Control method for dynamic shearing displacements of flying shear of hot continuous rolling mill

A technology of hot continuous rolling mill and control method, which is applied in the direction of computer control, program control, shearing device, etc., can solve the problems of affecting rolling stability, shearing waste, and reducing yield, and achieve high-precision shearing control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

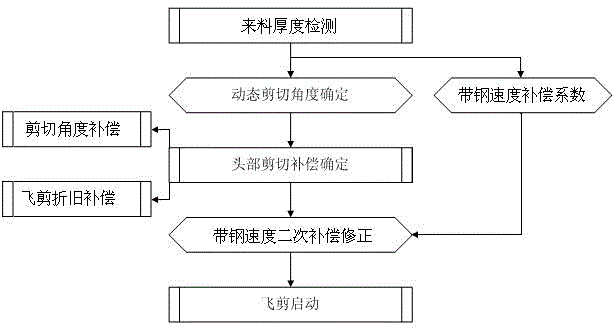

[0036] Such as image 3 Described, a kind of hot rolling mill flying shear dynamic shear amount control method, comprises the following steps:

[0037] S1: Set the standard roll speed V 0 , the initial shear length of the head L 0 , and the strip thickness T is obtained by measurement;

[0038] Standard roll speed V 0 The value is selected according to the characteristics of the rolling mill, usually the speed is less than 3m / s;

[0039] Head initial cut length L 0 Controlled by the process machine or set by experience;

[0040] The thickness T of the strip steel is obtained through the actual measurement of the position sensor of the oil cylinder of the water cutting roller. The oil cylinder of the water cutting roller is equipped with a position sensor. At this time, the water cutting roller will be in close contact with the strip steel, so the value displayed by the water cutting roller position sensor is the actual thickness value of the strip steel.

[0041] S2: Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com