Iron-based welding wire for laser cladding and preparation method thereof

A technology of iron-based welding wire and laser cladding, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problem of no welding wire, etc., and achieve the effects of low manufacturing cost, uniform composition and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

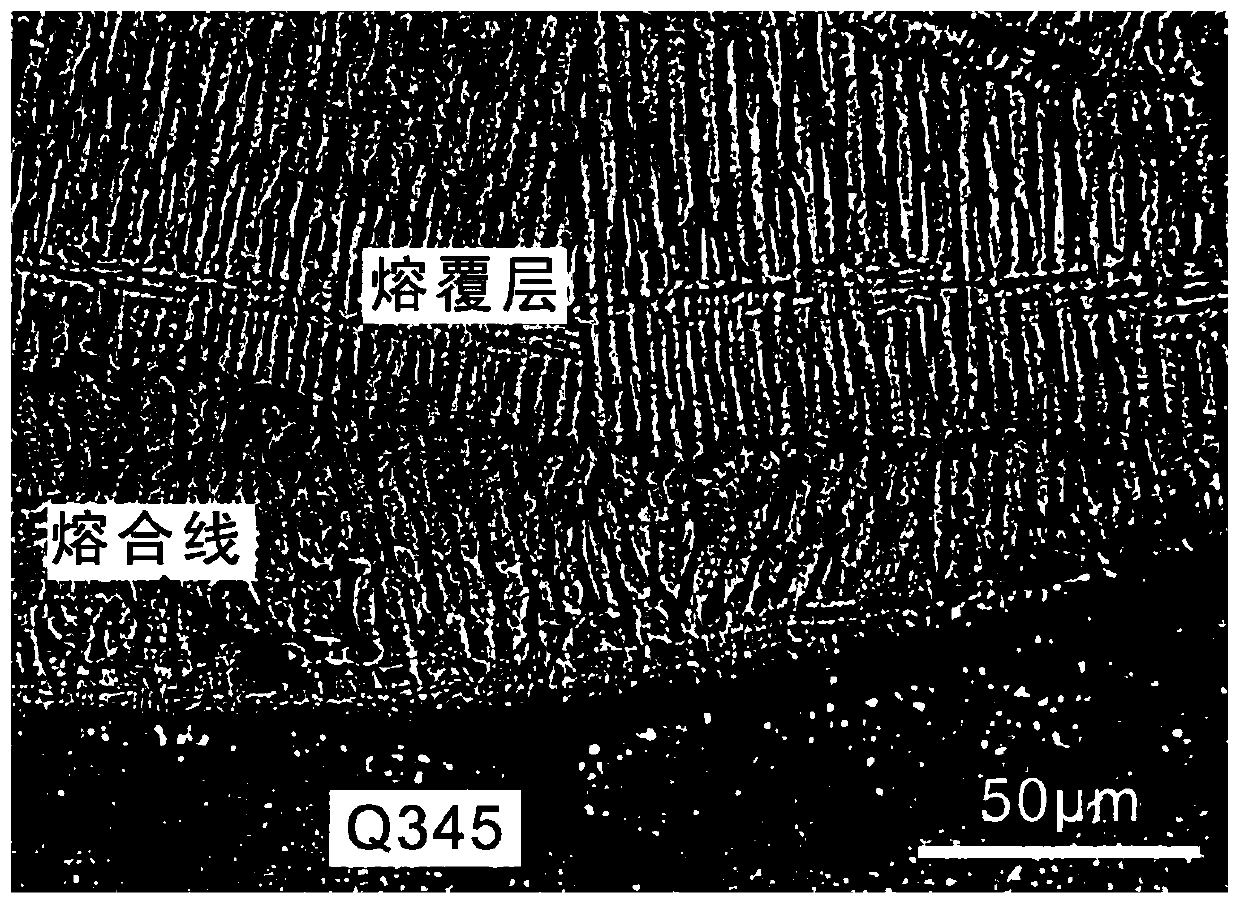

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned iron-based welding wire for laser cladding, the specific steps are as follows:

[0036] Step 1: Weigh the following powders according to mass percentage: B powder 1.7-6.5%, ferrosilicon powder 1.3-4.0%, ferromanganese powder 2.6-5.5%, Ni powder 10-24%, Cr powder 60-80%, more than The sum of the mass percentages of the components is 100%;

[0037] Step 2: Place B powder, ferrosilicon powder, ferromanganese powder, Ni powder and Cr powder weighed in step 1 in a vacuum heating furnace for heat treatment at a heating temperature of 260-300°C and a holding time of 2 hours. Crystal water in the medicinal powder; place the heat-treated B powder, ferrosilicon powder, ferromanganese powder, Ni powder and Cr powder in a powder mixer to fully mix to obtain a mixed medicinal powder, and the mixing time is 1h;

[0038] Step 3: Use alcohol to remove the grease on the surface of the low-carbon steel strip, and wrap the mixed drug powder p...

Embodiment 1

[0044] A preparation method of iron-based welding wire for laser cladding:

[0045] Step 1: Take the following medicinal powders by mass percentage: B powder 1.7%, ferrosilicon powder 1.3%, ferromanganese powder 2.6%, Ni powder 24%, Cr powder 70.4%, the sum of the above component mass percentages is 100%;

[0046] Step 2: Place the B powder, ferrosilicon powder, ferromanganese powder, Ni powder and Cr powder weighed in step 1 in a vacuum heating furnace for heat treatment at a heating temperature of 260°C and a holding time of 2 hours. crystal water; the heat-treated B powder, ferrosilicon powder, ferromanganese powder, Ni powder and Cr powder are placed in a powder mixer and fully mixed to obtain a mixed powder, and the mixing time is 1h;

[0047] Step 3: Use alcohol to remove the grease on the surface of the low-carbon steel strip, and wrap the mixed drug powder prepared in step 2 in the low-carbon steel strip through the flux-cored wire drawing equipment. The hole diameter ...

Embodiment 2

[0053] A preparation method of iron-based welding wire for laser cladding:

[0054] Step 1: Take the following medicinal powders by mass percentage: B powder 6.5%, ferrosilicon powder 4.0%, ferromanganese powder 5.5%, Ni powder 10%, Cr powder 74%, the sum of the mass percentages of the above components is 100%;

[0055] Step 2: Place the B powder, ferrosilicon powder, ferromanganese powder, Ni powder and Cr powder weighed in step 1 in a vacuum heating furnace for heat treatment at a heating temperature of 300°C and a holding time of 2 hours. crystal water; the heat-treated B powder, ferrosilicon powder, ferromanganese powder, Ni powder and Cr powder are placed in a powder mixer and fully mixed to obtain a mixed powder, and the mixing time is 1h;

[0056] Step 3: Use alcohol to remove the grease on the surface of the low-carbon steel strip, and wrap the mixed drug powder prepared in step 2 in the low-carbon steel strip through the flux-cored wire drawing equipment. The hole dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com