TIG (tungsten inert gas welding) power assistant double TIG (tungsten inert gas welding) compound heat source welding equipment and method

A composite heat source and welding equipment technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as unsatisfactory thermal conductivity of hot wire, limit the application of welding materials, destroy the welding wire feeding process, etc., to achieve convenient Promote, improve cladding efficiency, improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

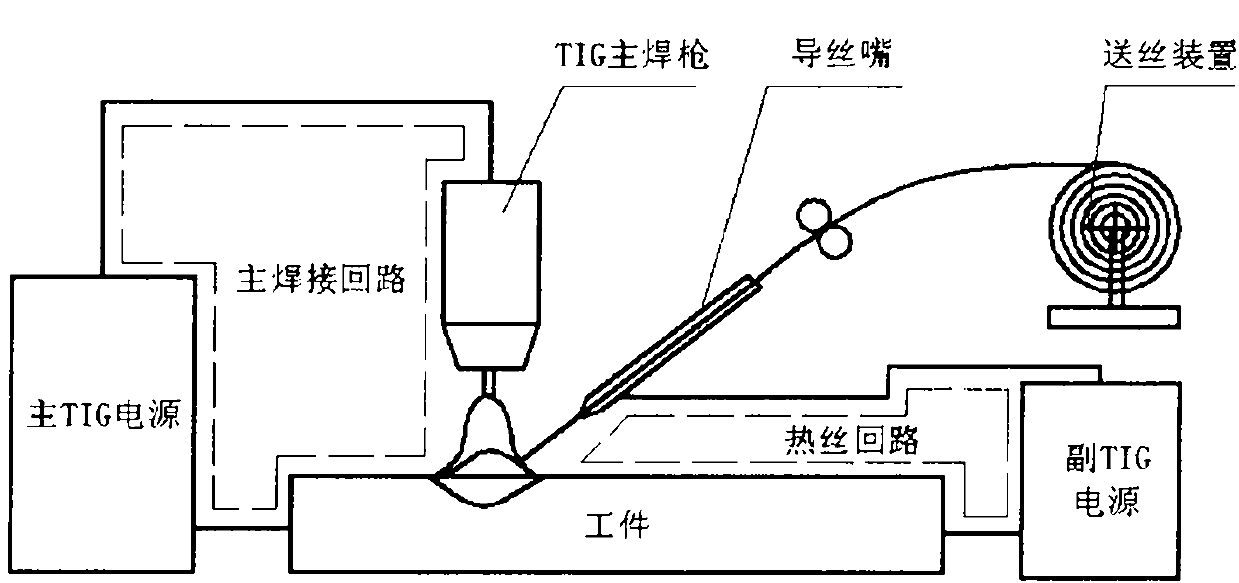

[0017] Example 1: Combination figure 1 , The present invention is a TIG power supply-assisted dual TIG composite heat source welding equipment, which is composed of a main TIG power supply, a TIG main welding torch, a wire guide nozzle, a secondary TIG power supply, a wire feeding device and a workpiece, and is characterized in that: the main TIG power supply Connect the main TIG welding torch and the workpiece respectively. The main TIG power supply, the main TIG welding torch, the main welding arc and the workpiece form the main welding circuit; the auxiliary TIG power supply is respectively connected to the wire guide and the workpiece, and the wire guide is inserted into the wire guide sent by the wire feeding device. The welding wire, the wire guide nozzle, the auxiliary TIG power source, the workpiece and the welding pool form the hot wire circuit, and the wire feeding device is insulated from the workpiece.

[0018] The welding method realized by the double TIG composit...

Embodiment 2

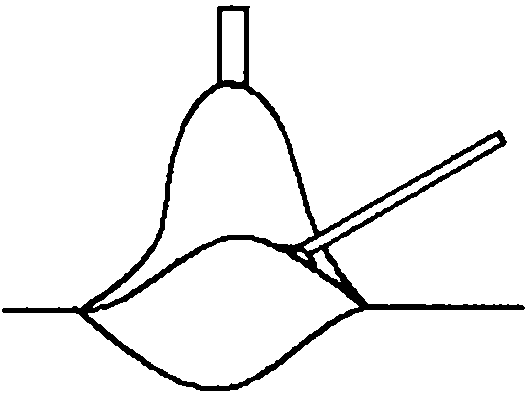

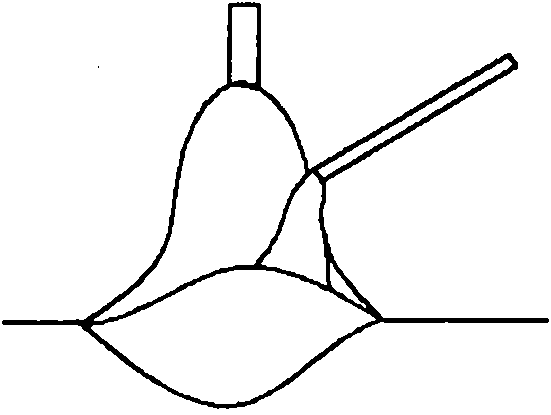

[0019] Example 2: Combination Figure 1-Figure 5 , the present invention is based on the low welding efficiency of traditional tungsten electrode argon arc welding and the limited ability of tungsten electrode to carry current, which limits its application in the field of large and thick plates and surfacing welding. A hot wire under the action of dual TIG composite power sources is proposed Welding Technology. The resistance heat or arc heat generated by the auxiliary TIG power supply is used to heat the welding wire to increase the welding heat input as a whole to make up for the heat input limitation caused by the limited carrying capacity of the tungsten electrode. It alleviates the power capacity requirement of TIG power supply, improves the service life of tungsten electrode, and improves production efficiency. Since the heat of the composite heat source is concentrated to the end of the welding wire, the heat input of the base metal is reduced, and the dissolved amount...

Embodiment 3

[0022] Example 3: Combination Figure 1-Figure 5 , the present invention introduces the auxiliary TIG power supply into the tungsten argon arc welding system, firstly, the wire feeding device and the welding wire are insulated from the workpiece, and the two electrodes of the auxiliary TIG power supply are respectively connected to the wire feeding nozzle and the workpiece to form a conductive loop, such as figure 1 shown. When the welding process starts, the main welding circuit is turned on, the main arc is ignited to preheat the workpiece for 1-2 s, and then the welding wire is fed through the wire feeding device. Under the action of the arc plasma generated by the arc, the auxiliary arc is easily ignited between the end of the welding wire and the workpiece. Under the action of the heat generated by the arc, the end of the welding wire melts and forms a droplet. As the droplet grows, the auxiliary arc The heating effect on the welding wire gradually decreases. Due to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com