Shape memory alloy fiber and super-elastic body compound deformation skin

A technology of memory alloy and superelastic body, which is applied in the aviation field, can solve the problems of insufficient deformation performance and single function of deformed skin, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

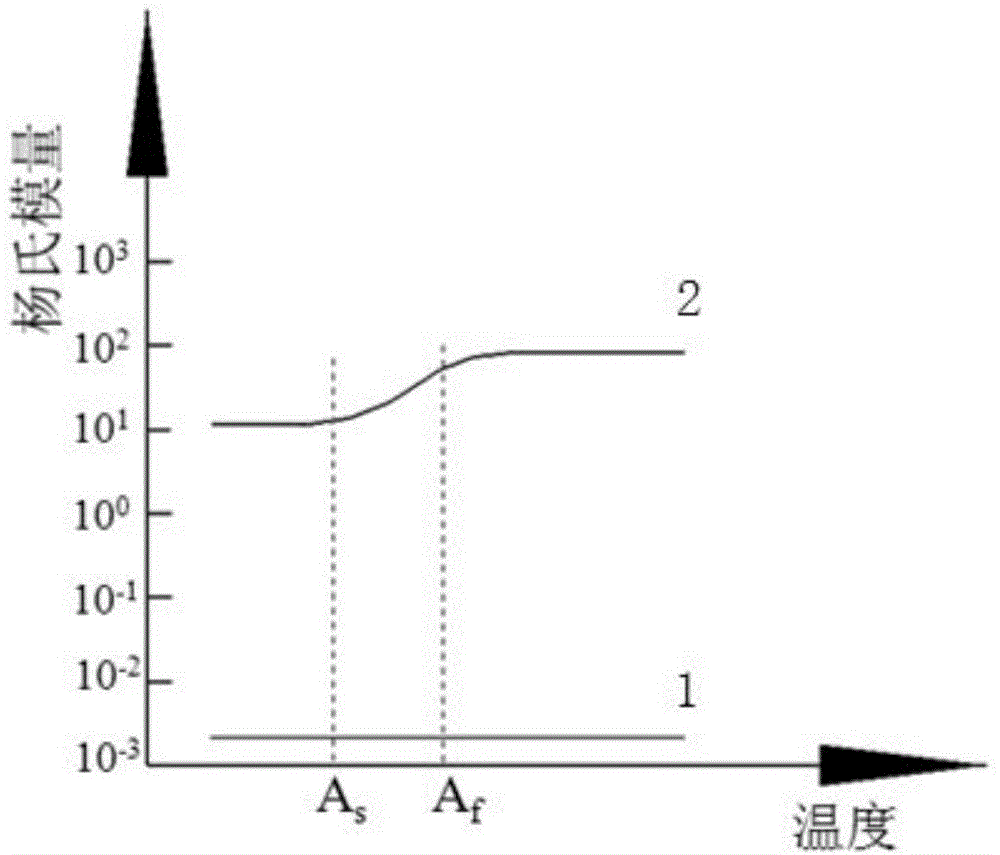

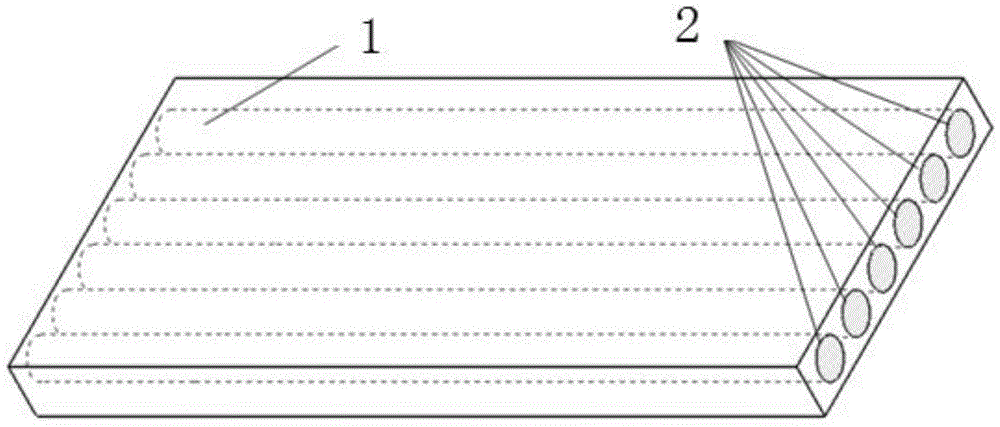

[0014] Specific Embodiment 1: In this embodiment, the shape memory alloy fiber and superelastic composite deformed skin is composed of a superelastic matrix 1 and a shape memory alloy fiber 2, and the shape memory alloy fiber 2 is solidified and arranged in parallel in the superelastic matrix 1 .

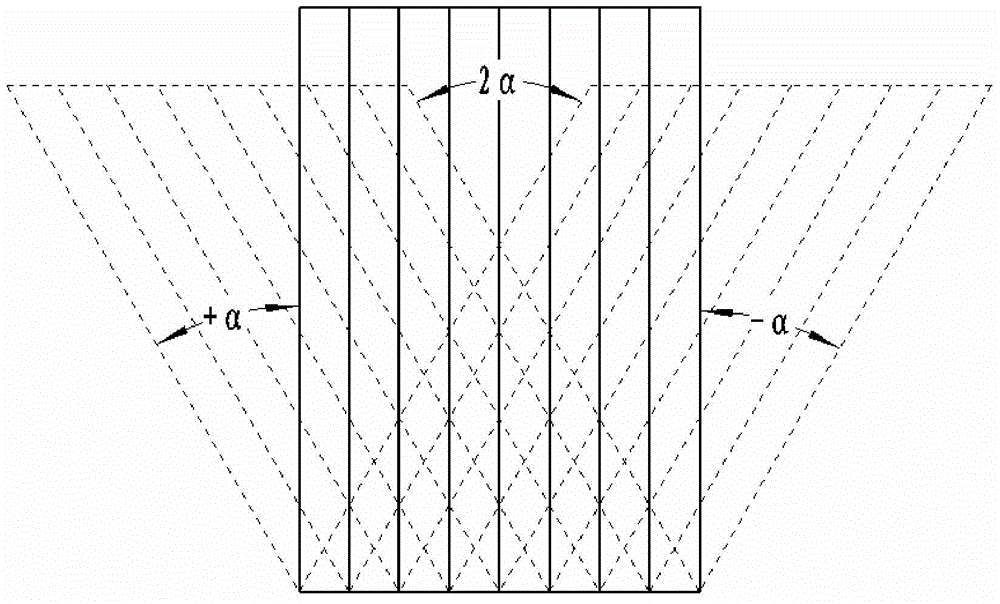

[0015] In this embodiment, when the shape memory alloy is in the martensitic phase, the out-of-plane deformation of the multifunctional deformable skin is driven by the action of the driver. The shape memory alloy is then thermally excited, and this multifunctional deformable skin can quickly return to its original shape.

[0016] The multifunctional deformable skin of this embodiment has the following advantages:

[0017] 1. Regardless of whether the shape memory alloy fibers in the multifunctional deformable skin are in the martensite phase or the austenite phase, the composite multifunctional skin system exhibits good in-plane deformation performance.

[0018] 2. When the shape...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the superelastomer matrix 1 is a rubber-type hyperelastomer, a gel-type hyperelastomer or a polyurethane-type hyperelastomer. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the shape memory alloy fiber 2 is made of nickel-titanium shape memory alloy, copper-nickel shape memory alloy, copper-aluminum shape memory alloy, Copper-zinc alloys or iron-based shape memory alloys. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com