Gate type plate shearing machine

A shearing machine and gate-type technology, which is applied in the field of machine tools, can solve problems such as machining errors of the fuselage, broken double-ended studs, and double-ended studs deviate from the center position, and achieve the effect of meeting the shearing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

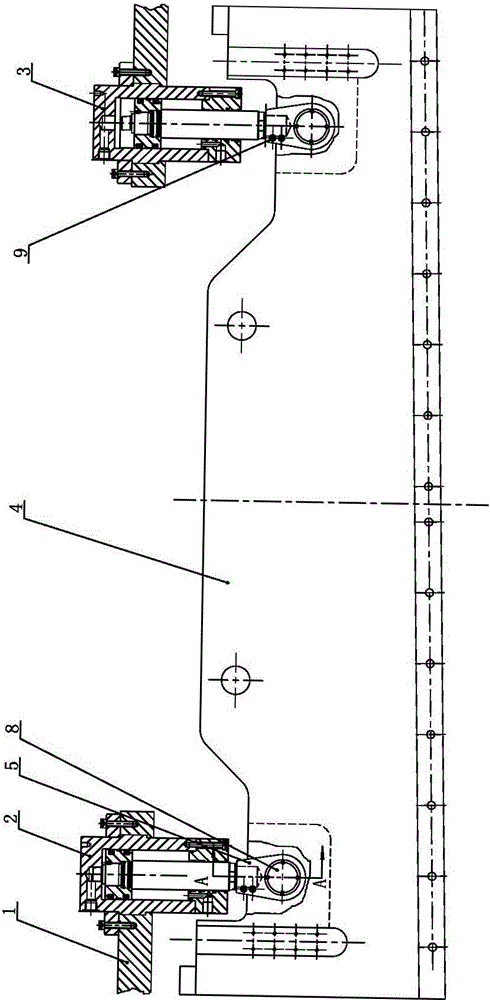

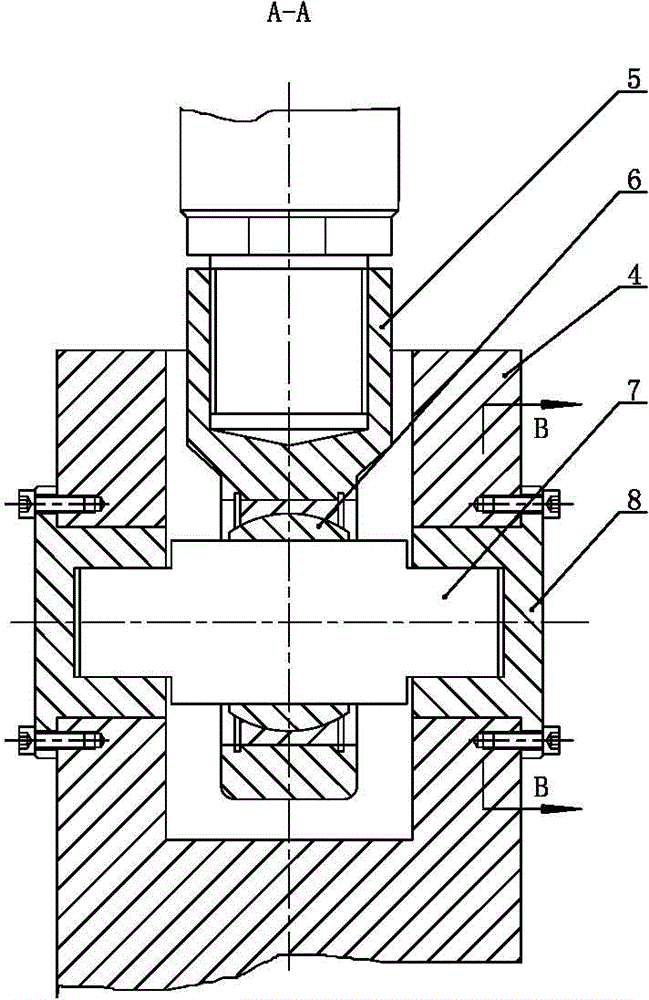

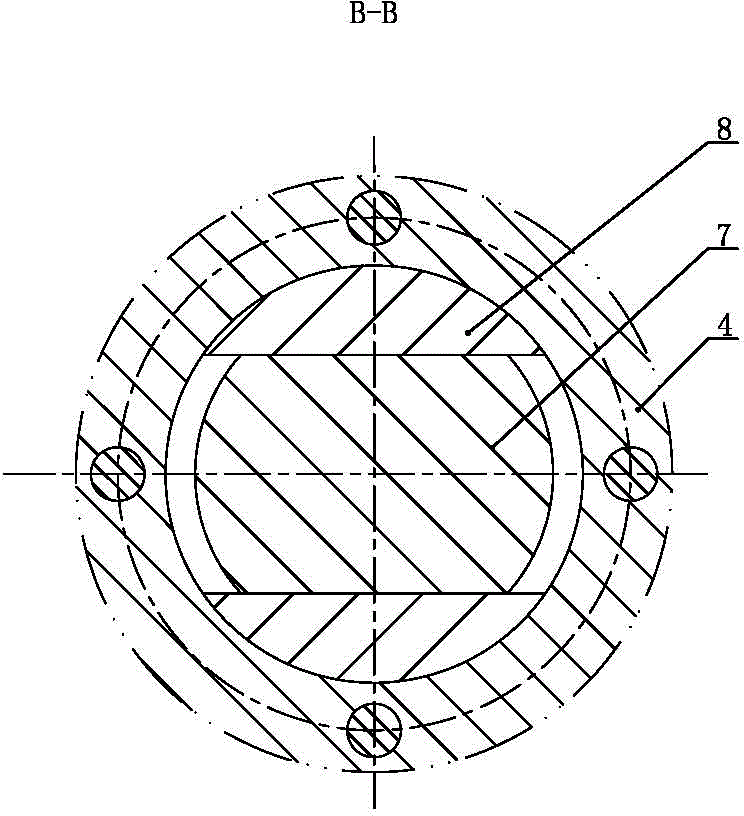

[0023] like Figure 1 to Figure 3 As shown, the gate type shearing machine of the present invention includes a bed 1, a material supporting mechanism and a shearing mechanism, and the shearing mechanism includes a left oil cylinder 2, a right oil cylinder 3 and a knife rest 4, and the left end of the knife rest 4 is connected to the left oil cylinder 2 The lower end of the piston rod, the right end of the tool holder 4 is connected to the lower end of the piston rod of the right oil cylinder 3, the cylinder bodies of the left oil cylinder 2 and the right oil cylinder 3 are respectively fixed on the bed 1, and the lower ends of the piston rods of the left oil cylinder 2 and the right oil cylinder 3 are respectively Connecting rod 5 is threadedly connected, and the lower end of connecting rod 5 is provided with connecting rod hole respectively, and the axis of connecting rod hole is perpendicular to the axis of piston rod and perpendicular to the plane where tool rest 4 is locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com