Air leakage detection apparatus for gas packing food

A testing equipment and inflatable packaging technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as breeding bacteria, low efficiency, and difficulty in ensuring the accuracy of test results, and achieve continuous testing, efficiency improvement, and intuitive testing results. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

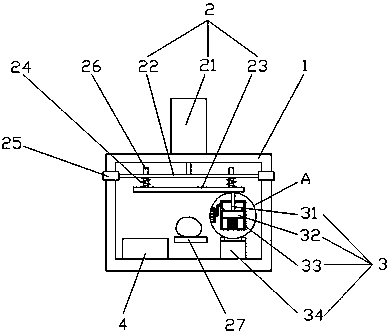

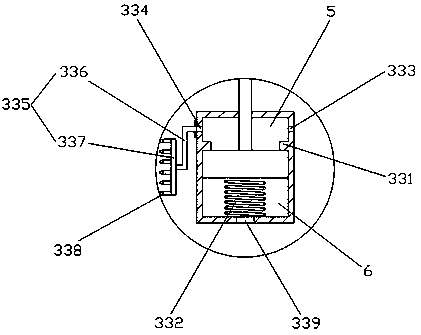

[0022] like Figure 1 to Figure 2 As shown in , an air leakage detection equipment for air-packed food includes a frame 1 , a pressing device 2 and a rejecting device 3 .

[0023] The pressing device includes an electric cylinder 21 fixed above the frame, a push rod 22 fixedly connected with the push rod of the electric cylinder and a pressing plate 23 located below the push rod, and a plurality of buffer springs 24 are connected between the pushing rod and the pressing plate. In the present invention, the electric cylinder drives the pressing plate downward to press the packaging bag. The electric cylinder can also be replaced by a similar device capable of realizing linear motion such as an air cylinder. The lower surface of the pressing plate is provided with a rubber layer to prevent the packaging bag from being scratched and affect the det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com