Laser cladding method of shaft and tube element

A laser cladding and cladding technology, which is applied in the direction of machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, surface polishing machine tools, etc. Low-level problems, to achieve the effect of simplifying machining procedures, improving cladding efficiency, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A laser cladding method for a column, the specific steps are as follows:

[0042] S1: Processing and testing before cladding. Machining the column, testing the original specification size, and leaving a machining allowance according to the technical requirements. The machining allowance is generally the diameter after cladding minus the diameter of the final product, and the machining allowance in this embodiment is not less than 0.2mm.

[0043] S2: Surface pretreatment, degreasing the column to ensure the bonding between the cladding layer and the substrate. Specifically, use alcohol to wipe and sandpaper to polish the area to be clad to remove rust, oil and dirt.

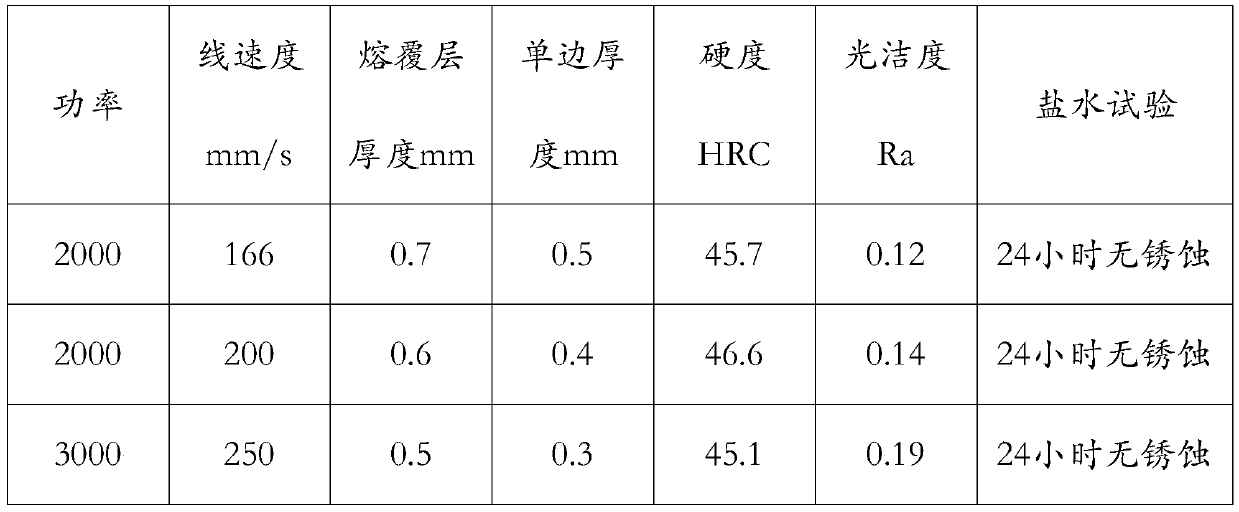

[0044] S3: Laser cladding. Place the column on the lathe, use elastic thimbles to clamp the column, and perform positioning and alignment. The laser processing system in this embodiment uses coaxial powder feeding. First, set the laser cladding parameters, including cladding power of 2000W and laser spo...

Embodiment 2

[0059] A laser cladding method for a mandrel, the specific steps are as follows:

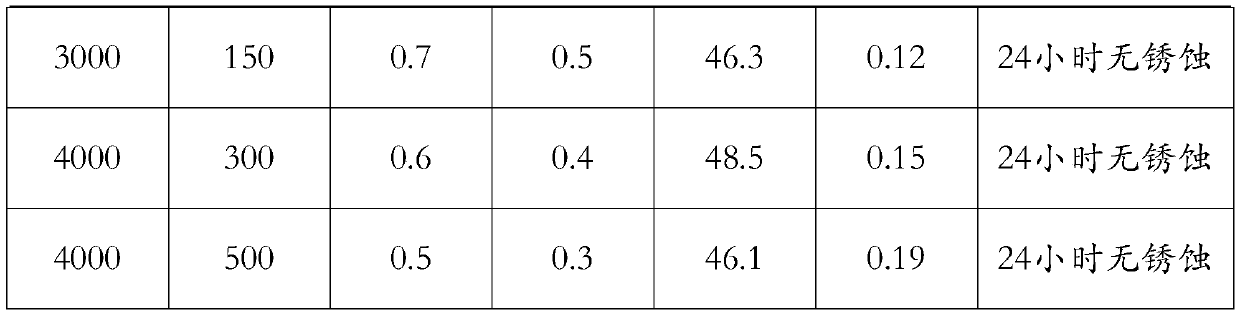

[0060] S1: Processing and testing before cladding. The cladding part is the overall outer surface of the mandrel, the diameter of the mandrel in the cladding area is Φ180.3mm, the length of the cladding area is 11m, and the cladding surface area is 6.3m 2 ; After confirming the state of the mandrel, straighten the workpiece, and the concentricity is ≤0.2mm; use a lathe to turn the surface of the mandrel. The turning process includes rough turning and fine turning. The speed is 40mm / min, the turning speed of the lathe is set at 150r / min, and the feed rate is 20mm / min, and the fatigue layer on the surface of the mandrel is removed by turning to obtain a surface roughness ≤ Ra6.3; finally, the flaw detection of the workpiece is carried out to check the surface of the mandrel Whether there are pores or crack defects, the next step can be performed only after the entire flaw detection is qualified. ...

Embodiment 3

[0073] A high-speed laser cladding method for boiler tubes, the specific steps are as follows:

[0074] S1: Processing and testing before cladding. Machining the boiler tubes, testing the original size, and leaving a machining allowance according to the technical requirements. The machining allowance is generally the diameter after cladding minus the diameter of the final product, and the machining allowance in this embodiment is not less than 0.2mm.

[0075] S2: Surface pretreatment, degreasing the workpiece to ensure the bonding between the cladding layer and the substrate. Specifically, use alcohol to wipe the area to be clad to remove rust, oil and dirt.

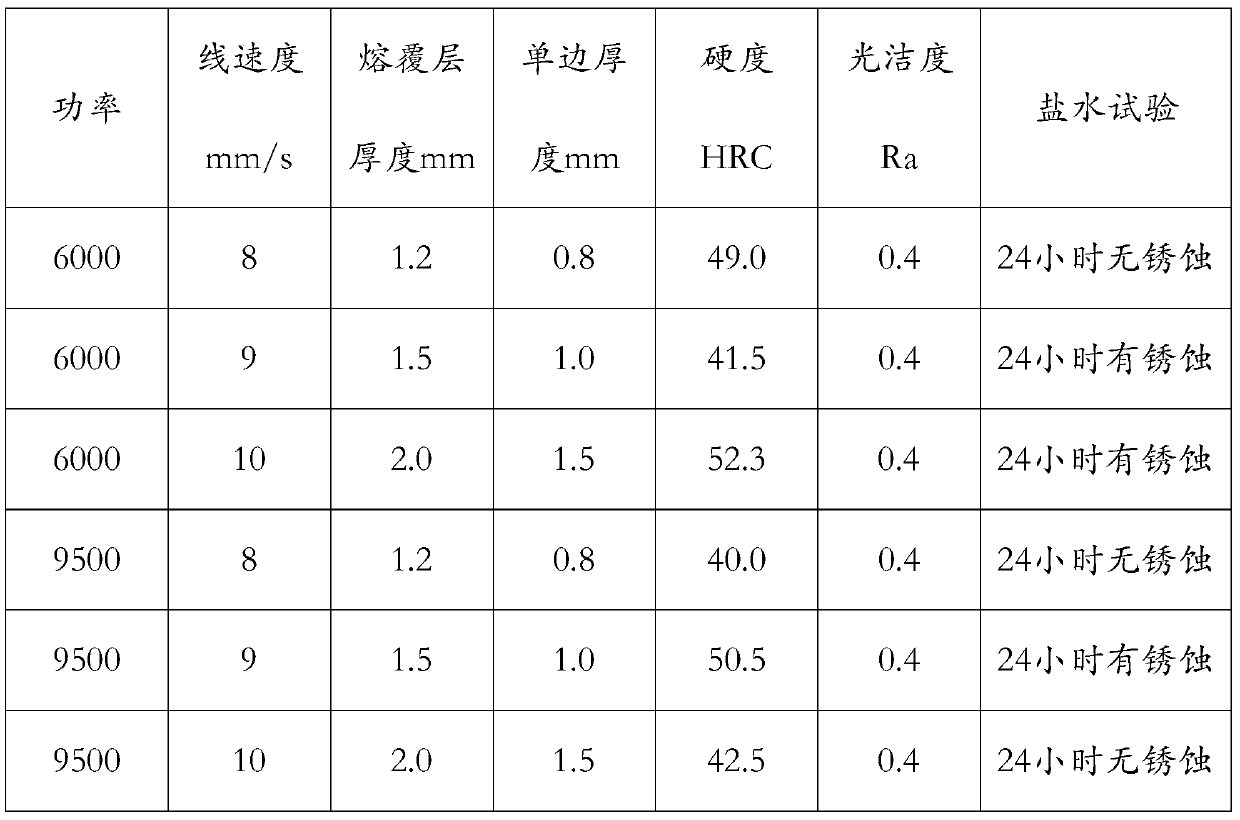

[0076] S3: Laser cladding. Firstly, the boiler tube to be processed is placed on the lathe, clamped with a positioner, and positioned and aligned; then the robot grabs the laser and advances along the axis of the boiler tube with a step distance of 0.5mm, and the positioner drives the boiler The tube realizes the rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentricity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com