Full-sea-depth brushless direct-current electric propeller with rotary cartridge mechanical seal device

A technology of electric propulsion and mechanical seal, which is applied in the field of deep sea exploration, can solve problems such as the inability to apply full-sea deep underwater submersibles, the difficulty of reaching the diving depth of 10,000 meters, and the unfavorable modular development of submersibles, and achieve a novel sealing structure. , good sealing effect, simple and reasonable combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

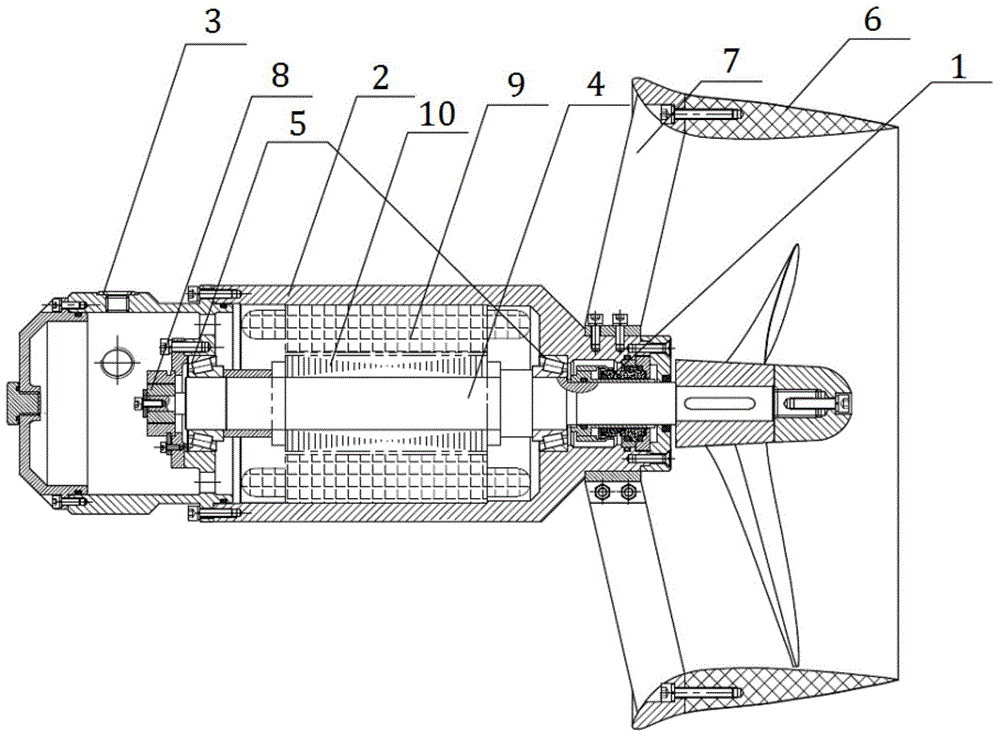

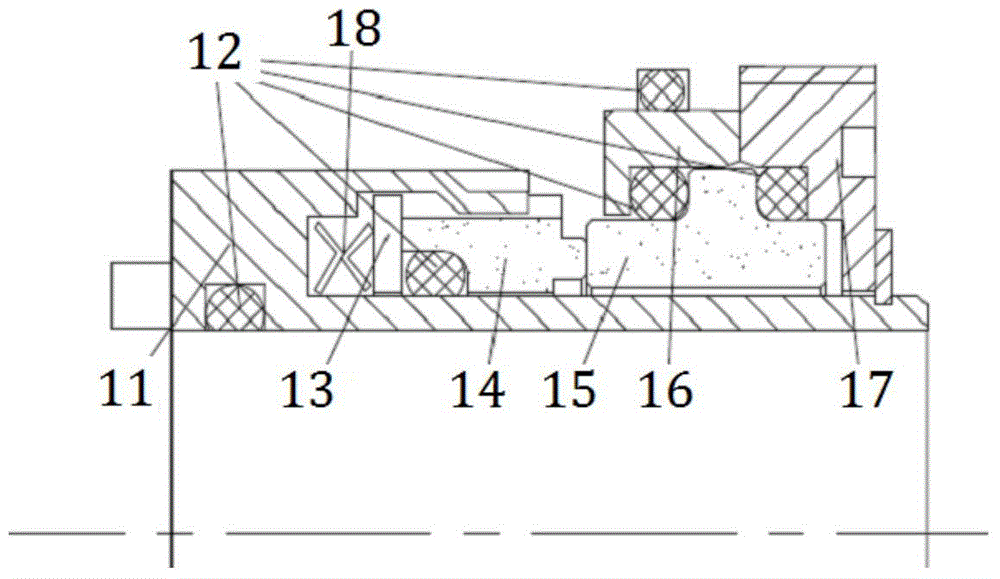

[0020] Such as figure 1 As shown, this embodiment includes: a rotary cartridge mechanical seal device 1, a propeller housing 2, a transmission shaft 4, a ducted propeller 6, a connecting bracket 7, a rotary transformer 8, a DC brushless stator 9 and its rotor 10, wherein : The rotary cartridge mechanical seal device 1 is axially sealed connected with the transmission shaft 4, the rotary transformer 8 collects the rotation speed of the transmission shaft 4 and transmits the rotation speed to the control system of the submersible through the transmission line of the hydraulic interface, and the propeller housing 2 The interference fit assembly is adopted between the DC brushless stator 9, the heat generated inside the motor is directly transmitted into the water through the propeller shell 2 through heat conduction, and the front end of the propeller shell 2 passes through the connecting bracket 7 fixed with the transition flange It is connected with duct paddle 6.

[0021] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com