Deformation control method for large structure piece welding

A technology of large-scale structural parts and control methods, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as increasing production costs, prolonging production cycles, reducing product quality, and production efficiency, so as to reduce labor costs and improve Production efficiency, overcoming the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

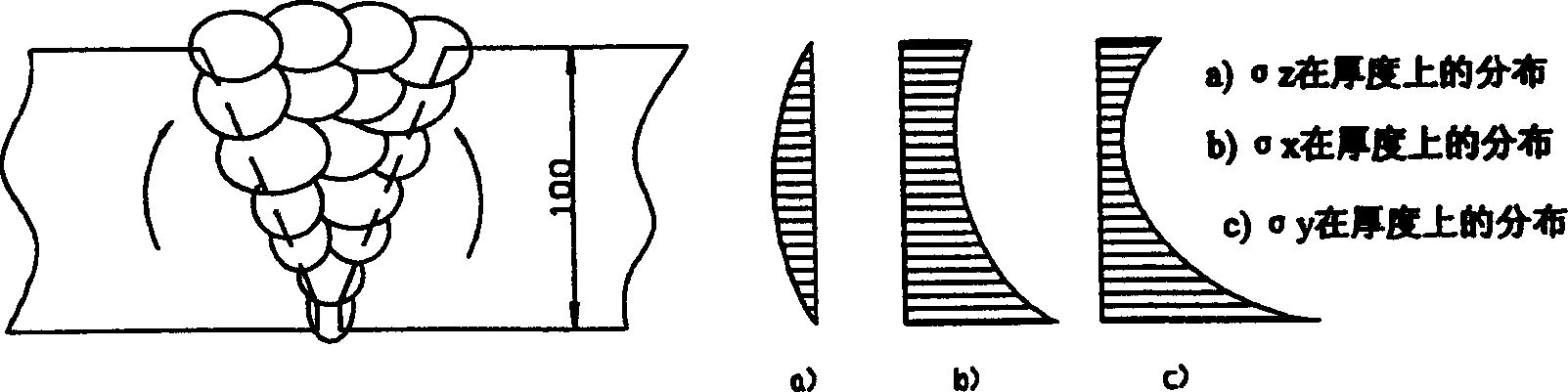

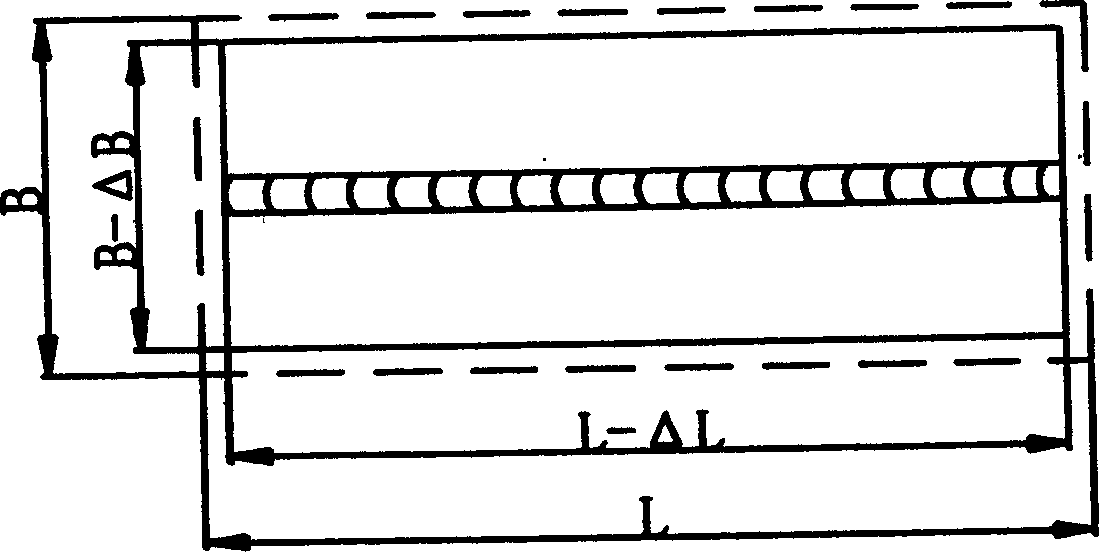

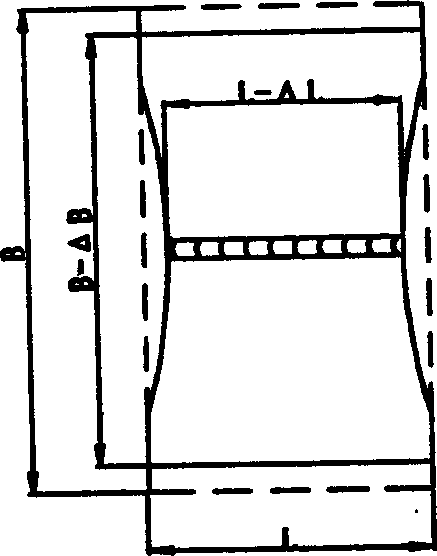

[0029] Firstly, the main factors and deformation types that cause welding deformation are introduced, see Figure 1 to Figure 5 .

[0030] 1. Influence of welding stress on deformation

[0031] The stress concentration of the welded structure changes greatly, and the shape of the weld and the layout of the weld will inevitably affect the distribution of stress, so that the stress concentration changes within a large range, which has a greater impact on welding deformation and cracks. Taking the stress distribution of multi-layer weld of low carbon steel plate as an example, the analysis is carried out.

[0032] Depend on figure 1 It can be seen that after welding, a large transverse tensile stress is generated at the root of the weld, and cracks are easily generated, and at the same time, large upward varicose deformation occurs.

[0033] 2. Influence of welding joint form on deformation

[0034] The structural design of the welded joint affects the stress state and thus h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com