Packing bag leakage detection device and method

A leakage detection and packaging bag technology, which is applied in transportation and packaging, testing fluid tightness by detecting the size change of the structural components to be tested, conveyor control devices, etc., can solve the problems of low detection accuracy and poor efficiency, and achieve detection High efficiency, small footprint and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

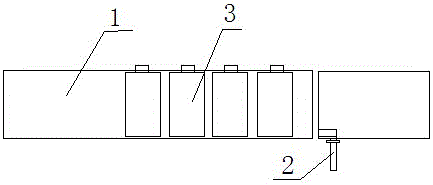

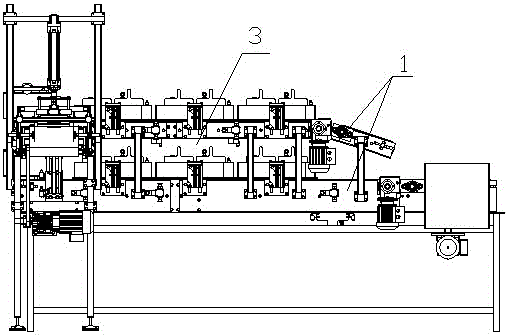

[0022] Packaging bag leakage detection equipment, the entire equipment is supported by a support frame, and also includes a conveyor belt 1, a rejecting mechanism 2, and a detection mechanism 3. Mechanism 2 is connected by a conveyor belt.

[0023] The conveyor belt 1 of the present invention is divided into upper and lower layers, the material inspection adopts the upper and lower separate lanes and throws the materials for conveying, and the discharging adopts the same conveying line for conveying.

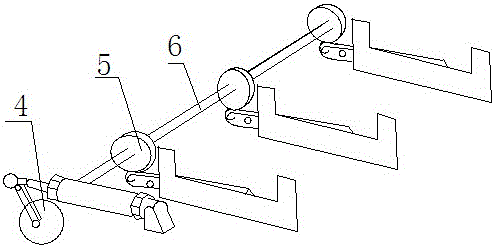

[0024] The detection mechanism of the present invention has at least one detection cavity and at least one stopper part, the stopper part is a ratchet cam, and each cam 4 is worn on the same shaft, and the ratchet 5 drives the shaft 6 and the cam 4 to realize rotation , The ratchet 5 is controlled by the cylinder, and the cylinder moves in sequence, and the ratchet 5 rotates 90 degrees.

[0025] The lower end of the detection chamber of the present invention is pressed against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com