Beam-rail integrated expansion device and design method for long-span railway steel bridge

A telescoping device and large-span technology, which is applied in the direction of railway fixing devices, bridge construction, bridges, etc., can solve problems such as the design method of telescopic devices with less beam ends, and achieve the effect of meeting the requirements of vertical support stiffness and reducing longitudinal telescopic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

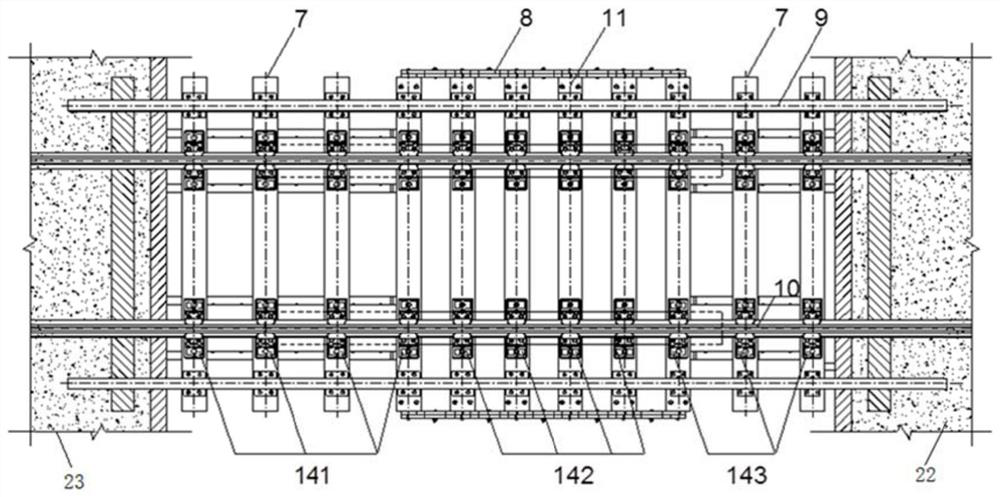

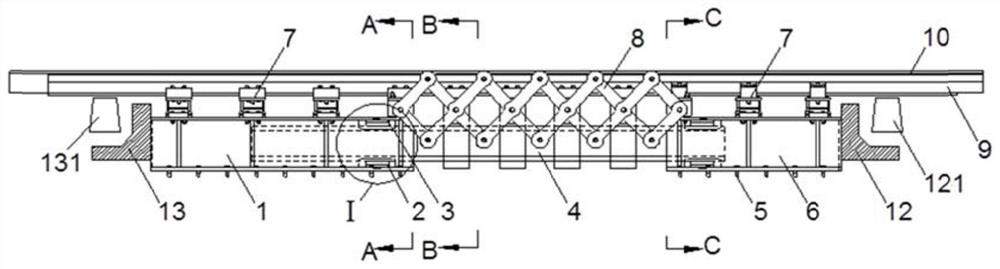

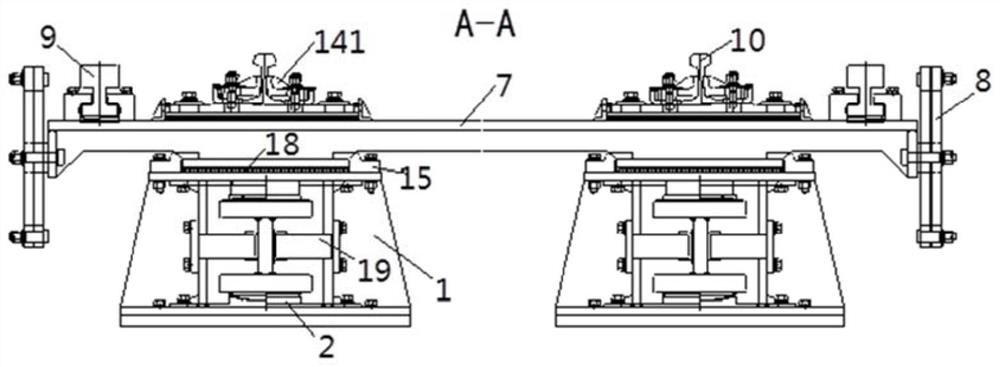

[0047]A beam-rail integrated telescopic device for a long-span railway steel bridge, comprising a movable end displacement box 1, a fixed end displacement box 6, a supporting beam 4, a fixed steel sleeper 7, a movable steel sleeper 11, a connecting rod system 8 and a lateral guide rail 9.

[0048] The movable end displacement box 1 is fixedly connected with the 23 ends of the approach bridge, and the fixed end displacement box 6 is fixedly connected with the main bridge 22 ends. The connection between the displacement box 6 and the pre-embedded steel plate on the side deck of the main bridge is realized by anchor bolts 5 . The movable end displacement box 1, the support beam 4 and the fixed end displacement box 6 are sequentially connected along the longitudinal direction of the railway steel bridge and jointly constitute the lower support structure of the beam-rail integrated telescopic device. 6 One end is fixed longitudinally, and the other end of the movable end displacem...

Embodiment 2

[0071] The invention provides a performance-based design method of a beam-rail integrated expansion device for a large-span railway steel bridge. The concept of beam-rail integration is used to design the telescopic device at the beam end.

[0072] Its specific technical process is as follows: Figure 5 as shown, Figure 5 The basic process of the performance-based design method of beam-rail integrated telescopic device is given in , including:

[0073] (1) Analyze the rationality of the existing bridge constraint system, and qualitatively propose a reasonable constraint system for the new bridge. By carrying out the beam end displacement analysis, the spatial displacement characteristics of the bridge beam end under different load conditions can be clarified. Specifically, the finite element model of the long-span railway steel bridge can be established, and the beam end can be analyzed under different load conditions. Displacement characteristics of end space; combined wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com