Method and system of preparing spongy iron by using gas-based shaft furnace

A gas-based shaft furnace and sponge iron technology, applied in the field of metallurgy, can solve the problems of large-scale reducing gas heating equipment, unsatisfactory sponge iron carburizing effect and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

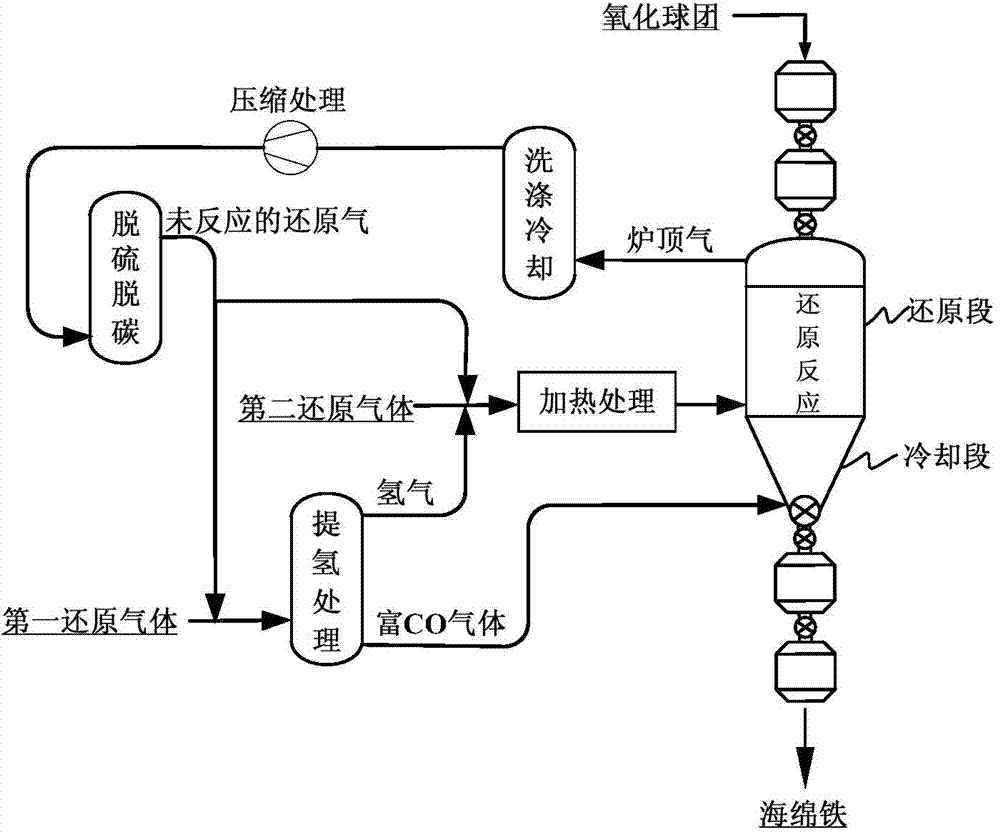

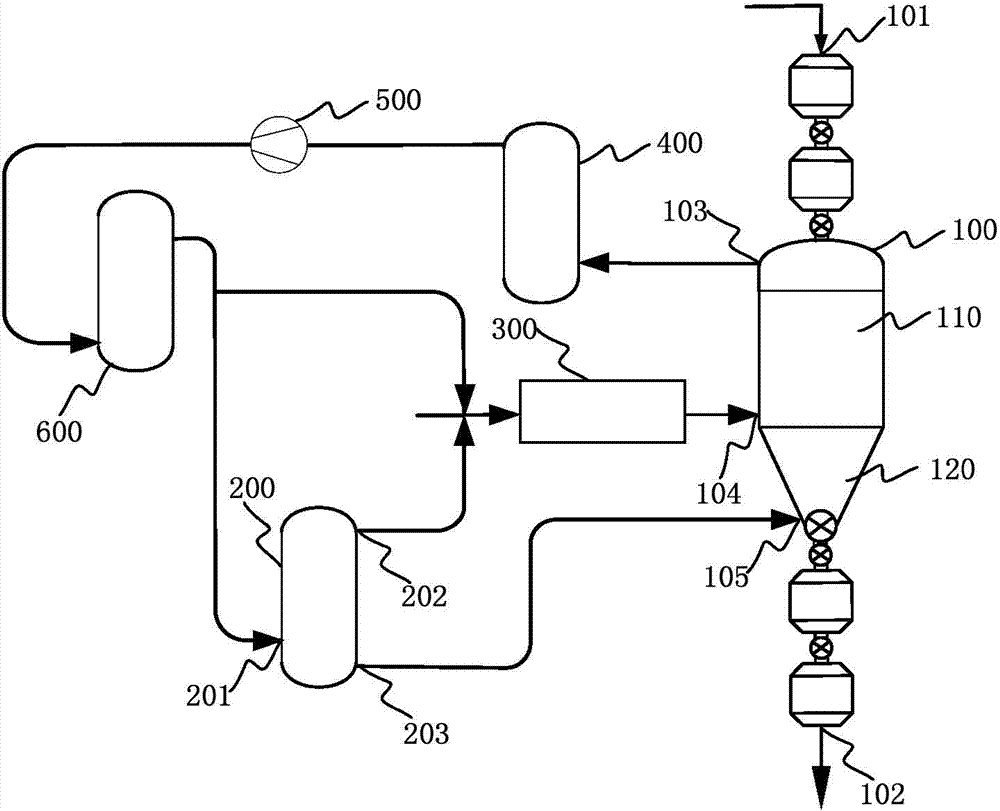

[0064] Such as Figure 1-2 As shown, the fresh reducing gas is divided into two parts, one part passes through the gas hydrogen extraction device, and this part of the gas is divided into hydrogen and carbon monoxide-rich gas, and the hydrogen and the other part of the fresh reducing gas are passed into the gas heating furnace for heating to 900-1000 degrees Celsius, and then enter the shaft furnace reduction section from the surrounding pipe at the bottom of the shaft furnace reduction section to carry out reduction reaction with the oxidized pellets entering from the upper part of the shaft furnace. The carbon monoxide-rich gas passes into the bottom of the cooling section of the shaft furnace, exchanges heat with the hot sponge iron, and cools the sponge iron to below 50°C in the cooling section of the shaft furnace, and at the same time, a part of carbon monoxide is consumed by the carburizing reaction. This part of the carbon monoxide-rich gas is heated to 850-900 degrees C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com