Self-tightening sealing pressure test tool for high-pressure steel tube

A high-pressure steel pipe and self-tightening technology, which is applied in the direction of testing material strength by applying stable tension/pressure, testing fluid tightness by detecting dimensional changes of structural components to be tested, and using liquid/vacuum to measure liquid tightness, etc. , can solve problems such as inability to maintain pressure, low labor efficiency, and instability, and achieve the effects of easy production and operation, good sealing effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described in conjunction with the following examples.

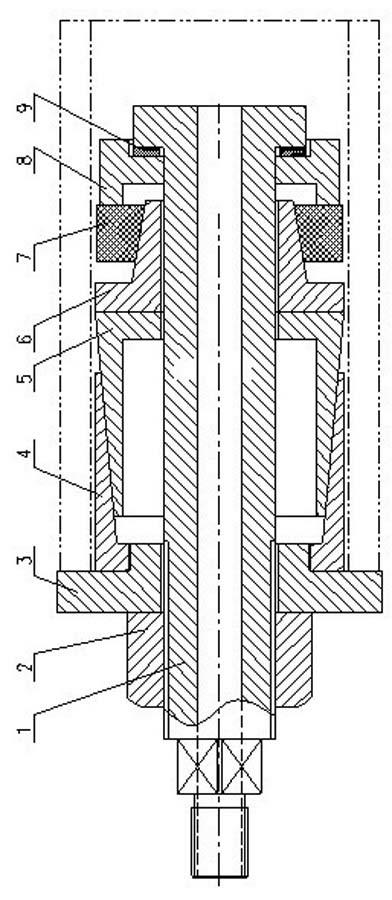

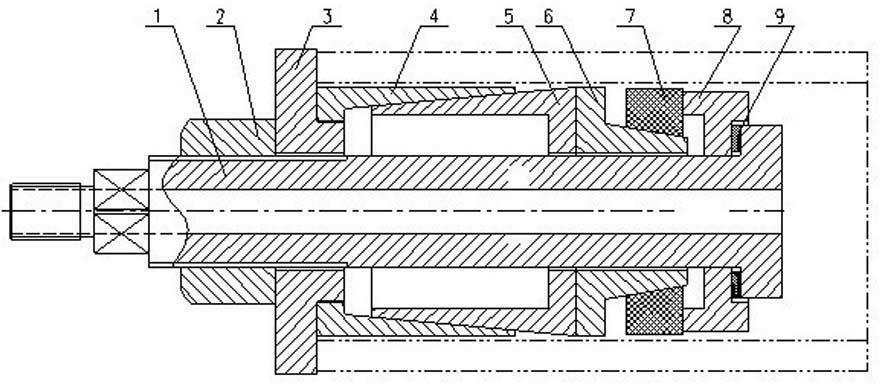

[0031] A specific embodiment of a self-tightening sealing pressure test tool for high-pressure steel pipes of the present invention includes a hollow tie rod 1, one end of the hollow tie rod 1 is provided with a water injection channel, and the other end of the hollow tie rod 1 is connected to the high-pressure The lumens of the steel pipes are connected, and the outside of the hollow tie rod 1 is provided with a nut 2, a top block 3, a first sealing assembly, a second sealing assembly and a gland 8 in sequence; the nut 2 is screwed to the hollow tie rod 1 , the inner end surface of the nut 2 abuts against the outer end surface of the top block 3, the outer peripheral side of the inner end surface of the top block 3 abuts against the end surface of the pipe head of the high-pressure steel pipe, and the inner end surface of the top block 3 The inner peripheral side of the first seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com