Fiber bragg grating sensing based hydraulic cylinder dynamic seal failure state monitoring method

A technology of optical fiber grating and failure state, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, testing fluid tightness by detecting the size change of the measured structural parts, etc., which can solve the problems of the influence of analysis results and achieve information transmission Large capacity, high precision and good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

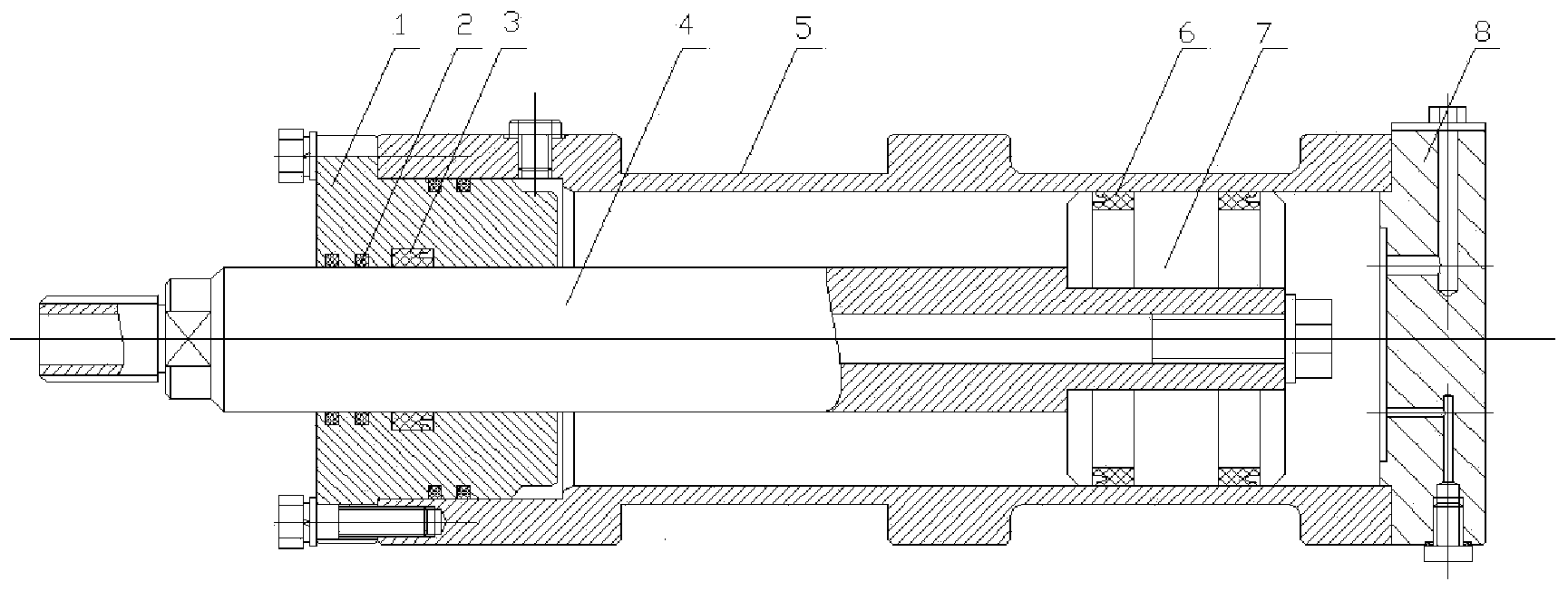

[0046] Example 1. Monitoring method for hydraulic cylinder dynamic seal failure status based on fiber grating sensing

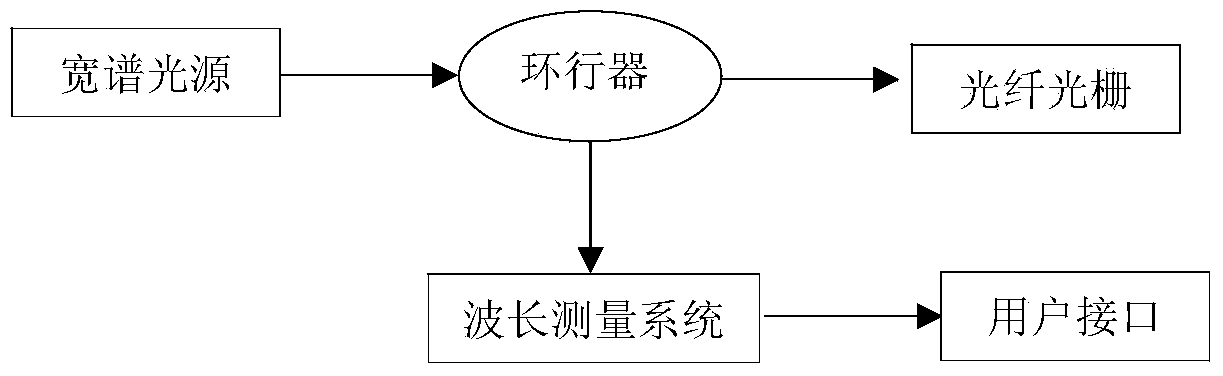

[0047] The method for monitoring the failure state of the hydraulic cylinder dynamic seal based on optical fiber grating sensing uses optical fiber sensing technology to monitor the failure state of the hydraulic cylinder dynamic seal in time, specifically: through the hydraulic cylinder piston rod and the piston dynamic seal groove Fiber grating strain sensors are laid on the bottom and sides, and fiber grating temperature sensors are laid inside the piston rod of the hydraulic cylinder to monitor the state changes of the dynamic seal in the hydraulic cylinder in time. The strain and temperature change data of the hydraulic cylinder are collected and analyzed in real time, and the failure state of the hydraulic cylinder dynamic seal is accurately judged by comparing the actual strain value of the working surface of the hydraulic cylinder dynamic seal with the...

Embodiment 2

[0119] Embodiment 2. Preparation of fiber grating strain sensor:

[0120] 1. The structure of the fiber grating strain sensor:

[0121] The fiber grating strain sensor, such as Figure 4 and Figure 5 As shown, it consists of four fiber grating strain sensors 702, 703, 102 and 103, wherein: the fiber grating strain sensor 702 and the fiber grating strain sensor 703 are located on the bottom and side surfaces of the hydraulic cylinder piston dynamic sealing groove to realize the hydraulic cylinder piston dynamic Sealing state monitoring: the fiber grating strain sensor 102 and the fiber grating strain sensor 103 are located on the bottom and side surfaces of the hydraulic cylinder piston rod dynamic seal groove to monitor the state of the hydraulic cylinder piston rod seal.

[0122] 2. Laying of the fiber grating strain sensor:

[0123]The following method is used to lay the fiber grating strain sensor: paste two fiber grating strain sensors 702 and 703 on the bottom and sid...

Embodiment 3

[0125] Embodiment 3. Preparation of fiber grating temperature sensor

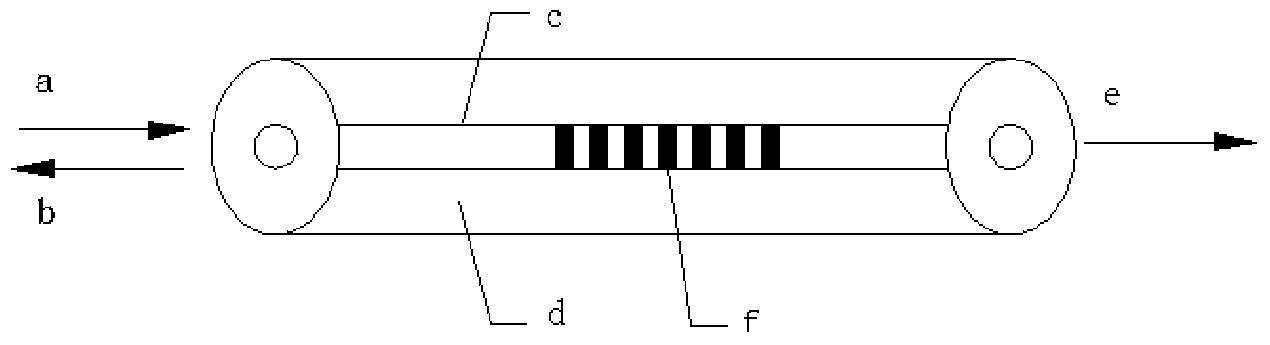

[0126] 1. The structure of fiber grating temperature sensor:

[0127] Described fiber grating temperature sensor (also known as fiber grating temperature sensor), such as Figure 6 As shown, it consists of a capillary steel pipe 10, a grating laying section 11 and an optical fiber lead-out part 9, wherein: the grating laying section 11 is in the middle of the capillary steel pipe 10 and is not affected by external force, so its wavelength change is only affected by temperature. Measure the temperature of the hydraulic cylinder during operation.

[0128] 2. Preparation of fiber grating temperature sensor:

[0129] The following method is used to prepare the fiber grating temperature sensor: coat a layer of high temperature resistant adhesive (J133 type epoxy resin) on the surface of the bare grating, that is, the fiber grating temperature sensor 11, and the thickness of the coating should be just enough to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com