Mercaptan removal and lye regeneration device and method for gasoline light fractions

A light-distillate and desulfurization technology is applied in the field of devices for desulfurization of gasoline light-ends and lye regeneration, and can solve the problems of loss of gasoline octane number, huge investment in the process of desulfurization of gasoline light-ends, and high cost of gasoline refining.

Active Publication Date: 2012-10-31

NINGBO ZHONGYI PETROCHEM TECH

View PDF7 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The purpose of the present invention is to provide a gasoline light fraction sweetening and lye regeneration device and method to solve technical problems suc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

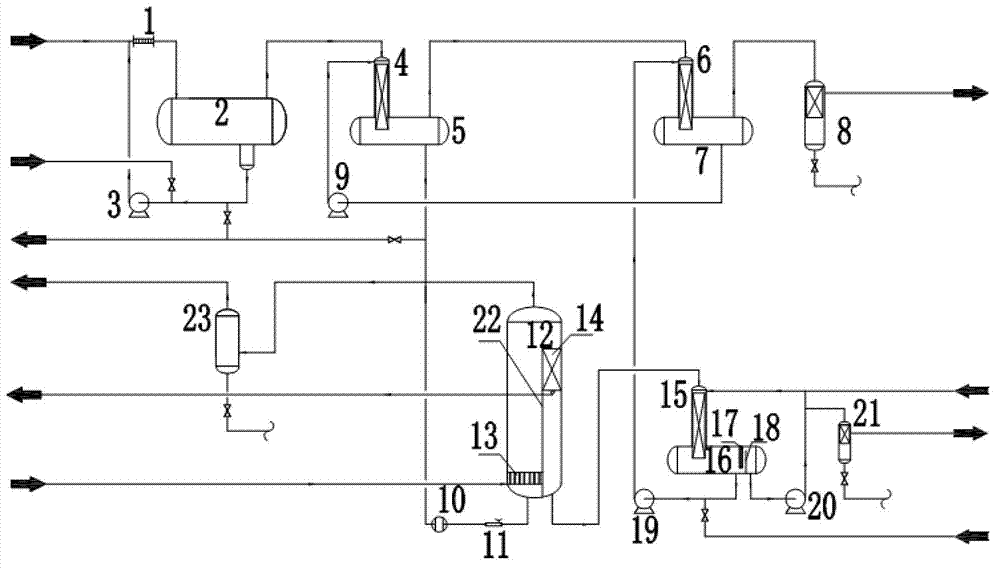

The invention relates to a mercaptan removal and lye regeneration device and a method for gasoline light fractions. The mercaptan removal and lye regeneration device for gasoline light fractions comprises a static mixer, a liquid film alkaline wash reactor, a lye coalescence remover, a lye oxidation separation tower and a liquid film extraction contactor. The mercaptan removal and lye regeneration device and the method for gasoline light fractions have the advantages that pre-alkaline washing is used for removing hydrogen sulfide and phenol, so that the investment is low; the two-stage liquid film alkaline wash reactor and the alkaline wash process are utilized, so that the mercaptan in products can be guaranteed to be below 10 parts per million (ppm), no free lye is carried, and the copper sheet corrosion and water-solutbility acid base detection can be guaranteed to be qualified with no water wash needed; the oxidation rate of mercaptan sodium in the lye is high, two-phase perturbation emulsification is quite slight, and more than 60% of generated disulphide can be separated and recycled; the content of the disulphide in the regenerated lye can be guaranteed to be no more than 100 ppm, and the regenerated lye cannot be re-extracted into products when used for removing mercaptan in a circulation mode; the total sulfur in products can be guaranteed to be stable and not rise without replacing the lye frequently, and compared with other processes, the discharge amount of alkaline residues is reduced by more than 50%.

Description

technical field [0001] The invention relates to the field of petrochemical industry, in particular to a device and method for sweetening gasoline light fraction and regenerating lye. Background technique [0002] With the inferior quality and high vulcanization of crude oil, and the society's increasing requirements for gasoline fuel desulfurization, oil refineries are required to continuously improve the level of crude oil processing technology, continuously improve the gasoline fuel desulfurization process, and at the same time pay more attention to energy saving, emission reduction and consumption reduction in the production process sustainable production needs. [0003] Developed countries in Europe and the United States began to implement the Euro IV standard for clean gasoline as early as 2005, and the Euro V standard in 2009. my country also took the lead in implementing the National IV standard in Beijing, Shanghai and other places in 2011, requiring the total sulfur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G19/02C10G19/08

Inventor 喻武钢聂通元王铭童仁可徐振华蔡喜洋

Owner NINGBO ZHONGYI PETROCHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com