Comprehensive test experiment device for dynamic and static properties of rolling bearing-main shaft system

An experimental device and comprehensive testing technology, applied in the direction of mechanical bearing testing, can solve the problem of single function, cannot verify the impact of bearing characteristics on the performance of the bearing-spindle system, and does not realize the impact of bearing characteristics. and other problems to achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

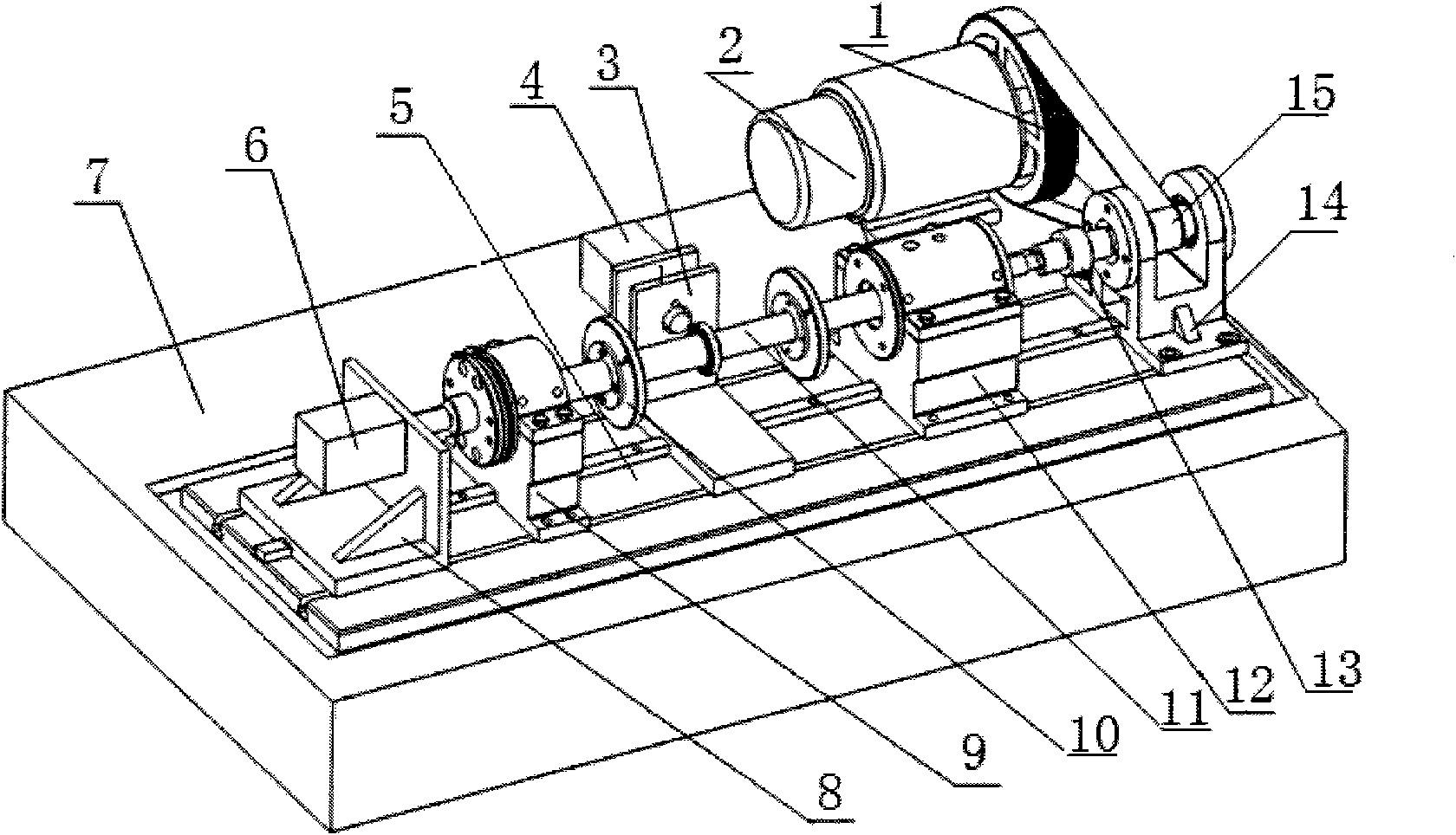

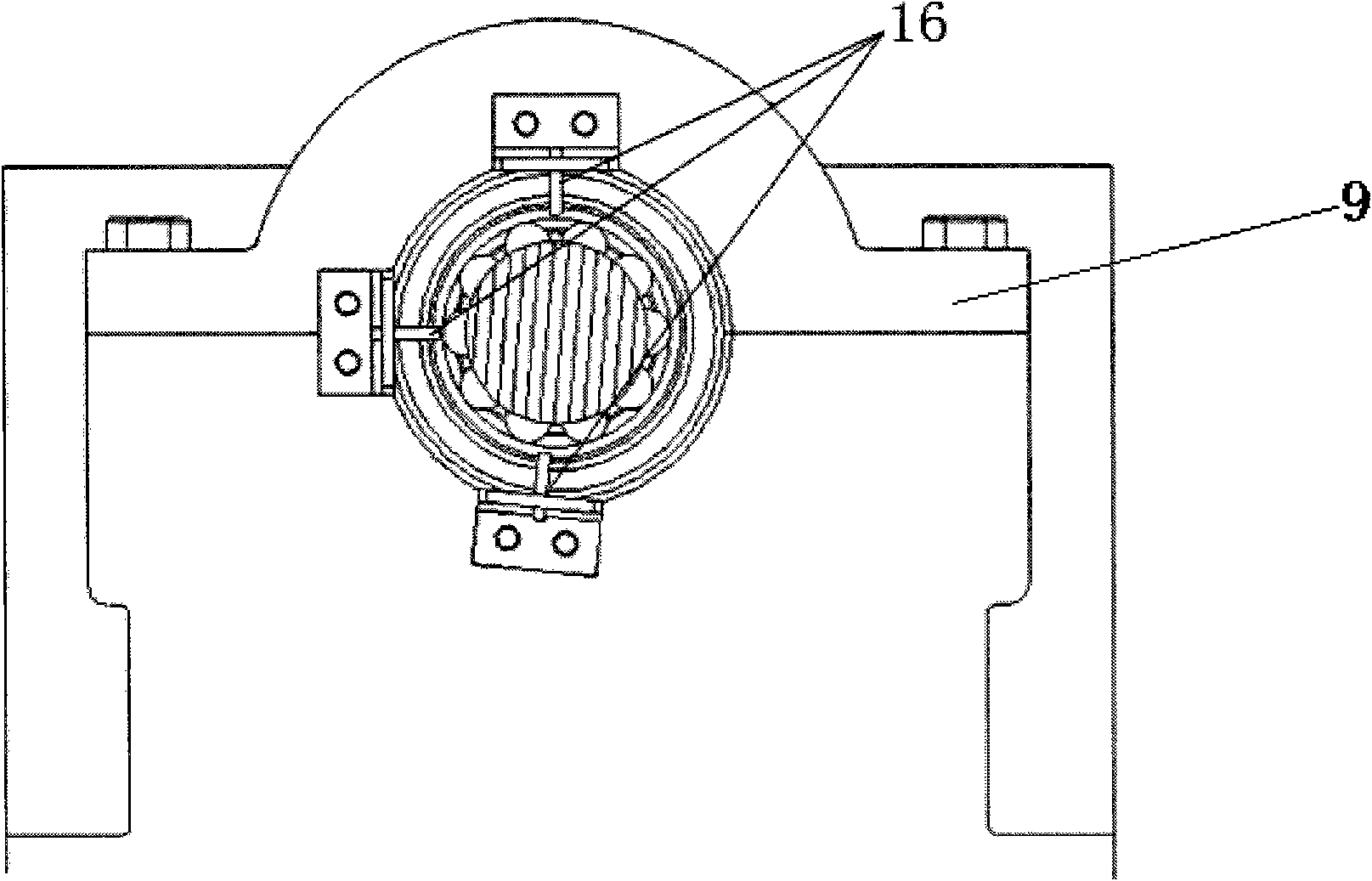

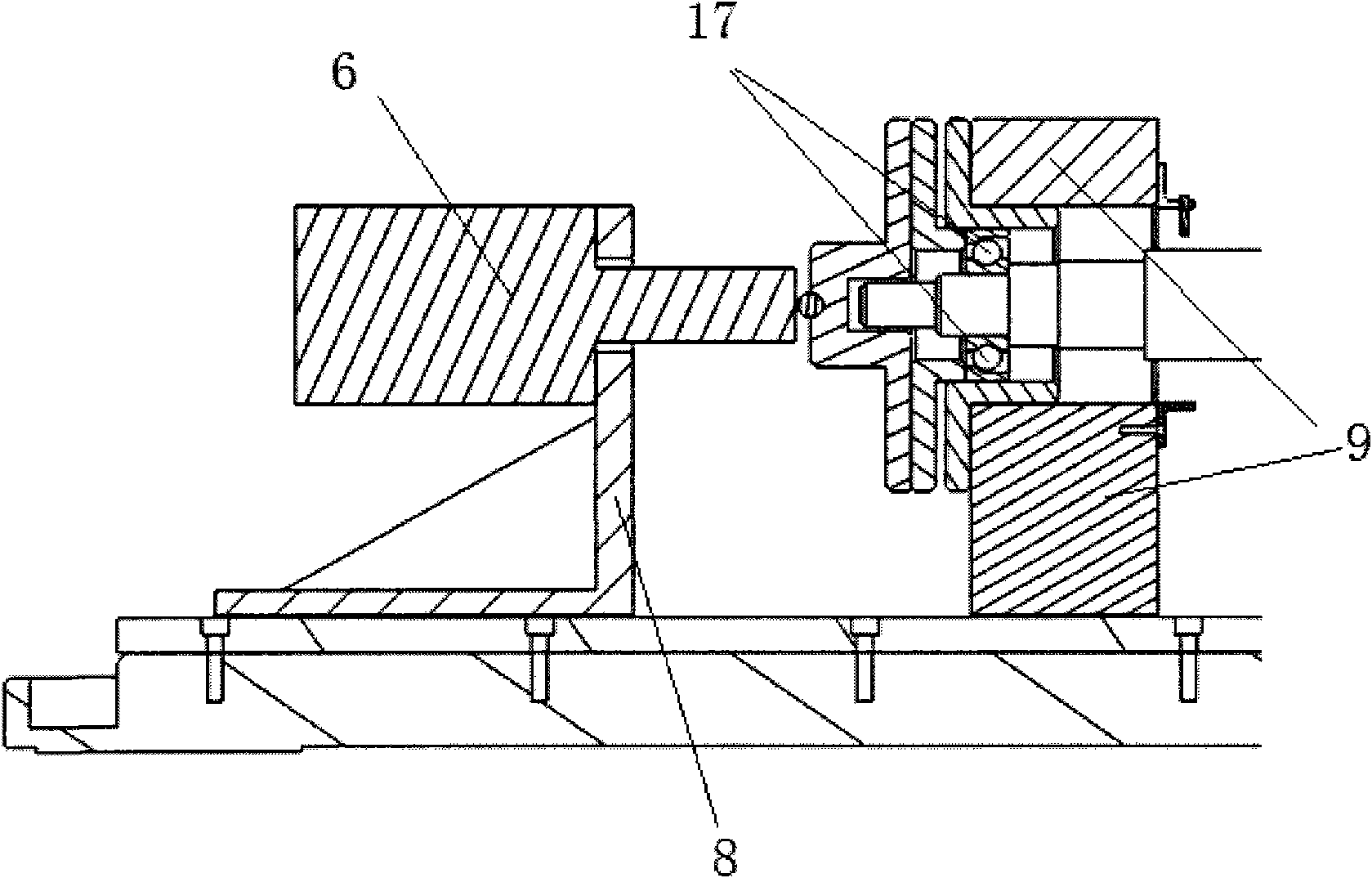

[0026] The experimental device for comprehensive testing of dynamic and static characteristics of rolling bearing-spindle system, refer to figure 1 , including the main shaft 11, the main shaft 11 is in the form of a stepped shaft, and its front end is installed on the front end bearing support 9, referring to figure 2 , three laser displacement sensor test probes 16 are installed on the end face of the front end bearing support 9, refer to image 3 , the test bearing 17 to be tested is installed on the front end bearing support 9, any model of the test bearing 17 can be adapted to the front end bearing support 9, the test bearing 17 is provided with a radial loading hydraulic cylinder 4 in the radial direction, and the axial An axial loading hydraulic cylinder 6 is arranged on the top, the radial loading hydraulic cylinder 4 is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com