Modified epoxy resin adhesive used under low temperature

An epoxy resin and adhesive technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of high thermal expansion coefficient, low glass transition temperature, poor impact toughness, etc., to improve mechanical properties, room temperature impact The effect of improving strength and tensile strength and reducing thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

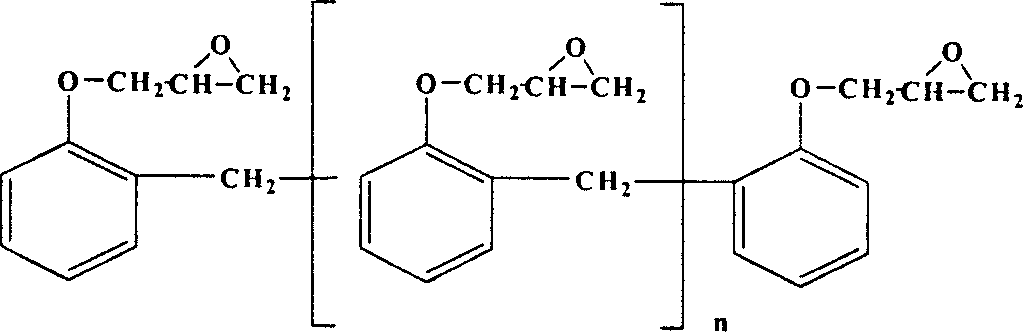

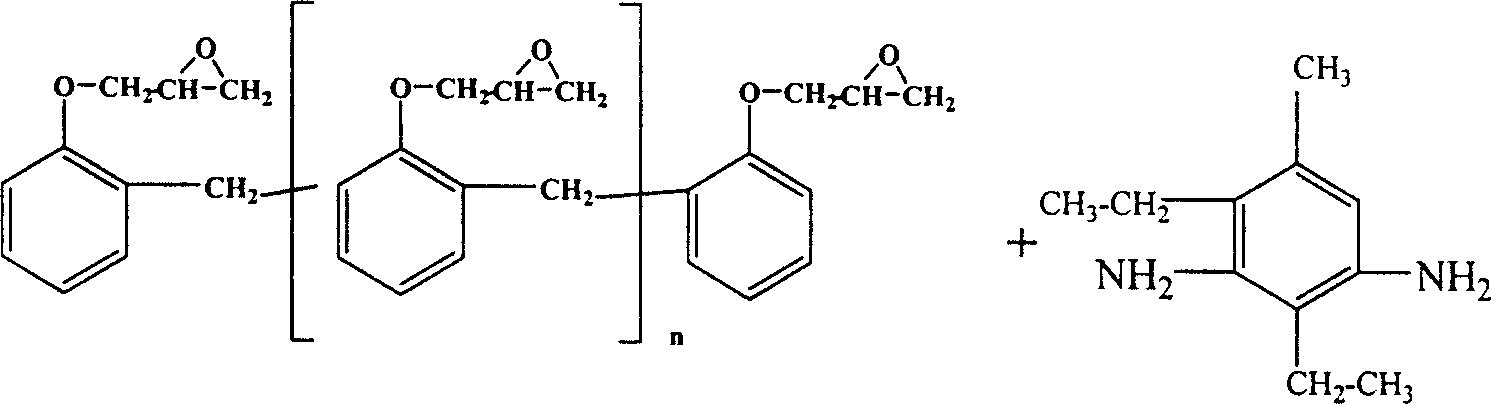

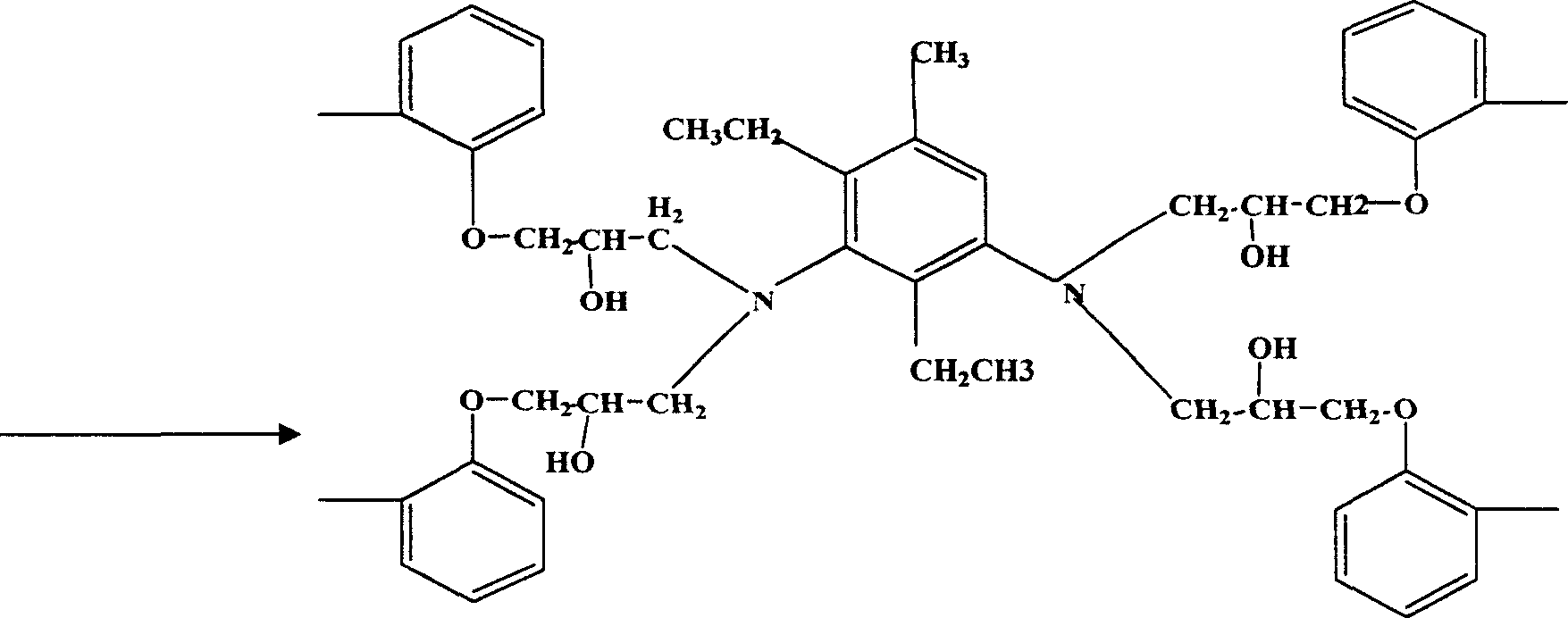

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, preparation of the introduction of 2wt% SiO of the present invention 2 Modified Epoxy Adhesives for Low Temperatures

[0027] Weigh 39.2 g of bisphenol F epoxy resin (viscosity 3000 cP.s, epoxy equivalent 160 g / mol), measure 40 ml of acetone, and dissolve bisphenol F epoxy resin in acetone. After stirring for 3-5 minutes, 4.2 ml of 25% ammonia water was added dropwise to the above solution, and after the stirring state was maintained for 10 minutes, 5.8 g of tetraethyl orthosilicate (TEOS) was slowly added dropwise to the above solution. After the dropwise addition, stir at a speed of 1000 rpm for 4 hours, and then use vacuum degassing to remove organic solvents, excess precursors or catalysts, and by-products generated during the reaction to obtain viscous liquid modified epoxy resins. Resin, namely component A;

[0028] From 50 parts by weight of the above component A, 18 parts by weight of component C—2,4-diethyl-5-methyl-1,3-phenylenediamine and 50 p...

Embodiment 2

[0032] Embodiment 2, preparation of introducing 4wt% SiO of the present invention 2 Modified Epoxy Adhesives for Low Temperatures

[0033] Weigh 39.2 g of bisphenol F epoxy resin (viscosity 5000 cP.s, epoxy equivalent 180 g / mol), measure 40 ml of acetone, and dissolve bisphenol F epoxy resin in acetone. After stirring for 3 to 5 minutes, 8.4 ml of 25% ammonia water was added dropwise to the above solution, and after maintaining the stirring state for 10 minutes, 11.6 g of tetraethyl orthosilicate (TEOS) was slowly added dropwise to the above solution. After the dropwise addition, stir at a speed of 3000 rpm for 1 hour, and then use vacuum degassing to remove organic solvents, excess precursors or catalysts, and by-products generated during the reaction to obtain viscous liquid modified epoxy resins. Resin, namely component A;

[0034] By the above-mentioned component A, 15.7g component C and 26.1g component B (same as component B and C in embodiment 1) form the introduction ...

Embodiment 3

[0038] Embodiment 3, preparation of introducing 3wt% SiO of the present invention 2 Modified Epoxy Adhesives for Low Temperatures

[0039] Weigh 54g of bisphenol F epoxy resin (viscosity 3000cP.s, epoxy equivalent 170g / mol), measure 40ml of acetone, and dissolve bisphenol F epoxy resin in acetone. After stirring for 3 to 5 minutes, 6.3 ml of 25% ammonia water was added dropwise to the above solution, and after maintaining the stirring state for 10 minutes, 8.7 g of tetraethyl orthosilicate (TEOS) was slowly added dropwise to the above solution. After the dropwise addition, stir at a speed of 2000 rpm for 2 hours, and then use vacuum degassing to remove organic solvents, excess precursors or catalysts, and by-products generated during the reaction to obtain viscous liquid modified epoxy resins. Resin, namely component A;

[0040] By the above-mentioned component A, 13.5g component B and 13.5g component C (same as component B and C in embodiment 1) form the introduction 3wt% S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com