Mullite-whisker-reinforced anorthite porous ceramic and preparation method thereof

A technology of mullite whiskers and porous ceramics, which is applied in the field of mullite whisker-reinforced anorthite porous ceramics and its preparation, can solve problems such as low thermal conductivity, and achieves high yield, easy operation, and morphology. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a specific example of the preparation method of mullite whisker reinforced anorthite porous ceramics of the present invention, the raw materials used are mullite whisker powder, α-Al 2 o 3 , CaCO 3 and SiO 2 , the purity is analytically pure, the molar ratio of ingredients is 1:1:2, and the designed mullite whisker content is 50wt.%. The detailed preparation steps are as follows:

[0037] 1) Prepare the premix;

[0038]The solid content of the ceramic slurry is 25vol.%. Weigh 37.5g of deionized water into the beaker, weigh 3.75g of acrylamide powder and add it to the above beaker, weigh 0.38g of N,N'-methylenebisacrylamide and add it to the above beaker, and weigh the dispersant ammonium polyacrylate 0.19 g was placed in the above beaker. Then use JJ-1 type precision booster electric stirrer to mechanically stir to prepare the premix, the stirring speed is 2000 rpm, and the stirring time is about 30 minutes.

[0039] 2) preparing a homogeneously mixed ceramic ...

example 1

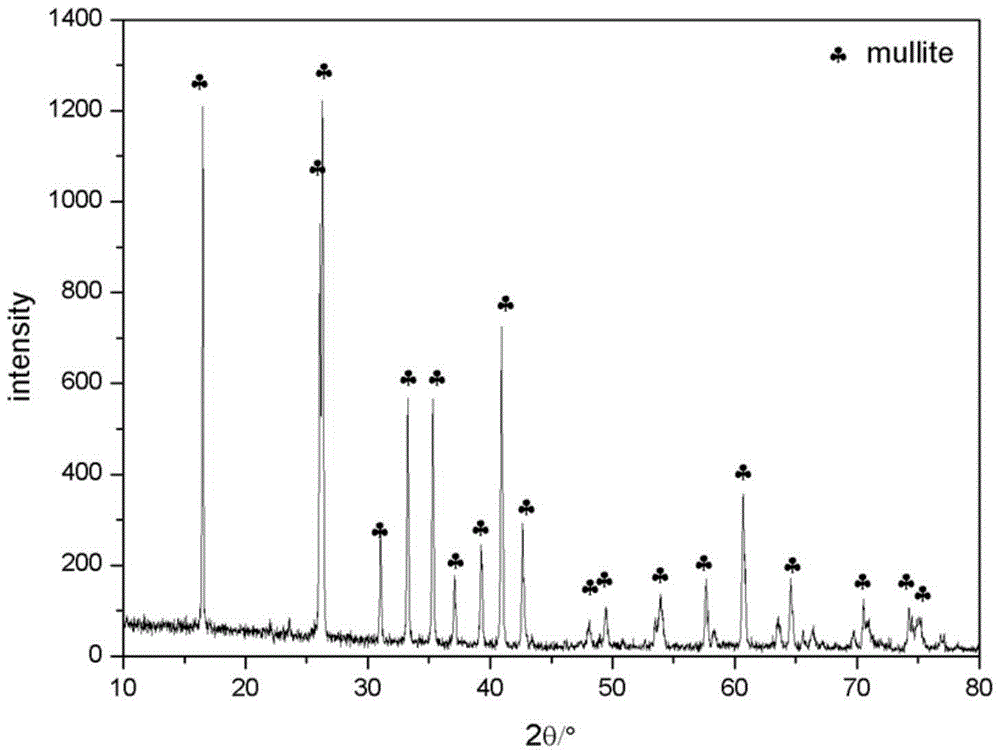

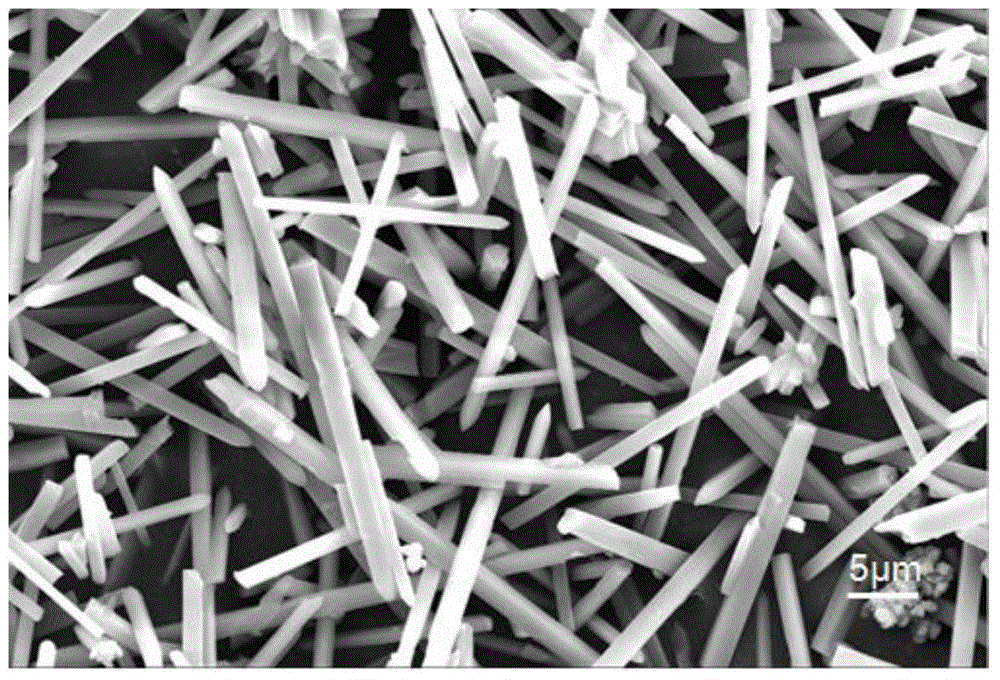

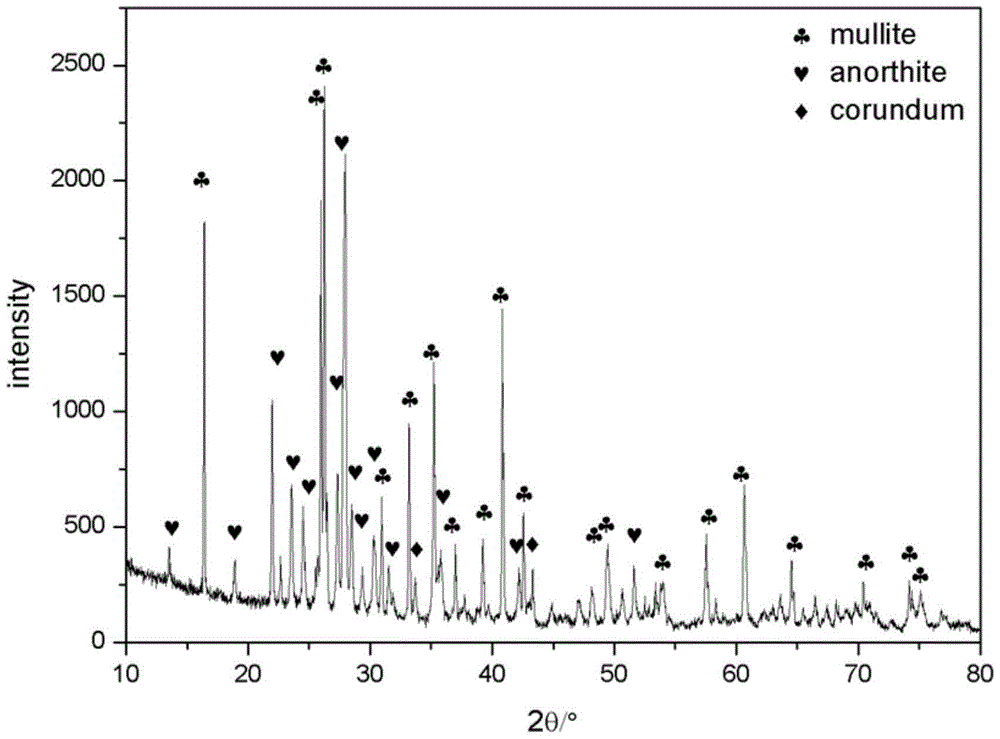

[0049] The XRD diffraction pattern of the mullite whisker reinforced anorthite porous ceramics that example 1 finally prepares is as attached image 3 As shown, the main components are mullite and anorthite, and a small amount of corundum phase exists; the typical microstructure is as attached Figure 4 As shown, mullite whiskers are attached to the pore walls of the prepared porous ceramics, and the whiskers are closely combined with the anorthite matrix. There is no agglomeration of the whiskers, and the dispersion is relatively uniform. The existence of the whiskers does not affect the formation of pores. Under high magnification, it can be found that the whiskers overlap each other, and the anorthite grains are attached to the overlaps and the surface of the whiskers; the physical properties of the prepared anorthite porous ceramics are as follows: the apparent porosity is 90.30±0.24%, Bulk density 0.278±0.008g / cm 3 , room temperature vacuum thermal conductivity 0.045±0.0...

Embodiment 2

[0051] The raw materials used are mullite whisker powder, α-Al 2 o 3 , CaCO 3 and SiO 2 , the purity is analytically pure, the molar ratio of anorthite ingredients is 1:1:2, and the designed mullite whisker content is 60mol%. The detailed preparation steps are as follows:

[0052] 1) Prepare the premix;

[0053] The solid content of the ceramic slurry is 25vol.%. Weigh 52.5g of deionized water into the beaker, weigh 5.25g of acrylamide powder and add it to the above beaker, weigh 0.53g of N,N'-methylenebisacrylamide and add it to the above beaker, and weigh the dispersant ammonium polyacrylate 0.3 g was placed in the above beaker. Then use JJ-1 type precision booster electric stirrer to mechanically stir to prepare the premix, the stirring speed is 2000 rpm, and the stirring time is about 30 minutes.

[0054] 2) preparing a homogeneously mixed ceramic slurry;

[0055] First, pour the above-mentioned uniformly mixed premix into a ball mill jar with a certain amount of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com