Method for calculating and testing difference of cuttingbehaviors of tool-workpiece interfaces of left and right cutting edges

A test method and cutting edge technology, applied in the direction of calculation, design optimization/simulation, special data processing application, etc., can solve the problem that there is no test method that can fully reveal the difference of cutting behavior of large-pitch trapezoidal external thread cutting tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

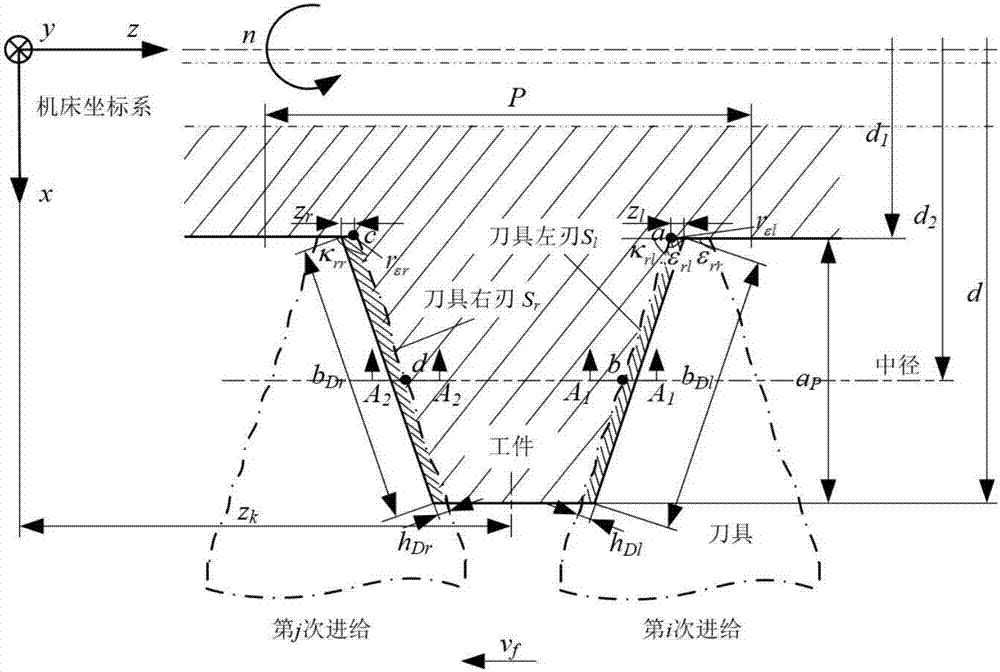

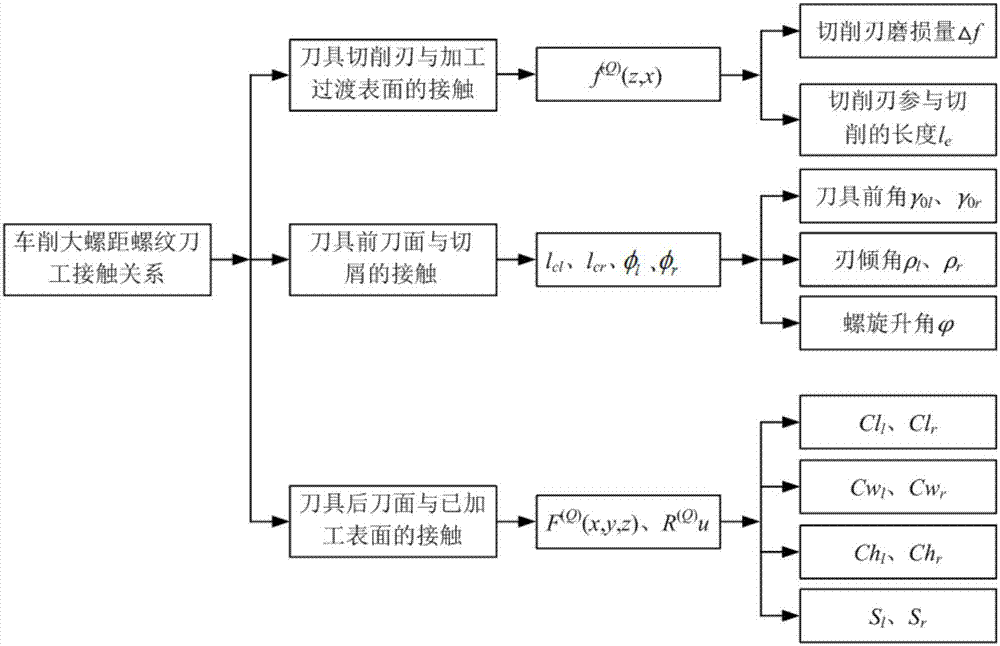

[0049] Implementation example 1: Hierarchical structure and characteristic variables of tool-worker contact relationship in turning large-pitch thread

[0050] (1) When the left and right edges of the large pitch thread are cut, because the working angle of the tool is different from the marked angle, the total cutting force and cutting stroke of the left and right edges of the tool are different, which will lead to inconsistent machining results of the left and right edges . During the initial cutting, the motion parameter variables of the left and right cutting edges of the tool are shown in Table 1.

[0051] Table 1 The basic variables of the relationship between the cutting motion of the left and right blades of the tool

[0052]

[0053] table, n l is the cutting speed of the left edge, n r is the cutting speed of the right edge, v cl is the main movement speed of the left blade, v cr is the main movement speed of the right blade, v fl is the feed speed of the le...

Embodiment 2

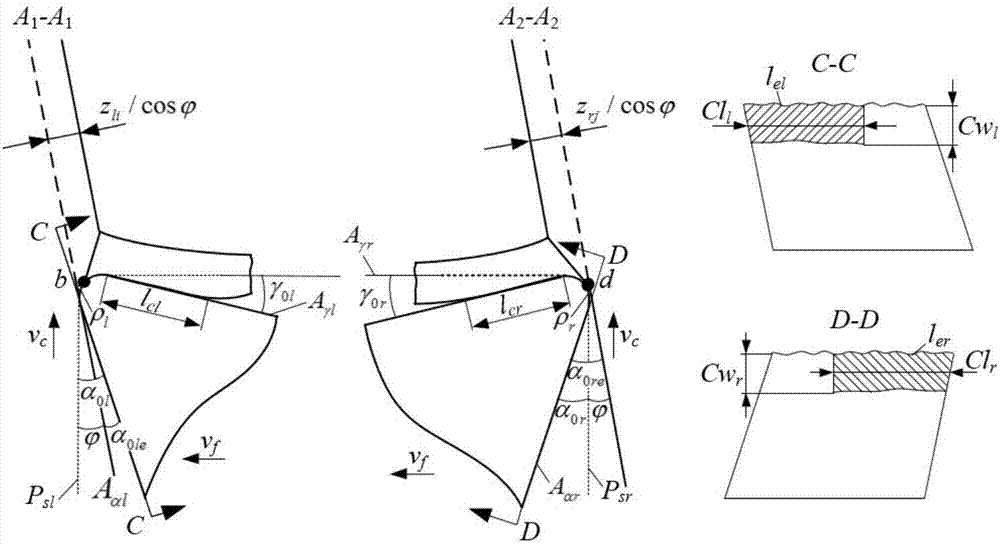

[0087] Implementation Example 2: Calculation method of the left and right knife contact length and knife contact width

[0088] Since the cutting edge and flank of the tool are severely worn during the process of cutting large-pitch threads, the tool-tool contact relationship can be characterized by the attitude of the cutting edge and the state of the flank during each period of cutting.

[0089] According to the initial state of the cutting edge of the tool, take the tool tip as the origin, and follow the right-handed Cartesian coordinate system to establish a rectangular coordinate system composed of x, y, and z axes, where the x direction is the direction of the radial feed speed of the tool, The y direction is the cutting speed direction, and the z direction is the tool axial feed direction. The curve equation F of the left and right edges of the tool in the tool coordinate system can be obtained by Matlab curve fitting l (0) (Z,X) and F r (0) (Z, X), apply coordinate...

Embodiment 3

[0111] Implementation example 3: force model of left and right edge cutting tools

[0112] When the left and right edges of the tool cut large-pitch threads, there are two sources of cutting force: one is the resistance produced by the elastic deformation and plastic deformation of the metal in the cutting layer, chips and the metal on the surface of the workpiece; Frictional resistance between surfaces. When using a forming turning tool to turn a large pitch thread, the force state of the tool is different when the left edge is turned and the right edge is turned. The specific force state is as follows Figure 7 , Figure 8 shown.

[0113] In the figure, F γl , F γr are the frictional forces acting on the rake face of the left and right cutting edges respectively, F αl , F αr are the frictional resistance acting on the flanks of the left and right cutting edges, respectively, F γNl , F αNl are the normal forces acting on the front and flank faces of the left cutting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com