Passive and automatically pressurized mobile washing device for coal mine underground railway lane

A technology for flushing devices and tracks, which is applied in safety devices, mining equipment, earth-moving drilling, etc. to ensure cleanliness, reduce labor intensity, and improve labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

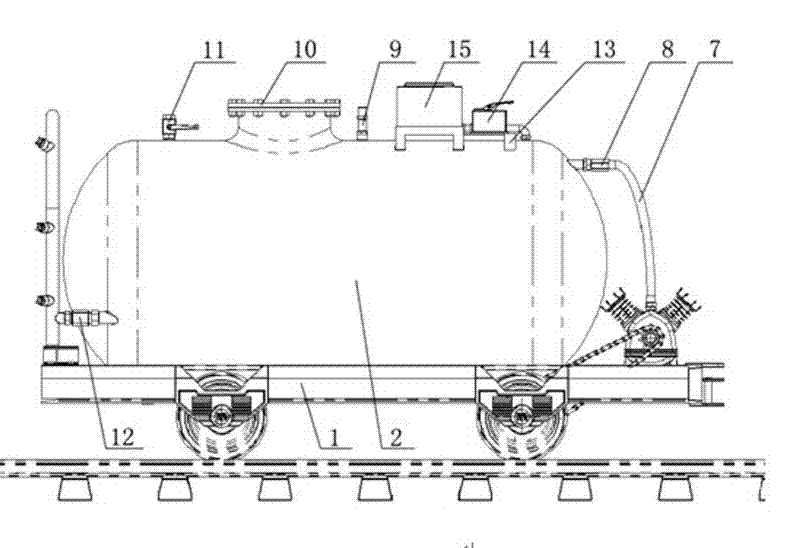

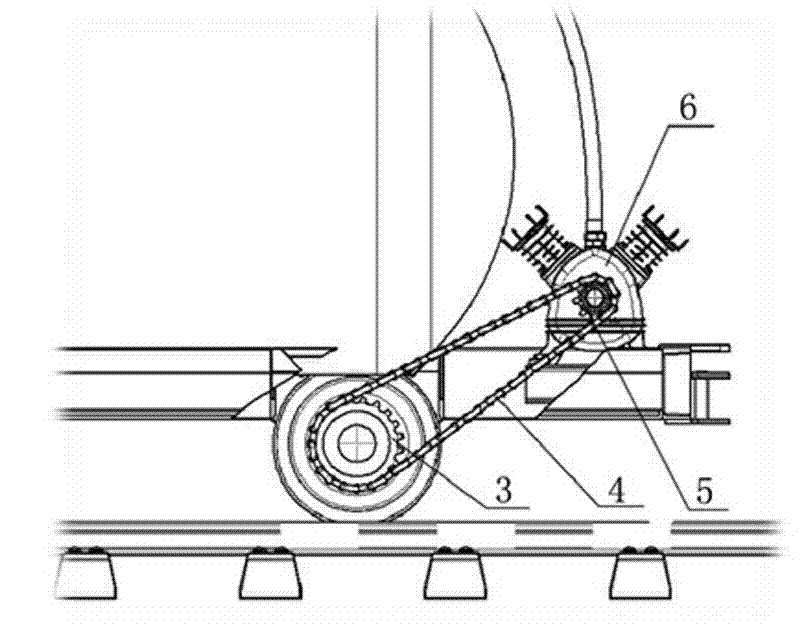

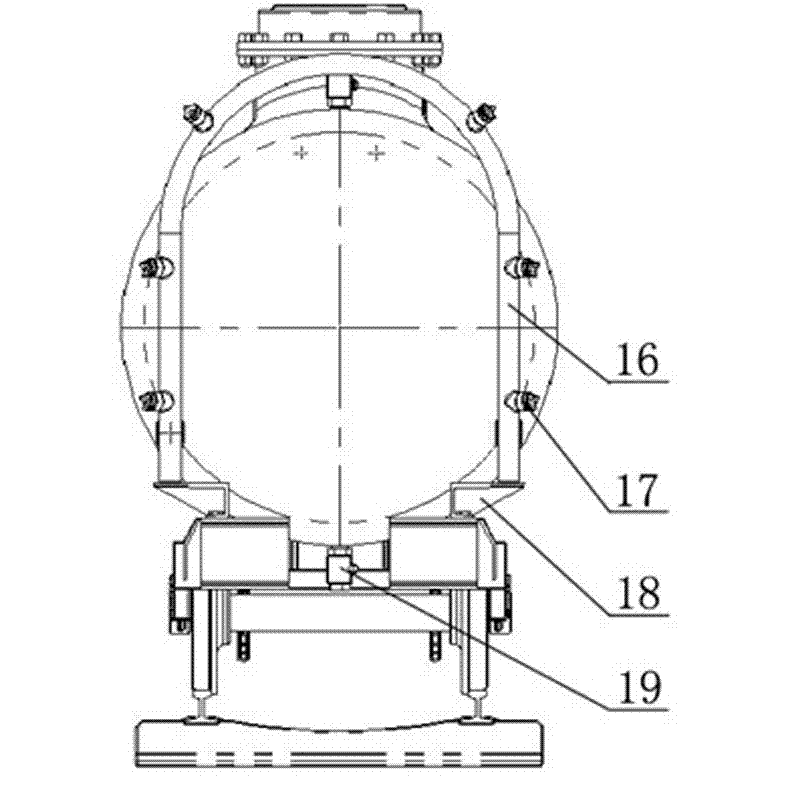

[0021] Such as Figure 1-3 As shown, implement a kind of passive pressurized mobile flushing device for underground track lane of coal mine, including cart 1, water storage tank 2, driving pulley 3, belt 4, driven pulley 5, air compressor 6, air intake pipe 7, single Directional valve 8, box support frame 13, hand pump 14, medicine box 15, liquid level gauge 9, water tank cover 10, exhaust valve 11, back pressure valve 12, drain valve 19, spray water pipe 16, spray nozzle 17 and The connecting frame 18 is composed of two air compressors connected by bolts on the cart, and the two check valves 8 are respectively connected with the air outlets of the air compressors 6 through the intake pipes, and the check valve 8 is connected with the water storage tank by threads. 2 The air inlets at the front end are connected. The main shaft of the air compressor 6 is connected with the driven pulley 5 through a key connection, and is locked by a shaft nut. Driven pulley 5 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com