Pavement structure and testing device for bridge deck pavement bonding interface shearing-resistance characteristic

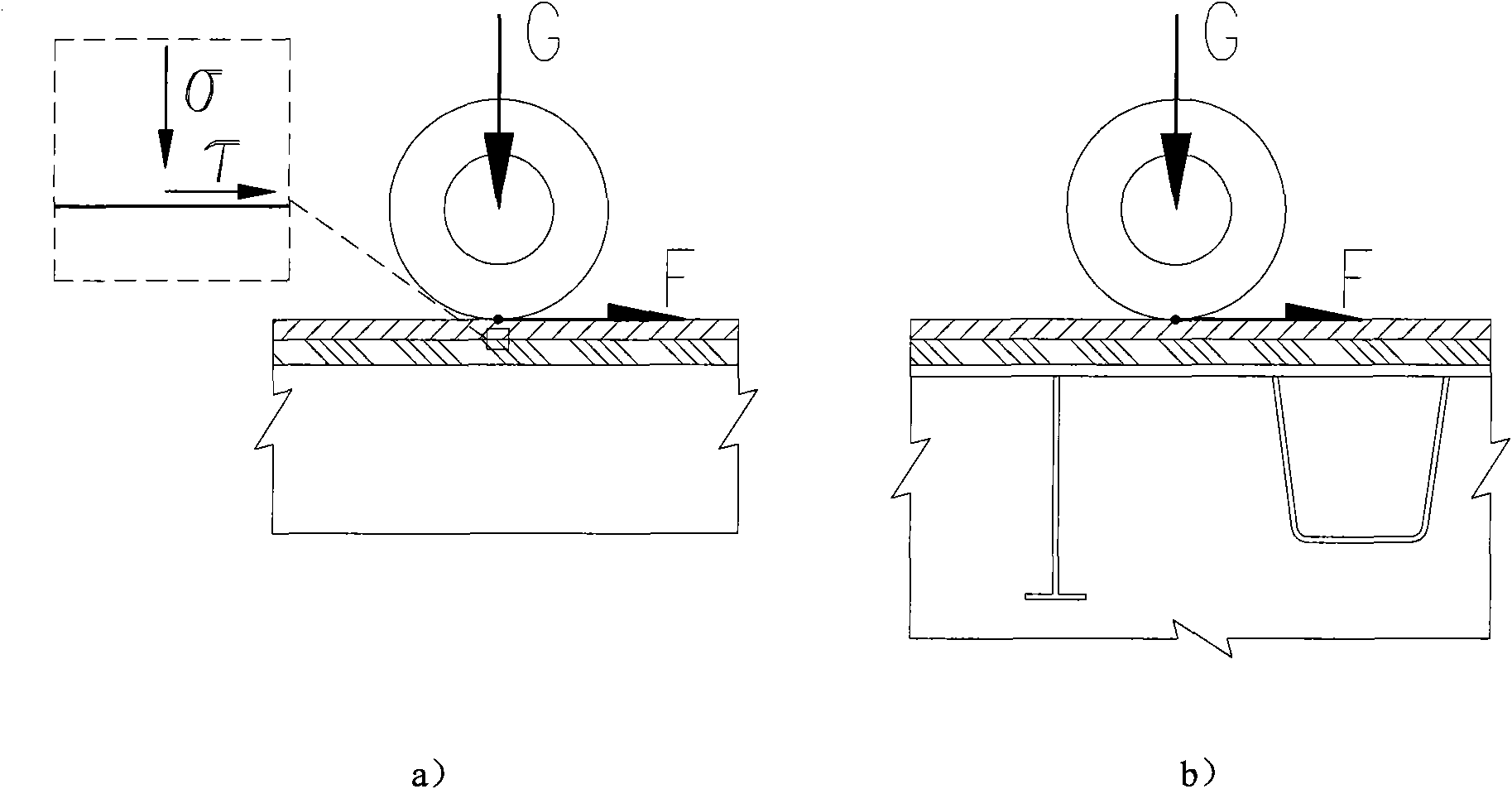

A technology for bridge deck pavement and pavement structure, which is applied in the direction of applying stable shear force to test the strength of materials, etc., which can solve the problem of inability to simulate engineering working conditions, the applicability of pavement or bridge deck pavement needs to be improved, and there is no unified testing equipment To achieve the effect of improving operational stability, overcoming the influence of bending moment, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Working steps using the test device:

[0028] A. Test piece production

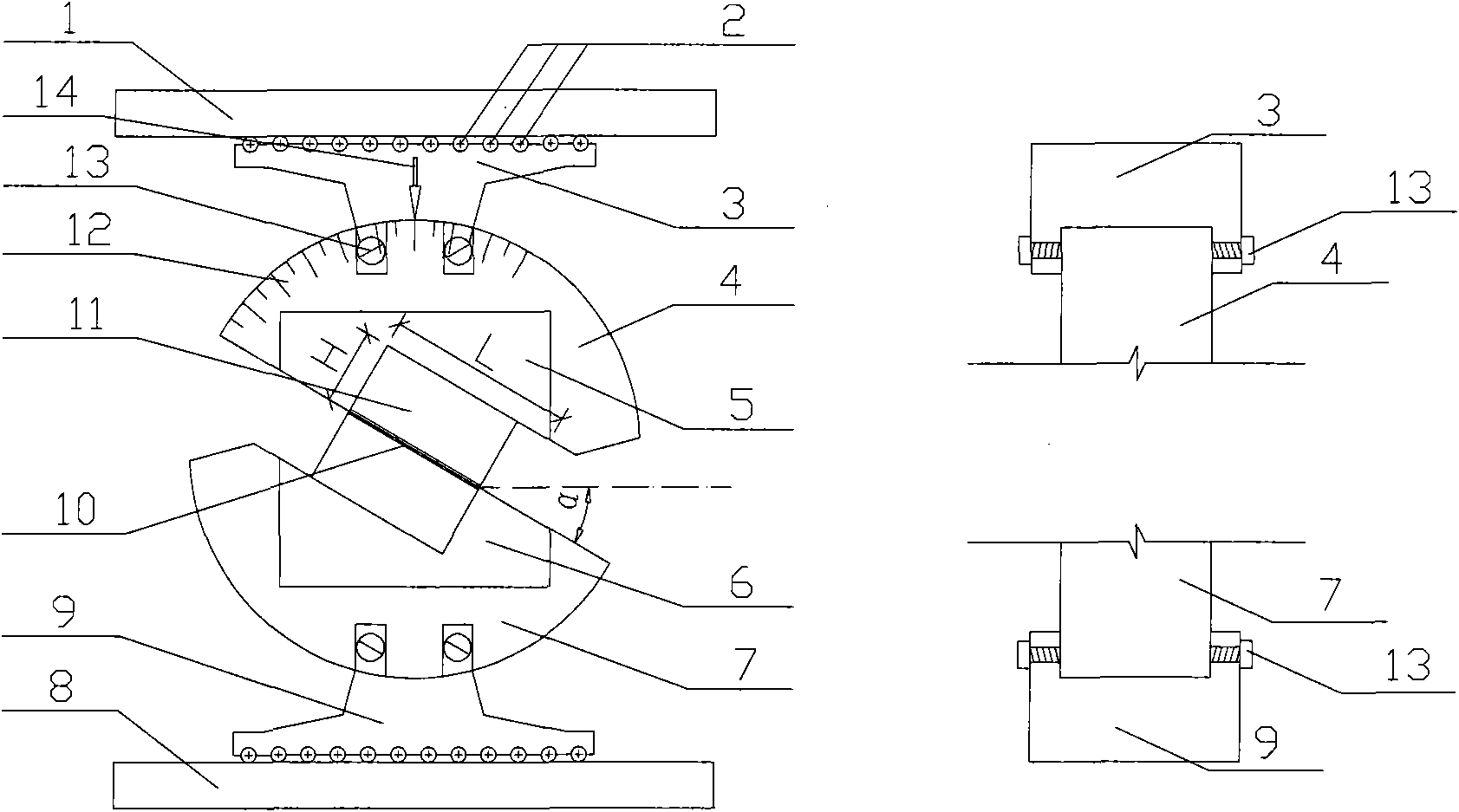

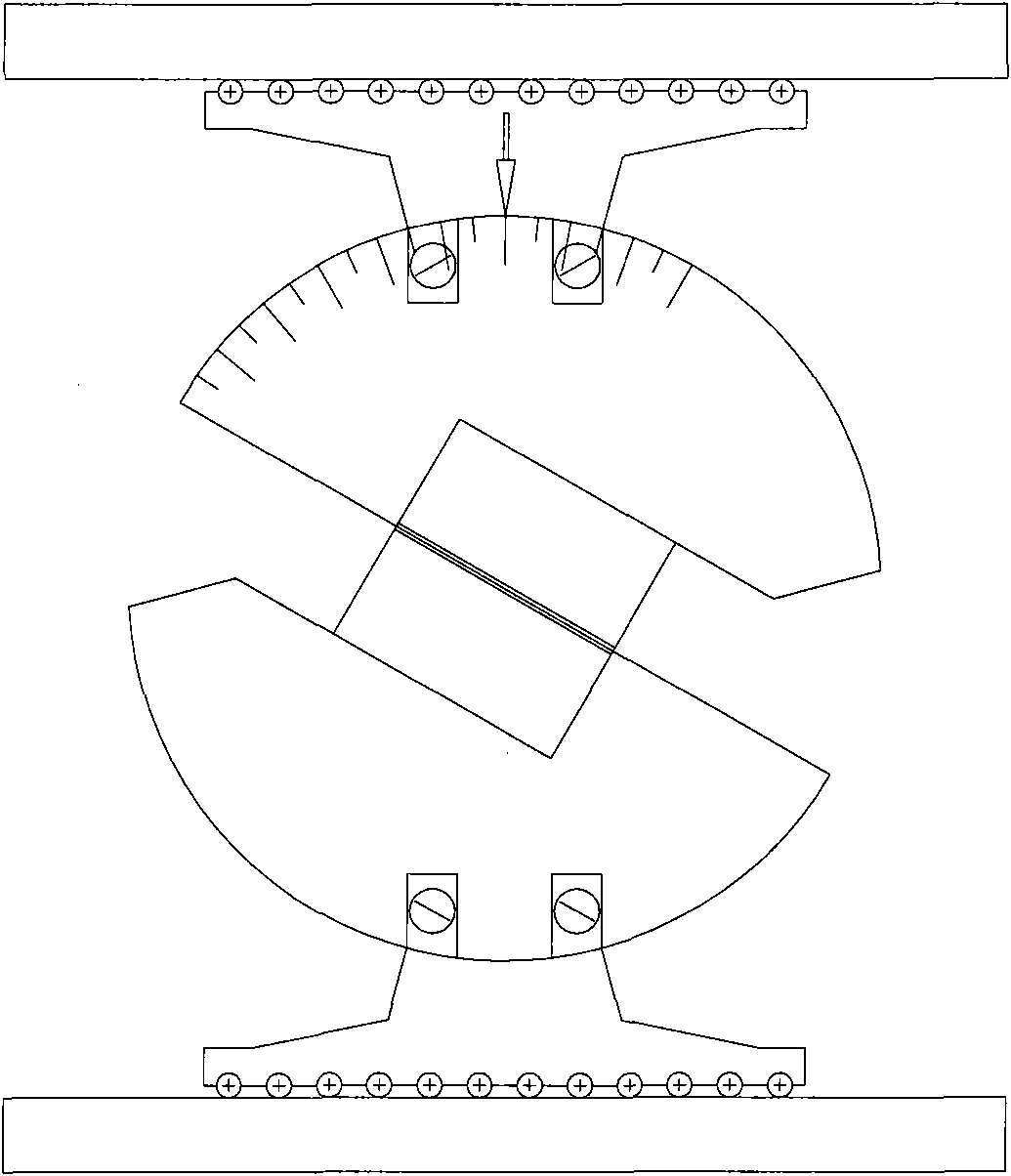

[0029] The test piece for testing the shear characteristics of the pavement can be made by rolling forming. First, lay the lower layer of the pavement in the test mold, then sprinkle the bonding material, and then lay the upper layer, and saw and cut it into a square composite test piece after cooling. 11. The middle is the bonding interface 10.

[0030] B. Test preparation

[0031] Place the prepared test piece in the groove of the internal chuck 5 and 6, turn the semicircular clamp 4 and 7 of the test device, make the pointer 14 point to the designated position on the dial 12, and then use the clamp fixing device 13 to The semicircular fixture (upper part) 4 is fixed to the upper arc-shaped base 3, and the semicircular fixture (lower part) 7 is fixed to the lower arc-shaped base 9 to ensure the stability of the device during the test. Adjust the position of the device so that the center of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com