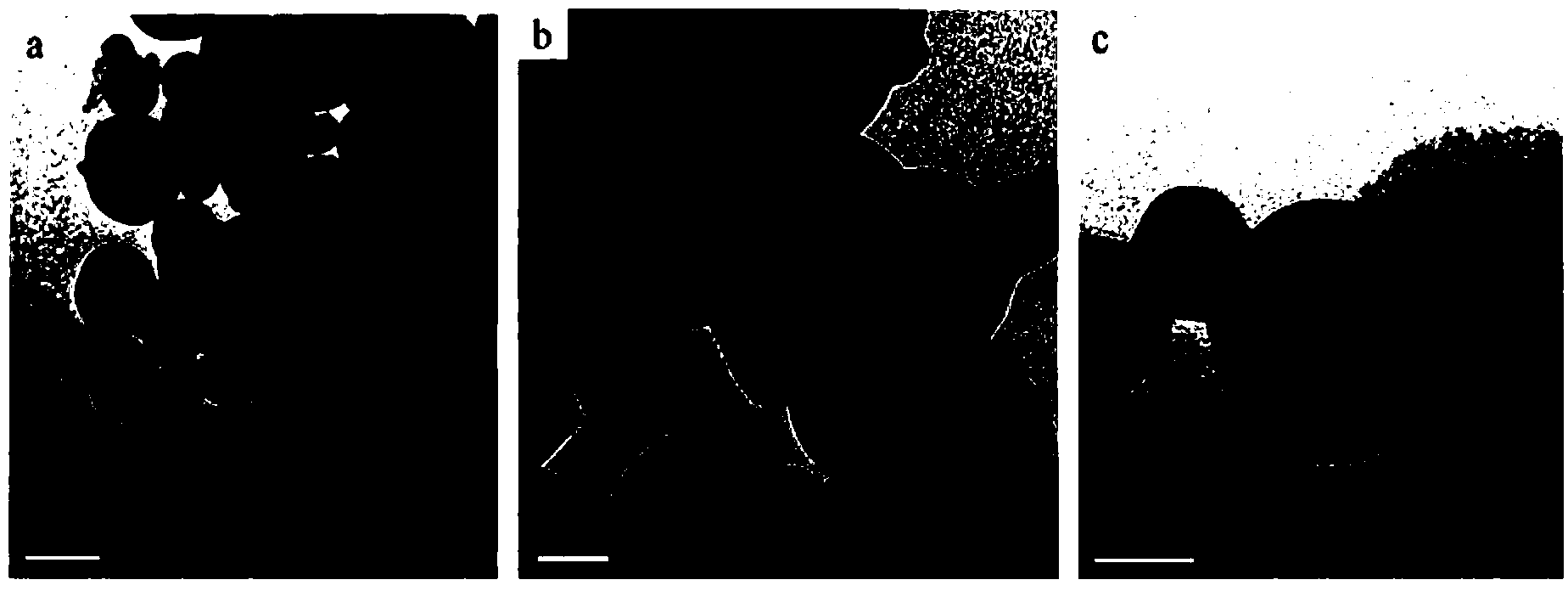

Image

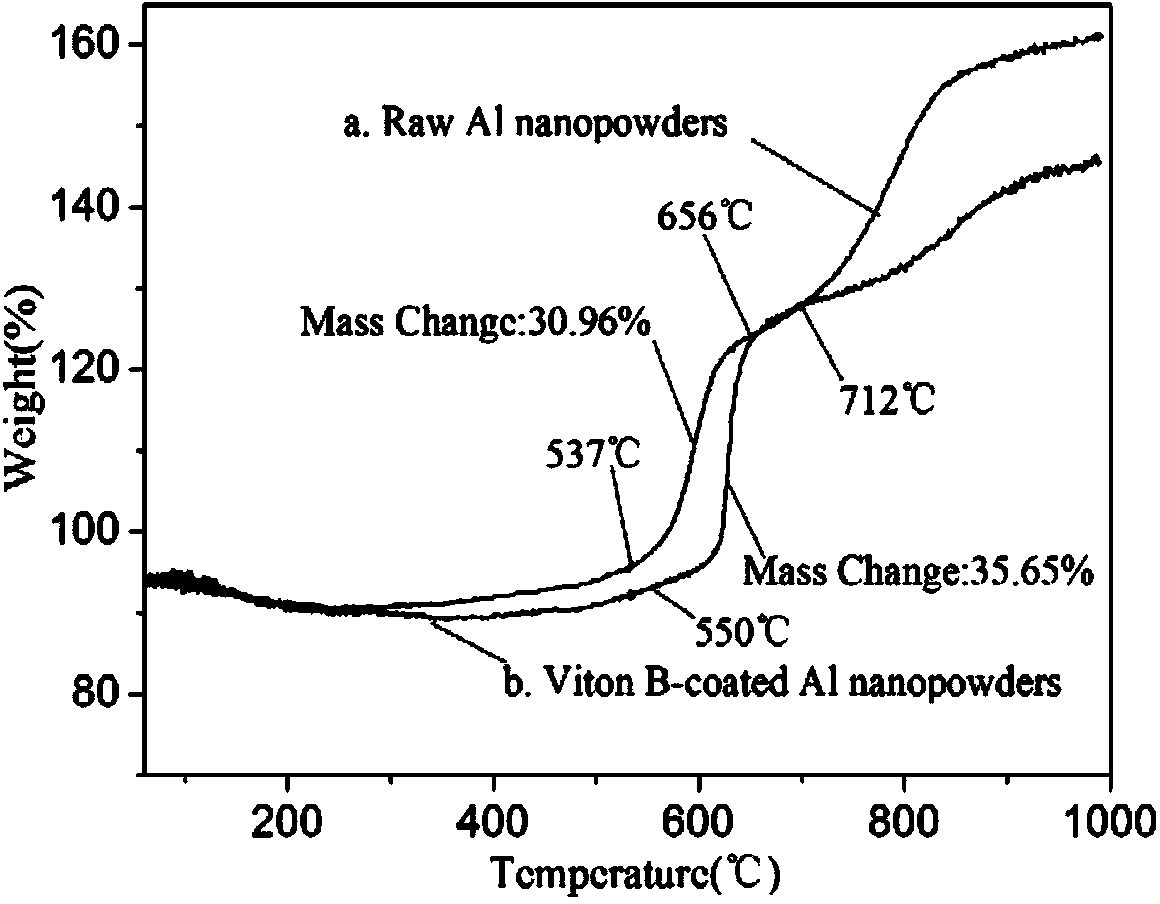

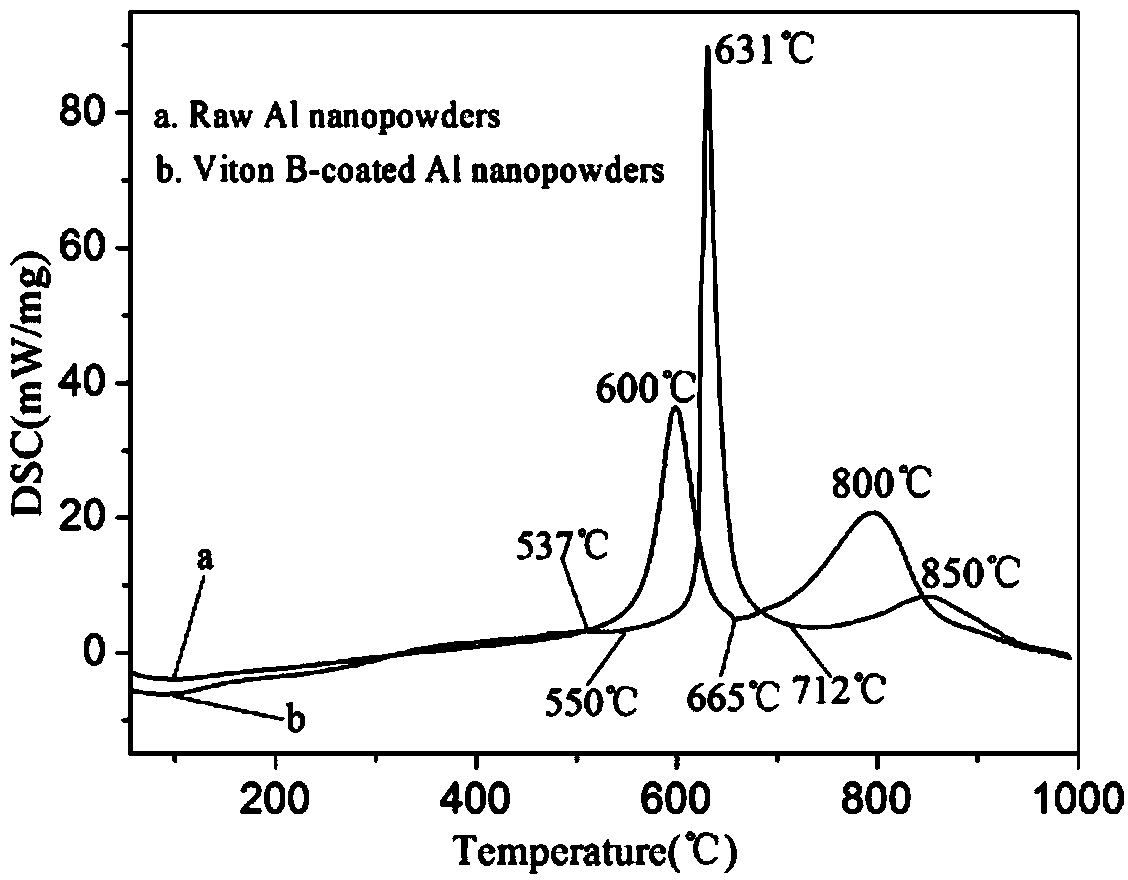

Examples

Embodiment 1

[0024] (1) In an inert gas (N 2 ) Weigh 5g of nano-aluminum powder with an average particle size of 80nm in the glove box, and quickly add it to a three-necked flask filled with 100mL of absolute ethanol. 2 Under protective conditions, ultrasonically disperse for 20 minutes to disperse the nano-aluminum powder evenly; weigh 0.25g of silane coupling agent KH-560, add it to the suspension of nano-aluminum powder, continue ultrasonically dispersing for 30 minutes, and stir in a constant temperature water bath at 60°C at 300rpm After 3 hours, cool to room temperature, filter, and vacuum-dry at 60°C for 12 hours to obtain KH-560 modified nano-aluminum powder.

[0025] (2) Weigh 0.36g of pre-dried fluororubber 26 (Viton A), add it to 120mL of ethyl acetate, place it in a 70°C water bath and heat for 30min to prepare the ethyl acetate solution of fluororubber 26 (3g / L), After cooling to 25°C, seal it for later use. Weigh 3.68g of modified nano-aluminum powder, add 61.3mL of ethyl a...

Embodiment 2

[0027] (1) In an inert gas (N 2 ) Weigh 5g of nano-aluminum powder with an average particle size of 80nm in the glove box, and quickly add it to a medium three-necked flask filled with 150mL of absolute ethanol. 2 Under protective conditions, ultrasonically disperse for 20 minutes to uniformly disperse the nano-aluminum powder in anhydrous ethanol; then weigh 0.5 g of aminosilane coupling agent KH-550, add it to the suspension of nano-aluminum powder, and continue ultrasonically dispersing for 30 minutes. in N 2 Stir at 400 rpm for 2 hours in a constant temperature water bath at 65°C under protected conditions, cool to room temperature after stirring, filter, and vacuum dry at 60°C for 12 hours to obtain KH-550 modified nano-aluminum powder.

[0028] (2) Weigh 0.48g of pre-dried fluororubber 246 (Viton B), add it to 120mL of acetone, place it in a 70°C water bath and heat it under reflux for 30min, prepare the acetone solution of fluororubber 246 (4g / L), cool to 25 After ℃, ...

Embodiment 3

[0034] (1) In an inert gas (N 2 ) Weigh 5g of nano-aluminum powder with an average particle size of 80nm in the glove box, and quickly add it to a three-necked flask filled with 150mL of absolute ethanol. 2 Under protective conditions, ultrasonically disperse for 30 minutes to disperse the nano-aluminum powder evenly; weigh 0.75g of silane coupling agent KH-570, add it to the suspension of nano-aluminum powder, continue ultrasonically dispersing for 30 minutes, and stir in a constant temperature water bath at 65°C at 500rpm After 2 hours, cool to room temperature, filter, and vacuum-dry at 60°C for 12 hours to obtain KH-570 modified nano-aluminum powder.

[0035] (2) Weigh 1.2g of pre-dried fluororubber 23 (Kel-F-rubber), add it to 120mL ethyl acetate, place it in a 70°C water bath and heat for 30min, and prepare the ethyl acetate solution of fluororubber 23 (10g / L), cooled to 25°C and sealed for later use. Weigh 4g of nano-aluminum powder modified by KH-570, add 80mL of et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com