Transparent film, transparent conductive laminate, and touch panel, solar cell and display device, using same

A technology of transparent conductivity and transparent film, which is applied to the conductive layer on the insulating carrier, transportation and packaging, semiconductor devices, etc., can solve the problems of inapplicability, and achieve the suppression of quality deterioration, excellent heat resistance, and high thermal shock resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0186] The linear expansion coefficients of the substrate films obtained in Examples 1 to 7 and Comparative Examples 1 to 2 can be determined by using a sample with a length of 20 mm, a width of 5 mm, and a thickness of 0.05 mm (50 μm), and a thermomechanical analyzer ( Rigaku product name "TMA8310"), under the conditions of tensile mode (49mN) and heating rate of 5°C / min under nitrogen atmosphere, the length change of the sample at 50°C to 200°C was measured, and 50 The average value of the length change per 1°C in the temperature range from °C to 200°C was measured. In addition, with respect to the substrate film used in Comparative Example 3, the linear expansion coefficient was measured in the same manner as in Example 1 except that the thickness of the sample was set to 0.1 mm (100 μm).

[0187]

[0188] The refractive index of the substrate film etc. obtained in each Example and each comparative example was measured using a refractive index measuring device (trade name...

Synthetic example 1

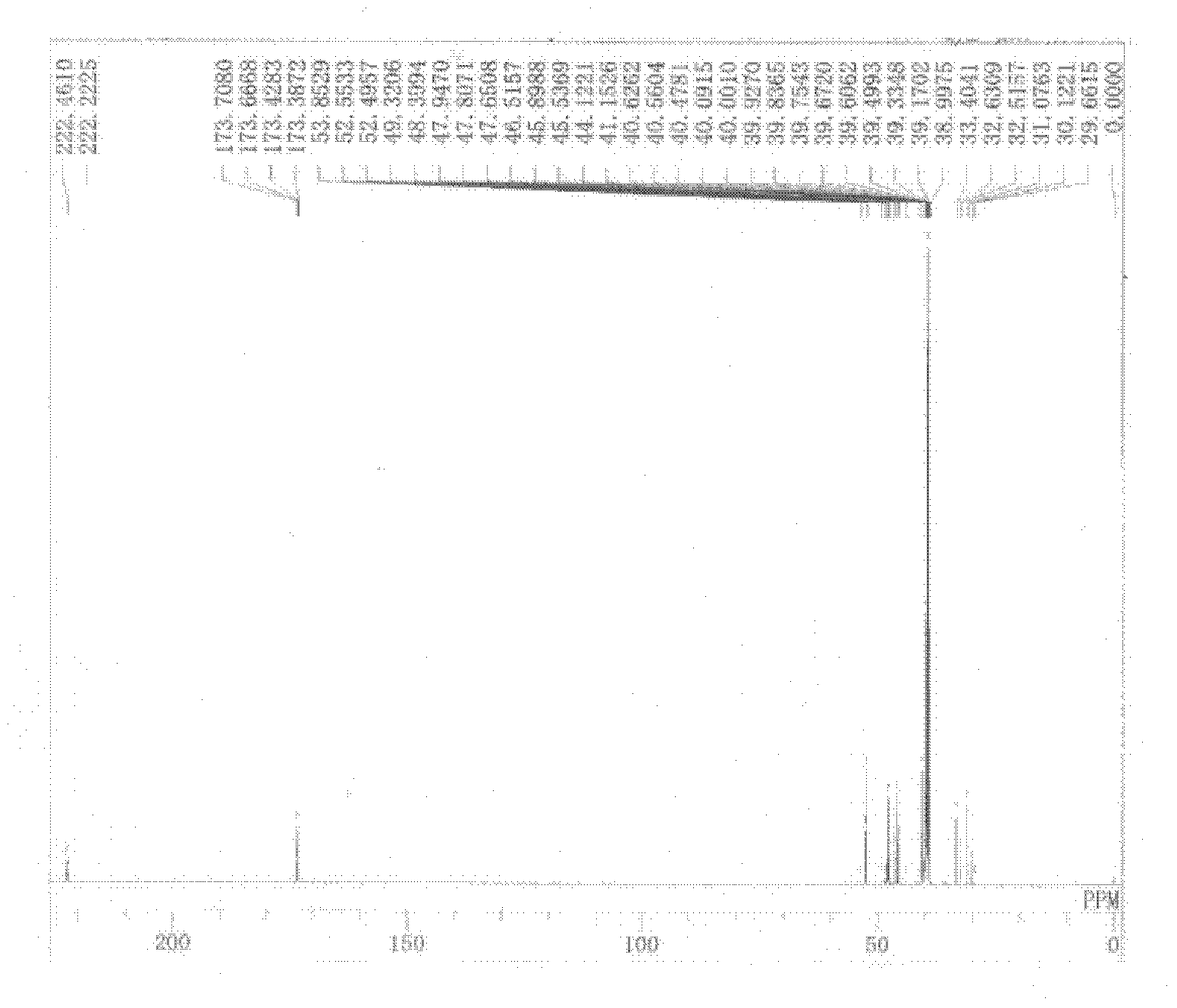

[0195] (Synthesis Example 1: Synthesis of tetracarboxylic dianhydride)

[0196] First, 6.83 g (dimethylamine: 75.9 mmol) of a 50% by mass dimethylamine aqueous solution was added to a 100 ml two-necked flask. Next, 8.19 g (hydrogen chloride: 78.9 mmol) of 35 mass % hydrochloric acid aqueous solution was added to the 100 ml dropping funnel. Next, install the dropping funnel on the two-necked flask, add the hydrochloric acid aqueous solution dropwise in the dimethylamine aqueous solution under ice-cooling, and prepare dimethylamine hydrochloride in the two-necked flask. . Next, 2.78 g (92.4 mmol) of paraformaldehyde and 2.59 g (30.8 mmol) of cyclopentanone were further added to the two-necked flask. Next, after installing a spherical condenser on the two-necked flask, the inside of the two-necked flask was replaced with nitrogen. Thereafter, the two-necked flask was immersed in an oil bath at 90°C, and heated and stirred for 3 hours to obtain a compound represented by the abo...

Embodiment 1)

[0205] First, heat a 30ml three-necked flask with a heat gun to fully dry it. Next, the atmosphere gas in the sufficiently dried three-necked flask was replaced with nitrogen, and the inside of the three-necked flask was made into a nitrogen atmosphere. Next, 0.1337 g (0.63 mmol: manufactured by Tokyo Chemical Industry Co., Ltd.: OTD) and 0.0541 g (0.27 mmol: manufactured by Wakayama Seika Kogyo Co., Ltd.: DDE) 4,4'- After the diaminodiphenyl ether, further add 2.7g of N,N-dimethylacetamide, and dissolve the aromatic diamine compound (ortho-toluidine ( OTD) and 4,4'-diaminodiphenyl ether (DDE)) to obtain a solution. Next, the three-necked flask containing the solution was submerged in a dry ice-acetone bath, and cooled to solidify the solution.

[0206] Next, 0.3459 g (0.90 mmol) of norbornane-2-spiro-2'-cyclopentanone-5'- After spiro-2”-norbornane-5,5”,6,6”-tetracarboxylic dianhydride, the temperature of the solution was returned to room temperature (25°C), under nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com