Adsorption technique

A technology and adsorption tower technology, applied in the field of gas separation and purification, high-efficiency adsorption technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

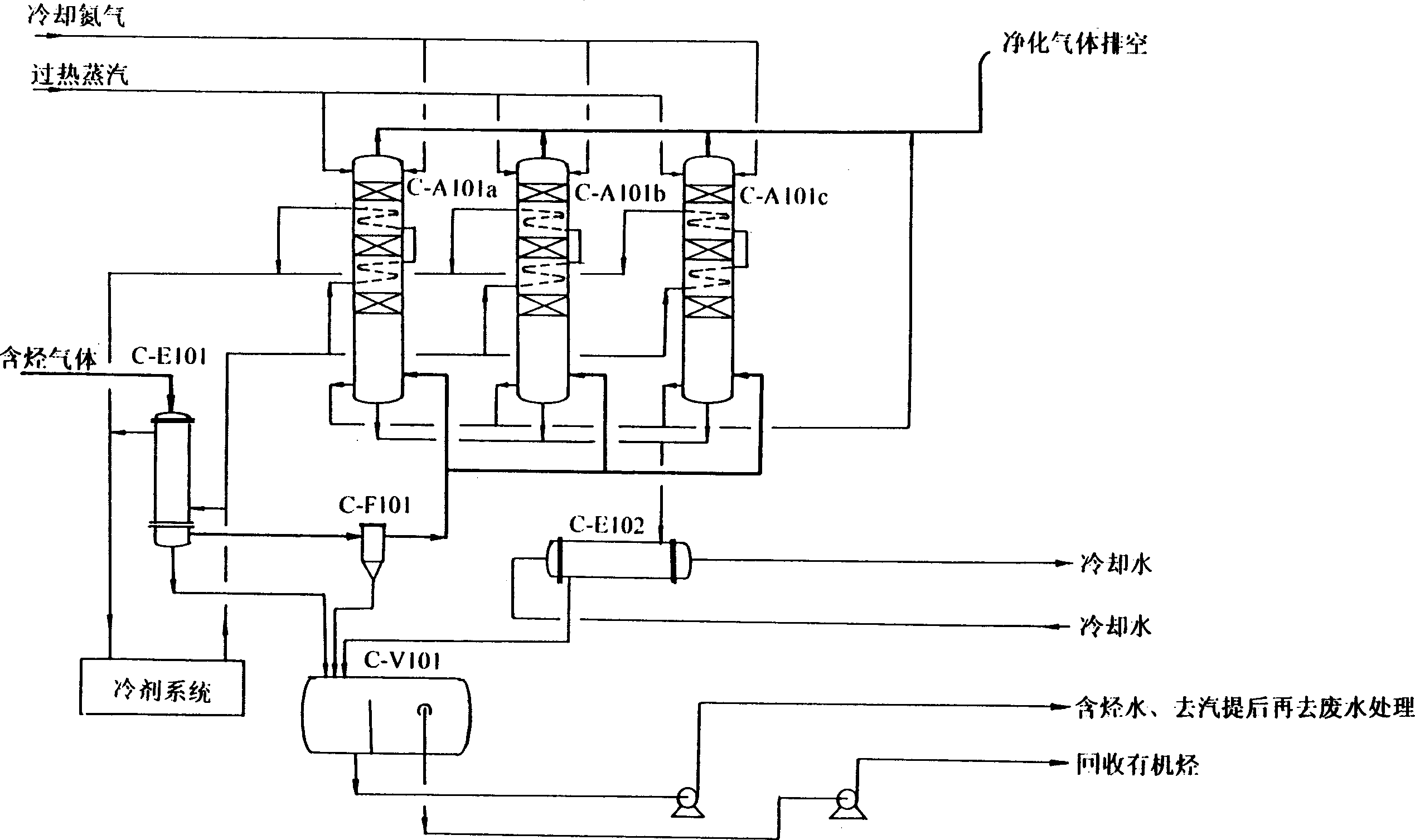

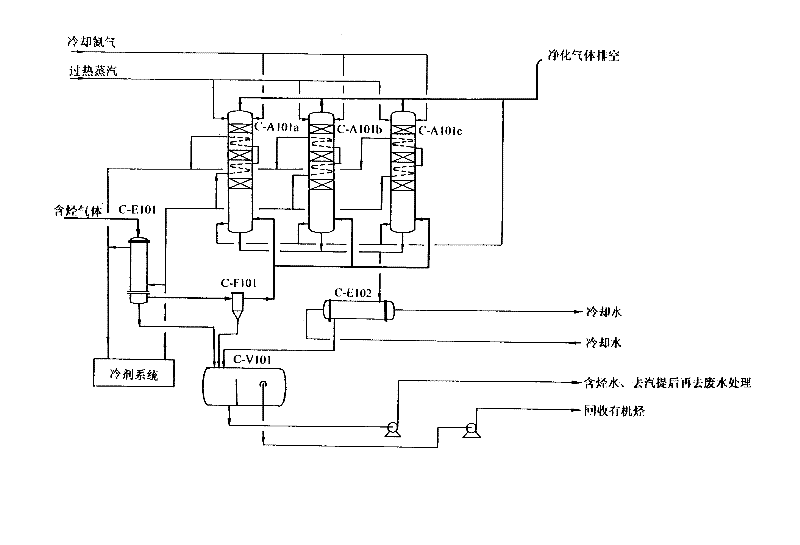

[0009] Refer to the attached figure, the pollutant gas containing organic hydrocarbons (with a certain pressure, if the atmospheric pressure gas or the gas that is not enough to overcome the resistance of the adsorbent bed and the system, a supercharger should be added to the system) first enter the condensing cooler C -E101, where some organic hydrocarbons (such as aromatics, etc.) are condensed and flow into the oil-water separation tank C-V101. After the uncondensed pollutant gas passes through the demister C-F101, it flows into the activated carbon adsorption tower C-A101 system. In this example, three identical adsorption towers are set up. The adsorption gas only enters one of them by switching the valve, for example, At the bottom of C-A101a, through the multi-layer activated carbon fixed bed and built-in cooler, organic hydrocarbons are adsorbed by the activated carbon, and the adsorption heat is also continuously removed through the built-in cooler, so that the activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com