Hydraulic brake-type numerical control shearing machine electric control system

An electrical control system and shearing machine technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of unable to meet the diversified needs of sheet metal processing, high operation requirements, single function, etc., and achieve high economic value and market prospects. , The effect of simplifying the electrical system and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

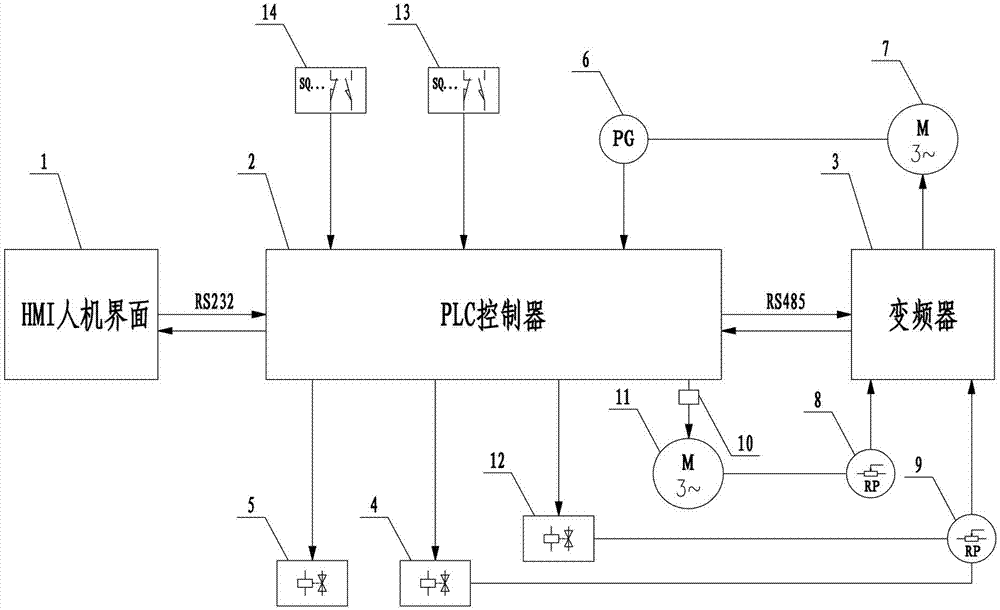

[0015] see figure 1 , the present invention includes HMI man-machine interface 1, PLC controller 2 and frequency converter 3;

[0016] The HMI man-machine interface 1 communicates with the PLC controller 2 through the RS232 communication cable, and the HMI man-machine interface 1 displays the current status of each moving part on the shearing machine in real time through the configuration interface, and accepts user data programming and input control instructions , to form a good human-computer interaction;

[0017] The PLC controller 2 collects in real time the switching signals of the knife rest position stroke switch group 13 and the pneumatic rear material support position stroke switch group 14, and sends control instructions to the downward solenoid valve 4 and the pneumatic rear material support solenoid valve 5 respectively, and the downward electromagnetic valve The valve 4 realizes the control of the position of the knife holder through the hydraulic oil circuit, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com