Double-pump plate shearing machine and control method thereof

A shearing machine, oil pump motor technology, applied in shearing devices, shearing machine equipment, manufacturing tools and other directions, can solve the problems of insufficient shear angle adjustment accuracy, poor shear straightness, insufficient automation, etc., to achieve convenient processing, The effect of improved machining accuracy and fast transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

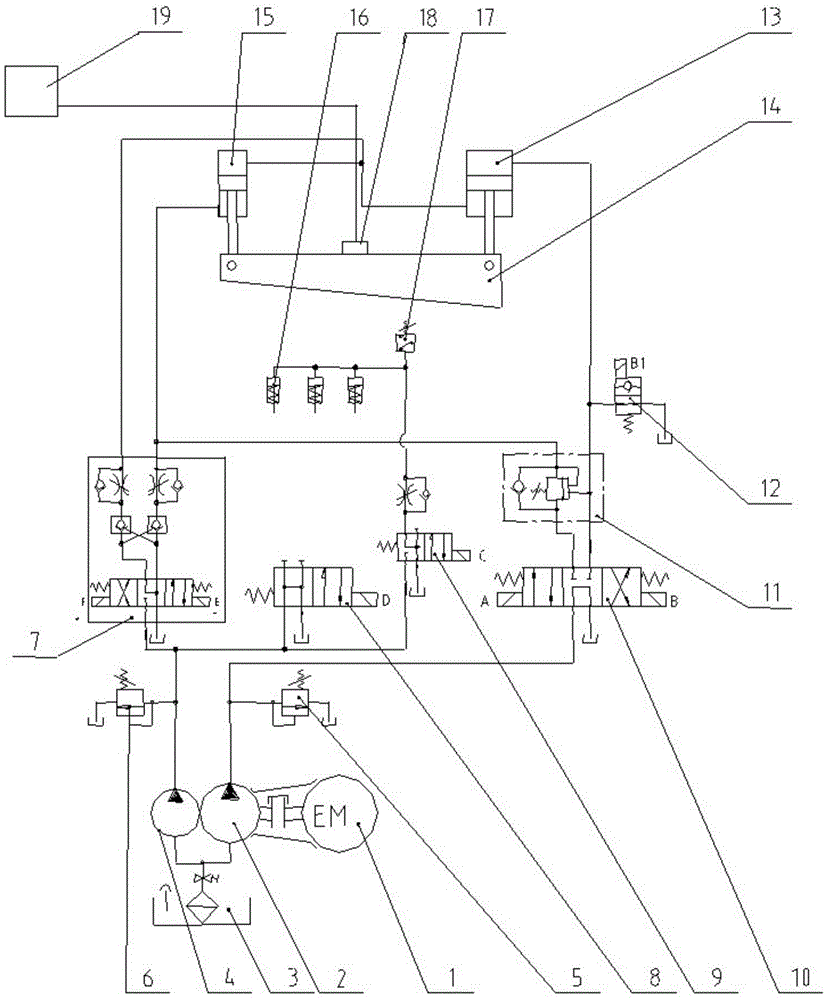

Embodiment 1

[0049] combine figure 1 , a double-pump shearing machine system, comprising a tool rest 14, an oil pump motor 1, a main oil pump 2, an oil tank 3, a main oil cylinder 13, an auxiliary oil cylinder 15, a pressing oil cylinder 16 and a pressure switch 17, on the said knife rest 14 An inclination sensor 18 is provided, which is connected to an external control system 19 . The inclination sensor 18 of this program is used for the level measurement of the system. The inclination sensor 18 can be divided into three kinds of inclination sensors of "solid pendulum" type, "liquid pendulum" type and "gas pendulum" from the working principle. The inclination sensor 18 can also be used to measure the change in inclination relative to the horizontal plane. The inclination sensor 18 of this program is arranged on the top surface of the knife rest 14, and the top surface of the knife rest 14 is a horizontal surface, and the center of the top surface is set;

[0050] The geometric accuracy ...

Embodiment 2

[0064] combine figure 1 , a double-pump shearing machine system, comprising a tool rest 14, an oil pump motor 1, a main oil pump 2, an oil tank 3, a main oil cylinder 13, an auxiliary oil cylinder 15, a pressing oil cylinder 16 and a pressure switch 17, on the said knife rest 14 An inclination sensor 18 is provided, which is connected to an external control system 19 . The inclination sensor 18 of this program is used for the level measurement of the system. The inclination sensor 18 can be divided into three types of inclination sensors of "solid pendulum" type, "liquid pendulum" type and "gas pendulum" from the working principle. The inclination sensor 18 can also be used to measure the change in inclination relative to the horizontal plane. The inclination sensor 18 of this program is arranged on the top surface of the knife rest 14, and the top surface of the knife rest 14 is a horizontal surface, and the center of the top surface is set;

[0065]The oil pump motor 1 is ...

Embodiment 3

[0076] Claim 3 is basically the same as claim 1, the difference lies in the control method;

[0077] A control method for a double-pump shearing machine, the steps are as follows:

[0078] (A) start the plate shearing machine system, start the plate shearing machine system, and the control system 19 starts to receive the inclination angle information of the inclination sensor 18, the main oil pump 2 and the pressure information of the pressure material oil pump 4;

[0079] (B) By receiving the oil pump information, the main oil pump 2 and the pressing oil pump 4 in this state are set as the initial state, and the cutting angle between the cutting edge of the shear knife and the horizontal direction is 2°, the control system 19, through the inclination sensor 18 The inclination angle X calculates the actual cutting angle between the knife edge and the horizontal direction at this time; at this time, the X value is 0.5°, and the actual cutting angle is 2.5°

[0080] (D) Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com